Small mouth, double-layer thin-walled energy-saving and emission-reducing stove

An energy-saving, emission-reducing, and thin-walled technology, which is applied in the field of energy-saving stoves, can solve problems such as high exhaust gas temperature, low energy utilization rate, and poor combustion effect of wood stoves, achieving high combustion temperature, eliminating fire hazards, and small smoke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Al 2 0 3 50%, refractory cement 25%, cordierite powder 6%, mullite powder 6%, titanium slag 2%, SiO 2 7%, graphite 2%, and MgO2% are mixed according to the weight ratio, then mixed with 12% water and stirred, poured into the mold at room temperature and molded for 4 days, and the finished product is obtained.

Embodiment 2

[0029] Embodiment 2: Al 2 0 3 57%, refractory cement 18%, cordierite powder 5%, mullite powder 5%, titanium slag 2%, SiO 2 7%, 3% graphite, and 3% MgO are mixed according to the weight ratio, then mixed with 15% water by weight, poured into the mold for 4 days at room temperature, and the finished product is obtained.

Embodiment 3

[0030] Embodiment 3: Al 2 0 3 60%, refractory cement 15%, cordierite powder 4%, mullite powder 4%, titanium slag 2%, SiO 2 7%, 4% graphite, and 4% MgO are mixed according to the weight ratio, then added with 18% water and stirred, poured into the mold at room temperature and molded for 4 days to obtain the finished product.

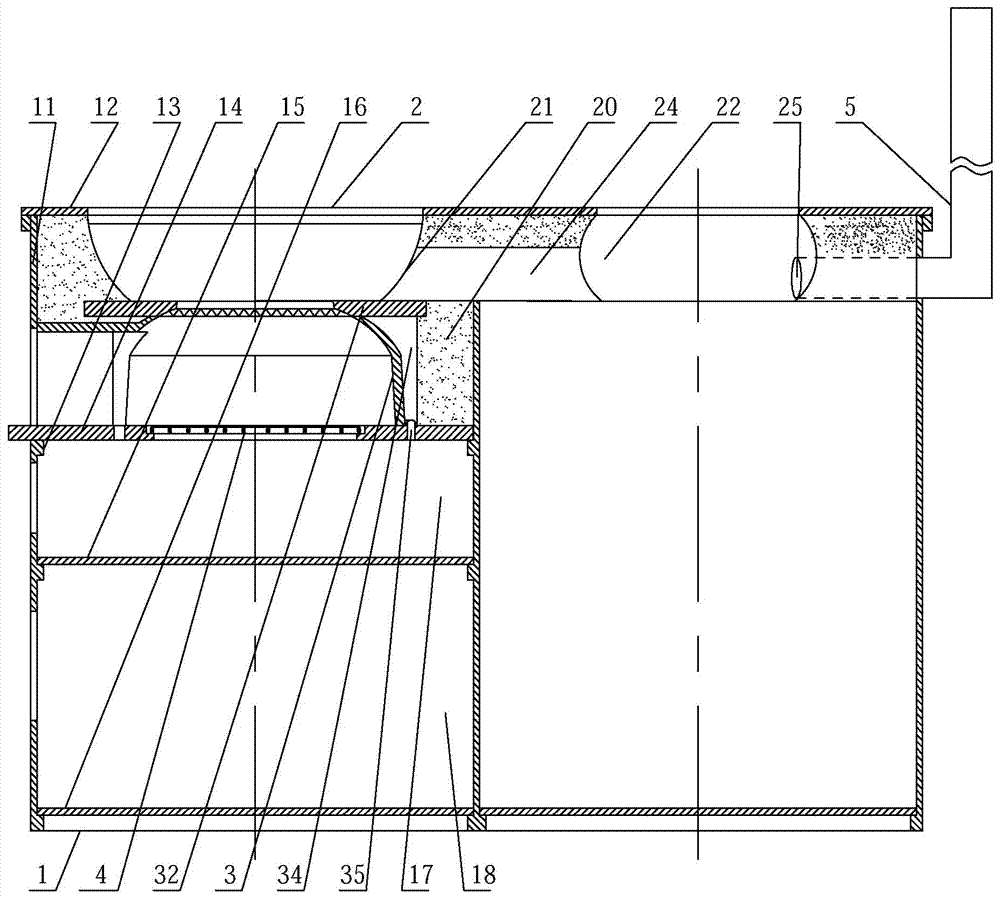

[0031] When this small-mouth, double-layer thin-walled energy-saving and emission-reducing stove is in use, air enters the stove chamber 3 through the air duct 17 and the gap of the grate 4 to promote fuel combustion to generate heat energy, and the air sent into the secondary air inlet 35 passes through the cavity 34 and the V-shaped The gap between the grooves of the groove cover plate 32 is sent into the top muzzle 30 of the stove chamber 3, supplemented with oxygen to support combustion, and the fuel is fully oxidized. The unique design of the combustion chamber with a large bottom and a small top in the hearth 3 can oxidize and burn the fuel. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com