High-temperature-resistant anti-photoaging degradable PE membrane and preparation method thereof

A technology of light aging resistance and high temperature resistance is applied in the field of high temperature and light aging degradable PE film and its preparation, which can solve the problems of accelerated aging, affecting the service life, limiting the application of polyethylene film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A degradable PE film with high temperature and light resistance and aging resistance, comprising: 55 parts of PE, 0.5 part of antioxidant 245, 0.3 part of auxiliary antioxidant TNP, 1 part of light stabilizer 944, 5 parts of polyester fiber, 2 parts of silica gel powder, 1 part of vegetable oil, 0.5 part of butyl titanate, 1 part of sorbic acid, 5 parts of hydroxypropyl starch, and 1 part of hydroxypropyl methylcellulose.

[0023] The preparation method of the high temperature and light aging resistance degradable PE film described above, the steps are as follows:

[0024] Step 1: Add PE, polyester fiber, silica gel powder, butyl titanate and hydroxypropyl methylcellulose into the reaction kettle, and stir for 30 minutes at a temperature of 80°C and a vacuum of 0.02MPa. , the stirring speed is 80 revs / min, and mixture 1 is obtained;

[0025] Step 2, adding the remaining components into the mixture 1 obtained in the step 1, stirring and mixing evenly, specifically stirr...

Embodiment 2

[0029] A degradable PE film with high temperature and light resistance and aging resistance, comprising: 60 parts of PE, 0.8 parts of antioxidant 264, 0.4 part of auxiliary antioxidant TNP, 1.2 parts of light stabilizer 770, 6 parts of polyester fiber, 3 parts of silica gel, 3 parts of vegetable oil, 0.8 parts of butyl titanate, 2 parts of sorbic acid, 7 parts of hydroxypropyl starch, 2 parts of hydroxypropyl methylcellulose.

[0030] The preparation method of the high temperature and light aging resistance degradable PE film described above, the steps are as follows:

[0031] Step 1: Add PE, polyester fiber, silica gel powder, butyl titanate and hydroxypropyl methylcellulose into the reaction kettle, and stir for 32 minutes at a temperature of 85°C and a vacuum of 0.03MPa. , the stirring speed is 85 revs / min, and mixture 1 is obtained;

[0032] Step 2, adding the remaining components to the mixture 1 obtained in the step 1, stirring and mixing evenly, specifically, stirring ...

Embodiment 3

[0036] A degradable PE film with high temperature resistance, light aging resistance, and components by weight: 63 parts of PE, 1 part of antioxidant 245, 0.5 part of auxiliary antioxidant GW508, 1.3 parts of light stabilizer 770, 7 parts of polyester fiber, silica gel 4 parts, 4 parts of vegetable oil, 1.2 parts of butyl titanate, 3 parts of sorbic acid, 8 parts of hydroxypropyl starch, 3 parts of hydroxypropyl methylcellulose.

[0037] The preparation method of the high temperature and light aging resistance degradable PE film described above, the steps are as follows:

[0038] Step 1: Add PE, polyester fiber, silica gel powder, butyl titanate and hydroxypropyl methylcellulose into the reaction kettle, and stir for 40 minutes at a temperature of 90°C and a vacuum of 0.05MPa. , the stirring speed is 90 rev / min, and mixture 1 is obtained;

[0039] Step 2, adding the remaining components to the mixture 1 obtained in the step 1, stirring and mixing evenly, specifically stirring a...

PUM

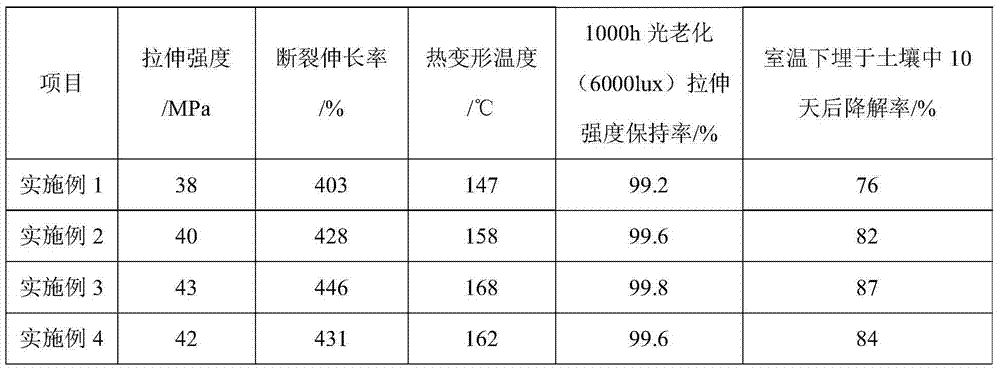

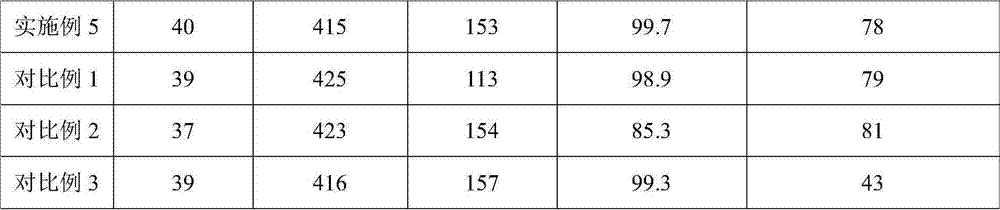

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com