High-W-content Ni-based amorphous alloy and preparation method thereof

An amorphous alloy and content technology, which is applied in the field of amorphous alloy material preparation, can solve the problems of increased energy consumption, complex composition, limited application, etc., and achieves the effects of low cost, simple composition, and simple amorphous composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) By atomic fraction, the Ni content is 68.6%, the W content is 17.9%, the B content is 13.5%, and 50g of the material is prepared.

[0045] (2) Mix the ingredients in a roller ball mill for 6 hours at a speed of 200r / min, then press them into blocks at 200MPa, the diameter of the green body is 20mm, pre-fire at 850°C for 1.5 hours in a hydrogen atmosphere, and take out the furnace in three times to avoid oxidation .

[0046] (3) Put the pre-fired compact into a non-consumable vacuum arc melting furnace and vacuumize to 1×10 -5 Pa, then fill it with high-purity argon to 0.05MPa, and conduct 6 times of arc melting after the molten titanium absorbs oxygen.

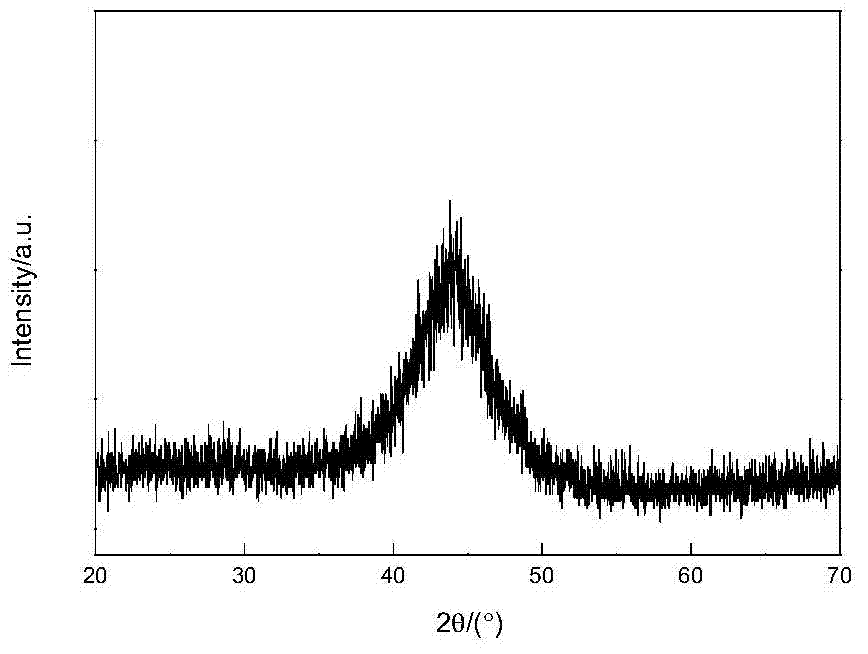

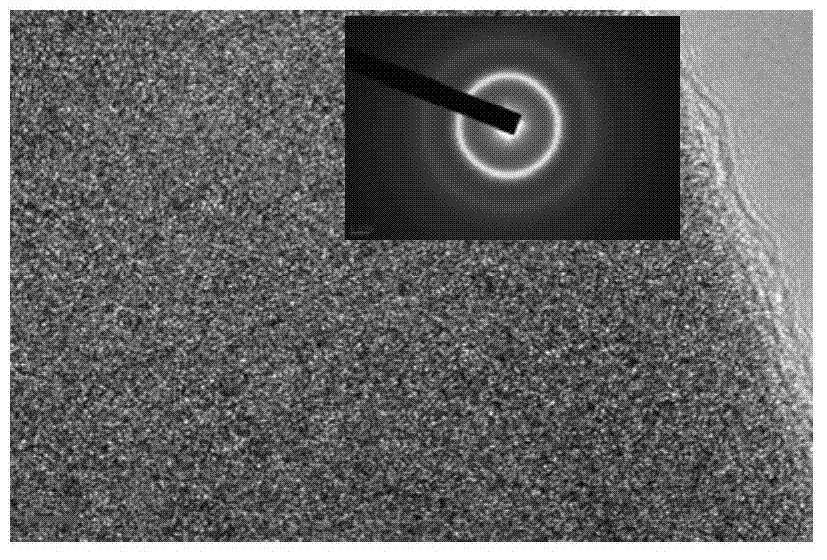

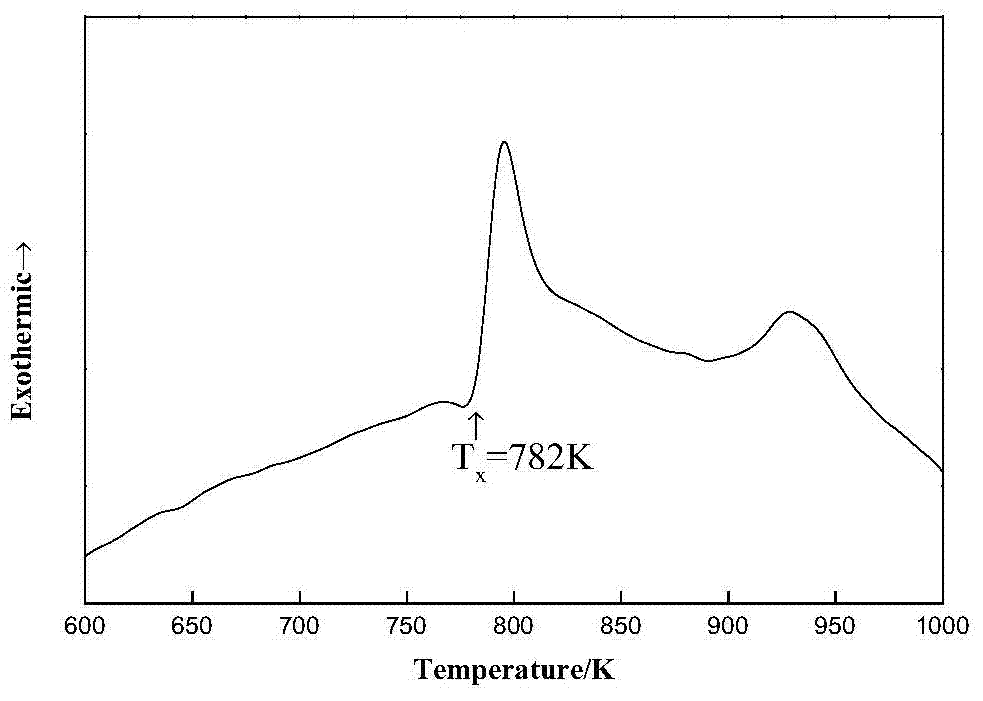

[0047] (4) Put 4 g of uniformly smelted master alloy into a quartz tube, and place it in a vacuum belt throwing machine to prepare amorphous strips with high tungsten content, and the copper roller rotates at a speed of 30 m / s. The microhardness measured by a micro Vickers hardness tester is 8.5GPa, and the crysta...

Embodiment 2

[0049] (1) By atomic fraction, the Ni content is 66.6%, the W content is 19.9%, and the B content is 13.5%, and 50g of the material is prepared.

