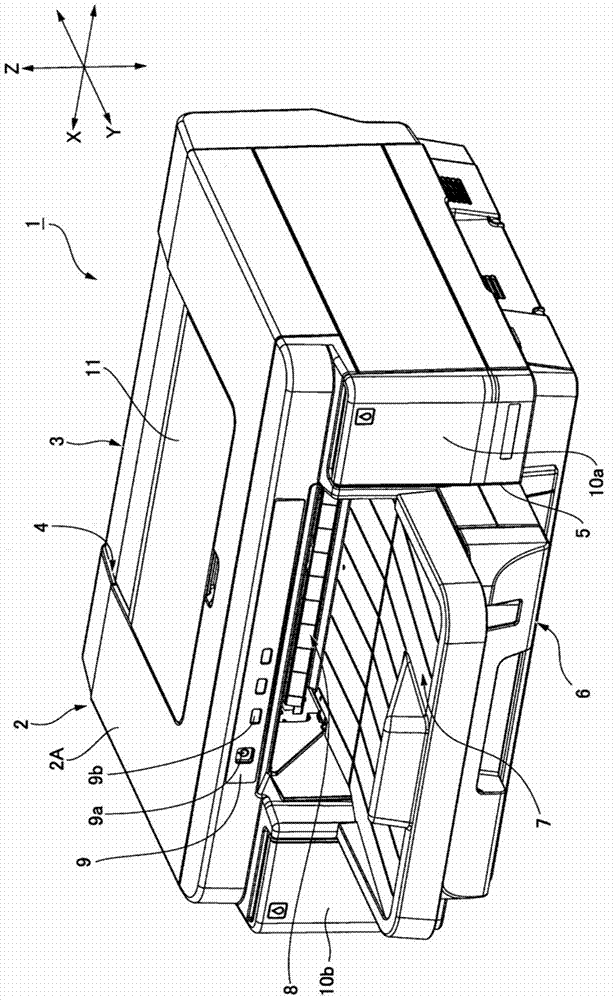

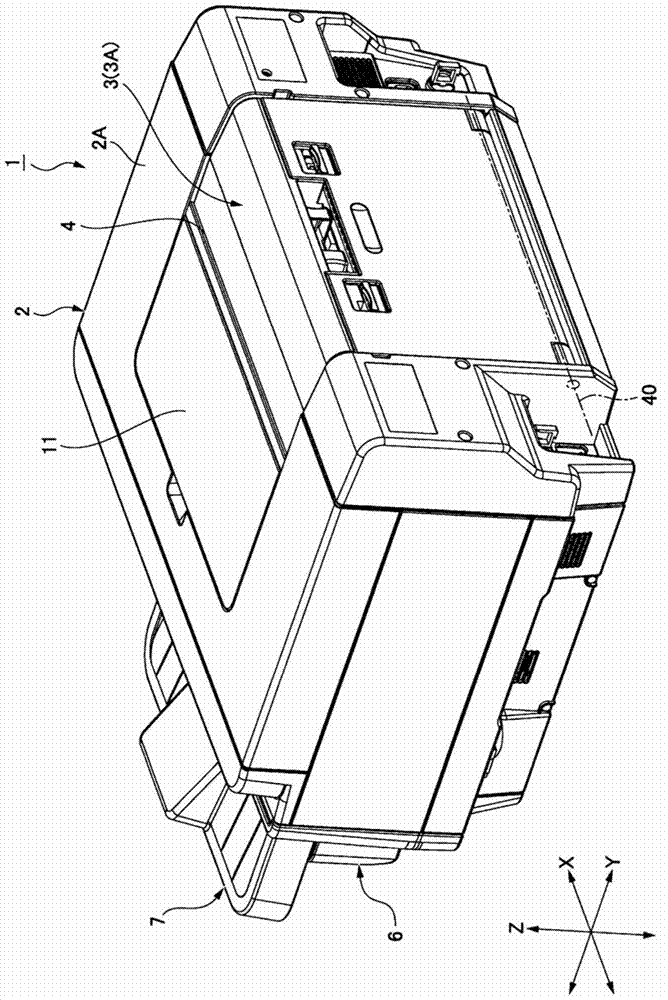

Printer and control method therefor

一种控制方法、打印机的技术,应用在打字机、打印装置、印刷等方向,能够解决未进行考虑等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

