Methods for making silicon containing films on thin film transistor devices

A silicon-containing film and device technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Example 1: Deposition of diethylsilane (2ES) and triethylsilane (3ES) at deposition temperatures of 200°C, 250°C, 300°C, 350°C and 400°C

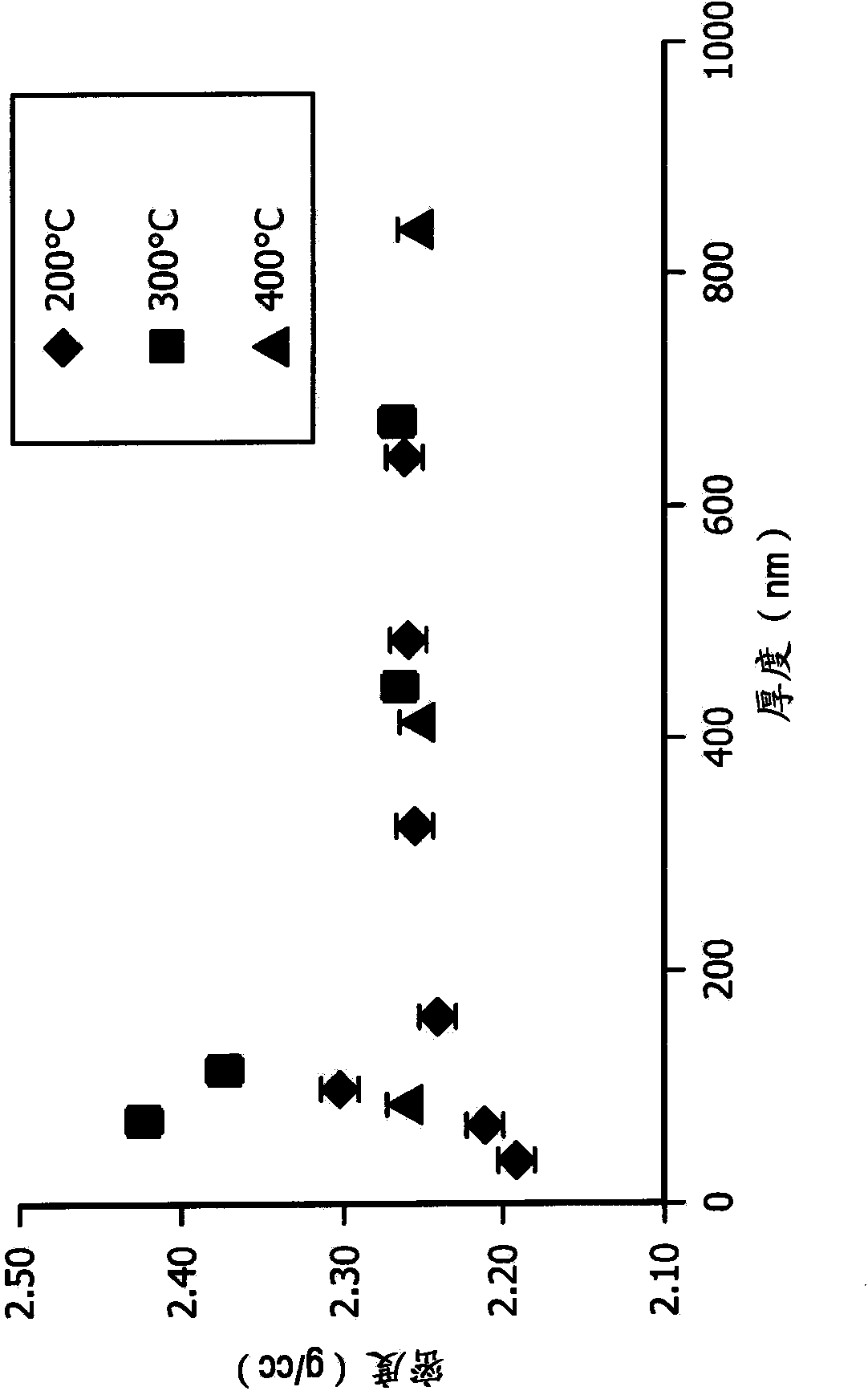

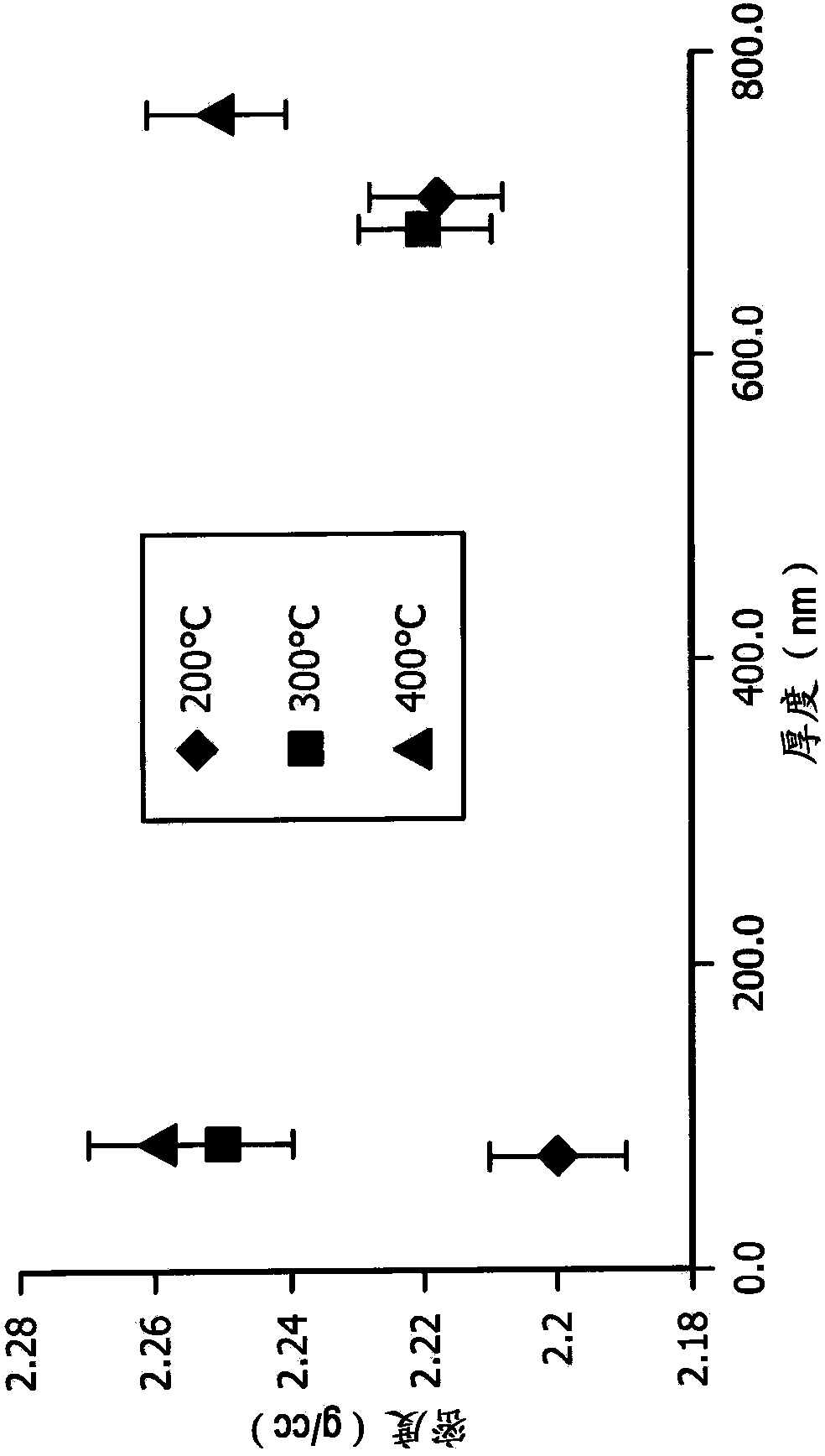

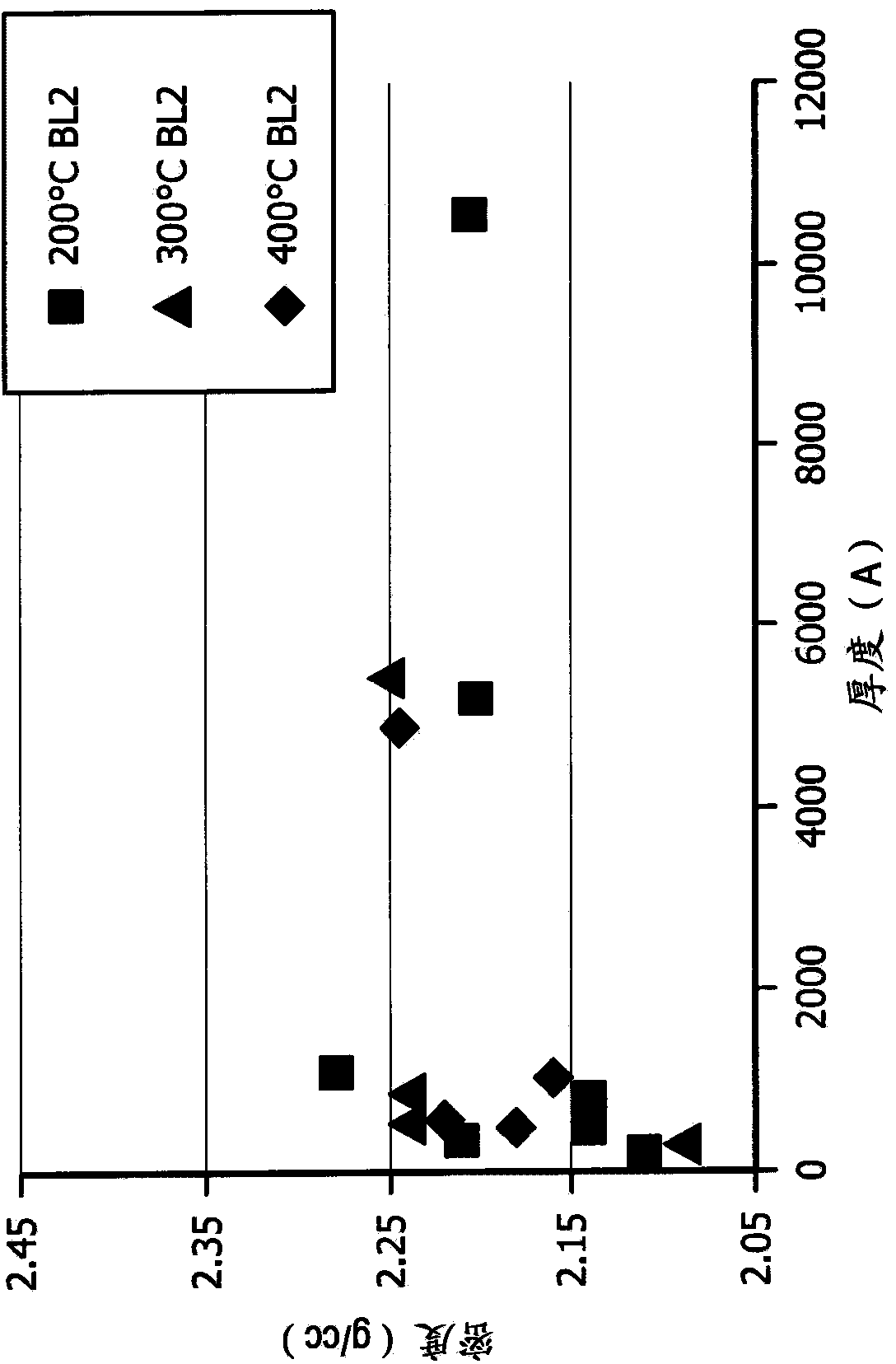

[0098] Silicon oxide films were deposited from silicon precursors 2ES and 3ES. SiO was deposited at different temperatures and process conditions using the general deposition conditions described above 2 membrane. BL-1 and BL-2 conditions were the same except for the precursor flow rate. Although the BL-1 process has the highest deposition rate due to the higher precursor flow rate, for the gate insulating layer, the deposition rate is not the most important criterion. BL-3 is a lower pressure condition and generally gives a poorer membrane. A comparison of the same Si-feed amount between the precursors was used to see if a truly better quality film could be