[0050] (2) Mix the ingredients in a roller mill for 6 hours at a speed of 200r / min, then press them into blocks at 200MPa, the diameter of the green body is 20mm, pre-fire at 860°C for 1.5 hours, and take out the furnace in three times to avoid oxidation .

[0051] (3) Put the pre-fired compact into a non-consumable vacuum arc melting furnace and vacuumize to 1×10 -5 Pa, then fill it with high-purity argon to 0.05MPa, and conduct 6 times of arc melting after the molten titanium absorbs oxygen.

[0052] (4) Put 5 g of uniformly smelted master alloy into a quartz tube, and place it in a vacuum belt throwing machine to prepare amorphous strips with high tungsten content, and the copper roller rotates at a speed of 30 m / s. The microhardness measured by a micro Vickers hardness tester is 10.2GPa, and the crystallization temperature mea...

Embodiment 3

[0054] (1) In terms of atomic fraction, the Ni content is 60.6%, the W content is 17.9%, the Nb content is 8%, and the B content is 13.5%, and 55g of the material is prepared.

[0055] (2) Mix the ingredients in a roller ball mill for 6 hours at a speed of 200r / min, then press them into blocks at 200MPa, the diameter of the green body is 20mm, pre-fire at 900°C for 1.5 hours in a hydrogen atmosphere, and take out the furnace in three times to avoid oxidation .

[0056] (3) Put the pre-fired compact into a non-consumable vacuum arc melting furnace and vacuumize to 1×10 -5 Pa, then fill it with high-purity argon to 0.05MPa, and conduct 6 times of arc melting after the molten titanium absorbs oxygen.

[0057] (4) Put 6g of uniformly smelted master alloy into a quartz tube, and place it in a vacuum belt throwing machine to prepare an amorphous strip with high tungsten content, and the copper roller rotates at a speed of 30m / s. The microhardness measured by a micro Vickers hardne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com