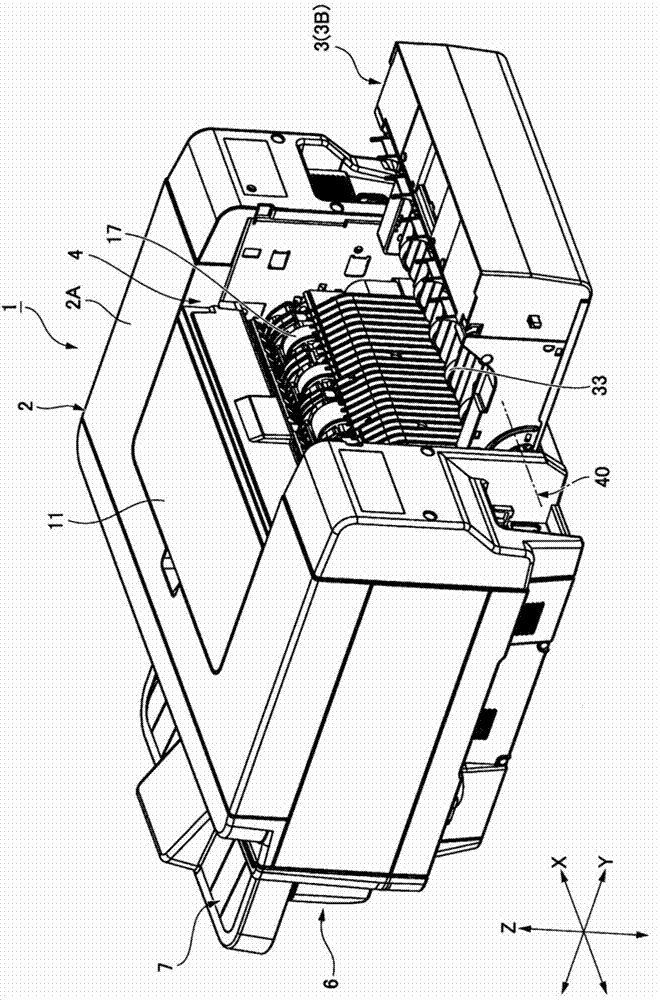

no. 1 Embodiment approach

[0113] (Paper Feed Control During Duplex Printing)

[0114] Here, paper conveyance control during double-sided printing according to the first embodiment will be described.

[0115] Figure 7 (a) is a flow chart of paper conveyance control during duplex printing, Figure 7 (b) is a flowchart showing details of conveyance control at the time of return and return. in addition, Figure 8 It is an explanatory diagram schematically showing the state of the paper P under conveyance control during double-sided printing, Figure 8 (a) show Figure 7 The state of the paper P in step S1 of (a), Figure 8 (b) show Figure 7 The state of the paper P in step S2 of (a), Figure 8 (c) show Figure 7 The state of the paper P in step S3 of (a).

[0116] First, refer to Figure 7 (a), Figure 8 (a) to (c) briefly describe paper conveyance control during double-sided printing. When the print data is print data for double-sided printing, the control unit of the printer 1 performs a pr...

no. 2 Embodiment approach

[0135] (Paper Feed Control During Duplex Printing)

[0136] Here, paper conveyance control during double-sided printing according to the second embodiment will be described. The paper conveyance control during double-sided printing according to the second embodiment is paper conveyance control that recognizes the trailing end position of the conveyed paper P and controls conveyance of the paper.

[0137] First, if Figure 7 (a), Figure 8 As shown in (a) to (c), when the print data is for double-sided printing, the control unit of the printer 1 performs printing processing on the front surface of the paper P in step S1 (first step). That is, in step S1, the paper P is sent from the paper supply path 12 to the main body side conveyance path 13 via the common path 30 by the paper feed roller 15, the retard roller 16, and the conveyance roller 17 (see Figure 8 (a)). Then, the pair of paper feed rollers 21 etc. are driven to convey the paper P in the first direction FF toward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com