produced. Such as Figure 1A and 2A As seen in , for >200nm films using the BL-2 process, generally higher densities (>2.2g / cc) are obtained, and as Figure 1B , 2B As se...

Embodiment 2

[0104] Example 2: Comparison of silicon oxide films deposited using BL2 process conditions and tetraethoxysilane (TEOS) versus diethylsilane (2ES)

[0105] Deposit SiO using the process conditions described in General Deposition Conditions above and in Table 1 2 membrane. exist Figure 1C and 1D TEOS-deposited silicon oxide films with different thicknesses were deposited under the same BL-2 and BL-3 process conditions described in Table 1 above. refer to Figure 1C , compared with 2ES and 3ES films deposited at the same deposition temperature using BL-2 (see Figure 1A and Figure 2A ) at lower deposition temperatures such as 200 °C, TEOS-deposited films generally have lower densities than 2ES or 3ES films. For the same deposition temperature, comparing Figure 1D The data in and the data of 2ES film and 3ES film ( Figure 1B and 2B A similar effect was observed for . 2ES and 3ES films typically exhibit the same or higher densities for thinner films. In general, the...

Embodiment 3

[0112] Example 3: Deposition of thin SiO with high density using 3ES 2 Membrane and Electrical Properties

[0113] Process conditions for 3ES silicon oxide films were screened using the Design of Experiments (DOE) approach summarized below: precursor flow rate 10 to 200 sccm; O 2 / He flow rate 100 to 1000 sccm, pressure 0.75 to 10 Torr; low frequency (LF) power 0 to 100W; deposition temperature range 25 to 350°C. DOE experiments were used to determine what process parameters yield optimal films for use as gate insulating layers in display devices.

[0114] SiO was deposited using precursor 3ES at even lower deposition temperatures such as 100°C, 125°C and 150°C than those described in the previous examples above 2 membrane. High density and thin SiO obtained by optimizing process parameters such as precursor flow rate, chamber pressure and power density 2 membrane. Table 2 shows the three process conditions for 3ES films deposited at different temperatures: 100°C, 125°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com