Aspergillus niger seed liquid preparation method and citric acid fermentation preparation method

A technology of Aspergillus niger spores and Aspergillus niger, which is applied in the field of preparation of Aspergillus niger seed liquid, can solve the problems of Aspergillus niger spores absorbing water and swelling, long germination time, affecting the quality of Aspergillus niger seed liquid, and affecting the level of citric acid fermentation, etc., reaching The effect of shortening the cultivation time, considerable economic and social benefits, and improving the fermentation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

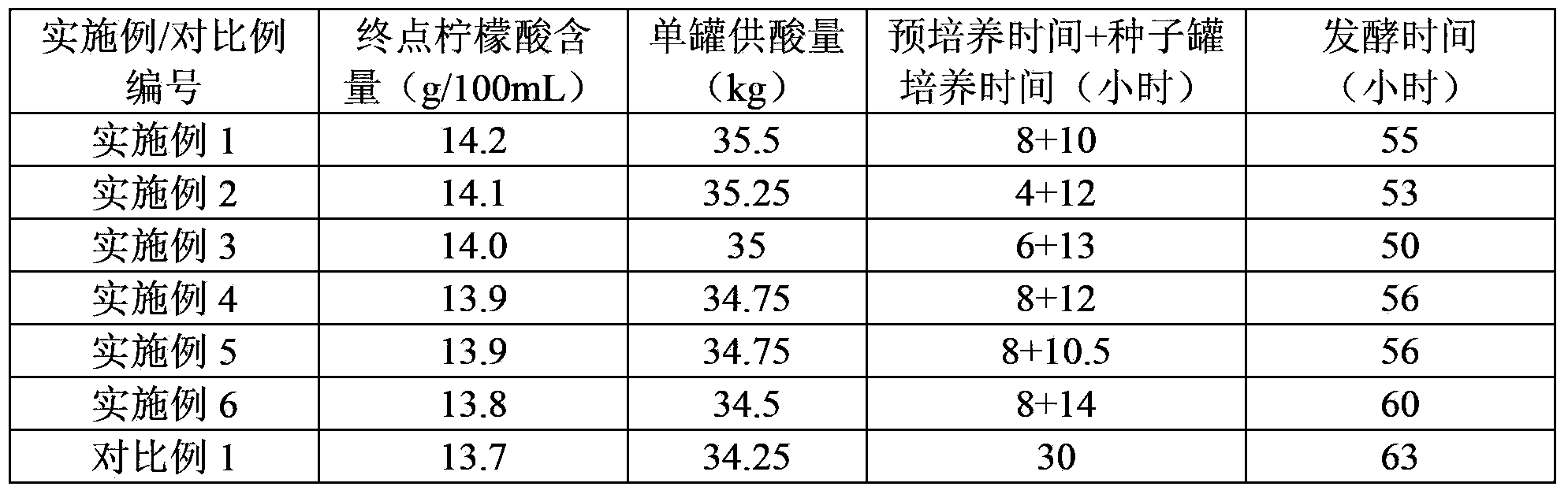

Examples

preparation example Construction

[0012] According to the method for preparing Aspergillus niger seed liquid of the present invention, the method comprises inoculating Aspergillus niger into the seed culture solution for culturing, wherein the method further comprises inoculating Aspergillus niger into the seed culture solution for culturing, and before culturing the Aspergillus niger spores The pre-culture is performed, and the conditions of the pre-culture include: a pH value of 6.2-7.2.

[0013] The inventor of the present invention found that when the pH value of the pre-culture is adjusted to 6.5-7.2, the object of the present invention can be further achieved. Therefore, preferably, the pre-culture conditions include: a pH value of 6.5-7.2.

[0014] According to the preparation method of Aspergillus niger seed liquid of the present invention, the method for adjusting the pH value may be a method commonly used in the art, for example, adjusting with an alkaline reagent; the alkaline reagent may be various alka...

Embodiment 1

[0053] This example is used to illustrate the preparation method of Aspergillus niger seed liquid and citric acid provided by the present invention.

[0054] (1) Preparation of fermentation medium

[0055] The harvested 56 kilograms of corn were crushed to obtain a crushed product with an average particle diameter of 380 microns. The crushed product was slurried at a concentration of 27% by weight. For each gram of crushed product, 50 enzyme activity units were added. The amylase (Novozymes, alpha-amylase, in the embodiments of the present invention) enters the ejector, and enzymatically hydrolyzes at 95°C and pH 5.8 for 110 minutes to obtain an enzymatic hydrolyzed liquid , The enzymatic hydrolysis liquefied liquid obtained by the enzymatic hydrolysis is filtered by a hydraulic plate and frame filter press to separate the liquefied supernatant liquid and the enzymatic hydrolysis residue. The solid content of the enzymatic hydrolysis residue is 50% by weight, and the 177.1 kg The ...

Embodiment 2

[0064] This example is used to illustrate the preparation method of Aspergillus niger seed liquid and citric acid provided by the present invention.

[0065] The citric acid fermentation was carried out by the same method as in Example 1, except that the culture process of Aspergillus niger was as follows:

[0066] Pre-culture

[0067] Take 360 bottles of 35L mature bran koji, rinse with sterile water and filter, stir at 300rpm for 60min; then ultrasonically treat for 20min at a frequency of 40,000 to obtain 30L of a uniformly dispersed spore suspension, in which the spore concentration is 7.0× 10 8 Spores / ml, take 7.5L of the spore suspension, add dropwise a 35% by weight aqueous sodium hydroxide solution to the spore suspension to make the pH value 7.2, and then add the embodiment to the spore suspension 1. The enzymatic hydrolysis liquefaction solution prepared in step (1) is such that based on the total volume of the spore suspension, the sugar concentration is 5% by weight. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com