Short-process manufacturing method of cold rolling non-oriented high-silicon steel sheet

A manufacturing method and high-silicon steel technology, which is applied in the field of electrical steel plate manufacturing, can solve the problems of complex production process of high-silicon steel sheet, deterioration of product surface quality, and many manufacturing processes, so as to avoid bad shape, good shape, and surface quality excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

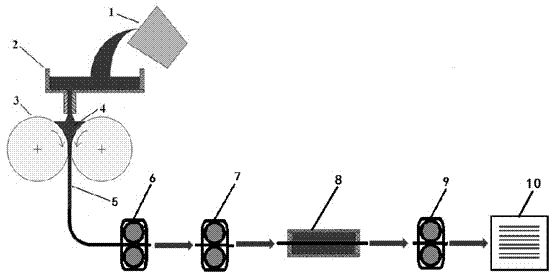

[0023] (1) Smelting: use melting furnace 1 to smelt molten steel that meets the chemical composition requirements of high-silicon steel, and obtain the chemical composition by weight percentage: Si: 6.4%, Al: 0.06%, Mn: 0.3%, Cr: 0.2%, N : 0.0033%, S: 0.0038%, P: 0.0066%, O: 0.002%, C: 0.004%, the balance is liquid high silicon steel of Fe;

[0024] (2) Casting and rolling: the above-mentioned liquid high silicon steel molten steel is cast into the tundish 2 at 1450°C, and the molten steel flows through the tundish into the cavity composed of two counter-rotating crystallization rollers 3 and side sealing plates to form a molten pool 4. The degree of superheat of the molten steel on the upper surface of the molten pool 4 is 10°C. The molten steel in the molten pool 4 is solidified by the crystallization roll, and the casting and rolling speed of the crystallization roll is controlled to be 80m / min, and a non-oriented high-silicon steel sheet with a thickness of 1mm and a width ...

Embodiment 2

[0031] (1) Smelting: use melting furnace 1 to smelt molten steel that meets the chemical composition requirements of high-silicon steel, and obtain the chemical composition by weight percentage: Si: 6.5%, Al: 0.08%, Mn: 0.5%, Cr: 0.5%, N : 0.0028%, S: 0.0034%, P: 0.0087%, O: 0.003%, C: 0.003%, the balance is liquid high silicon steel of Fe;

[0032] (2) Casting and rolling: the above-mentioned liquid high silicon steel molten steel is cast into the tundish 2 at 1500°C, and the molten steel flows through the tundish into the cavity composed of two counter-rotating crystallization rollers 3 and side sealing plates to form a molten pool 4. The degree of superheat of the molten steel on the upper surface of the molten pool 4 is about 60°C. The molten steel in the molten pool 4 is solidified by the crystallization roller, and the casting and rolling speed of the crystallization roller is controlled to 40m / min, and a non-oriented high-silicon steel with a thickness of 2mm and a width...

Embodiment 3

[0039] (1) Smelting: use melting furnace 1 to smelt molten steel that meets the chemical composition requirements of high-silicon steel, and obtain the chemical composition by weight percentage: Si: 6.6%, Al: 1.0%, Mn: 0.8%, Cr: 1.0%, N : 0.0033%, S: 0.0029%, P: 0.0056%, O: 0.002%, C: 0.005%, the balance is liquid high silicon steel of Fe;

[0040](2) Casting and rolling: the liquid high-silicon steel molten steel mentioned above is cast into the tundish 2 at 1450°C, and the molten steel flows through the tundish into a cavity composed of two counter-rotating crystallization rollers 3 side sealing plates to form a molten pool 4 , the degree of superheat of the molten steel on the upper surface of the molten pool 4 is 100°C, the molten steel in the molten pool 4 is solidified by the crystallization roller, and the casting and rolling speed of the crystallization roller is controlled to be 20m / min, and a non-oriented high-silicon steel strip with a thickness of 3mm and a width of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com