Granular cationic dye adsorbent and preparation method thereof

A technology of cationic dyes and adsorbents, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. The effect of degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

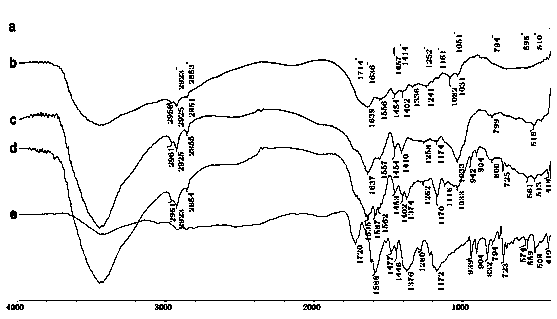

Image

Examples

Embodiment 1

[0036] Under stirring, 1.5g gelatin, 2.0g acrylamide, 2.0g acrylic acid, 0.05g trimethylolpropane triacrylate and 0.05g N,N' -Methylenebisacrylamide was dissolved in 50 mL of water; after each component was dissolved, 1.0 g of attapulgite was added to the mixture and dispersed evenly; 0.2 g of initiator potassium persulfate was added, and reacted at 90°C for 3 h; adjusted The pH of the mixed solution is 6-7, and after being dehydrated with industrial ethanol, it is dried at room temperature to obtain granular adsorption materials. The adsorption material has a removal rate of 75% for malachite green and an adsorption capacity of 1510 mg / g, and can selectively adsorb malachite green in a mixed solution of malachite green and orange II.

Embodiment 2

[0038] Dissolve 0.5 g of gelatin, 5.0 g of itaconic acid, 0.2 g of acrylic acid, 1.0 g of methyl methacrylate, and 0.3 g of ethylene glycol dimethacrylate in 50 mL of water while stirring; Add 2.0g montmorillonite to the mixed solution and disperse evenly; add 0.2g initiator ammonium persulfate, N,N,N'N'-Tetramethylethylenediamine 0.5g, react at 20°C for 3h; adjust the pH of the mixture to 6~7, dehydrate it with industrial ethanol, and dry it at room temperature to obtain granular adsorption materials. The adsorption material has a removal rate of 81% for malachite green and an adsorption capacity of 1625 mg / g, and can selectively adsorb malachite green in a mixed solution of malachite green and orange II.

Embodiment 3

[0040] Dissolve 2.0 g of gelatin, 4.0 g of methacrylic acid and 0.3 g of trimethylolpropane trimethacrylate in 50 mL of water under stirring; after the components are dissolved, add 1.0 g of montmorillonite and 1.0g illite and disperse evenly; add 0.5g initiator hydrogen peroxide and 0.1g thiourea, react at 30°C for 3h; adjust the pH of the mixture to 6~7, dehydrate it with industrial ethanol, and dry it at room temperature to obtain granular Adsorbent material. The adsorption material has a removal rate of 91% for malachite green and an adsorption capacity of 1839 mg / g, and can selectively adsorb malachite green in a mixed solution of malachite green and orange II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com