Self-supporting type nano-porous nickel/nickel oxide combined electrode plate and preparation method thereof

A nanoporous nickel and composite electrode technology, which is applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology, etc., can solve the problems of easy falling off of electroactive materials, poor dispersion of nickel oxide, and preparation of electrode sheets separately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

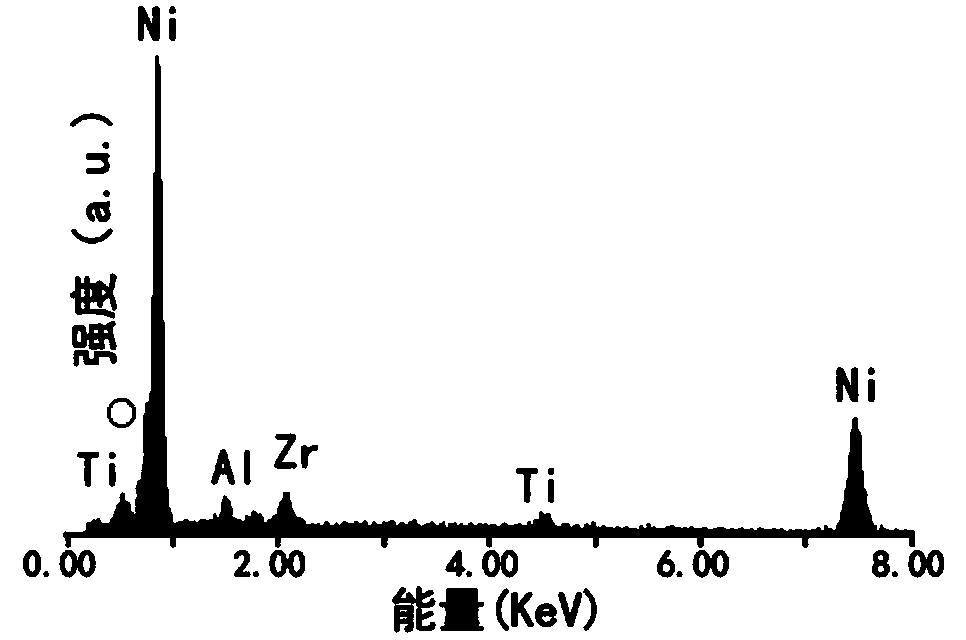

[0038] The first step, the selection of alloy components and alloy preparation

[0039] According to the alloy composition point is Ni 45 (Ti 0.35 Zr 0.45 al 0.2 ) 55 Select metal materials, the raw materials are respectively 99.9% pure nickel, 99.9% pure titanium, 99.9% pure zirconium, and 99.9% pure aluminum by mass percent, and 10 g of this alloy is smelted by a known electric arc furnace as a precursor thin film The smelting conditions of the raw material are as follows: the smelting current is gradually increased from 30A to 110A, the smelting is repeated 3 times, each time for 40 seconds, and the furnace is cooled to obtain a Ni-Ti-Zr-Al alloy ingot;

[0040] The second step is to prepare Ni-Ti-Zr-Al precursor amorphous alloy thin strips

[0041] Remove the surface oxide skin from the Ni-Ti-Zr-Al alloy ingot prepared in the first step, and prepare Ni-Ti-Zr-Al amorphous alloy thin strips using vacuum stripping equipment. The stripping conditions are: at 9×10 -4 Heat...

Embodiment 2

[0051] The first step, the selection of alloy components and alloy preparation

[0052] The selected alloy composition point is Ni 43 (Ti 0.35 Zr 0.45 al 0.2 ) 57 , and smelting 10g of this alloy through a known electric arc furnace as a raw material for preparing precursor strips, the smelting conditions are: the smelting current is gradually increased from 30A to 110A, and the smelting is repeated 3 times, each time for 40 seconds, and the furnace is cooled to obtain Ni-Ti-Zr-Al alloy ingot;

[0053] The second step is to prepare Ni-Ti-Zr-Al precursor amorphous alloy thin strips

[0054] Remove the surface oxide skin from the Ni-Ti-Zr-Al alloy ingot prepared in the first step, and prepare Ni-Ti-Zr-Al amorphous alloy thin strips using vacuum stripping equipment. The stripping conditions are: at 9×10 -4 Heating the molten alloy ingot under a Pa vacuum, and then blow-casting the molten Ni-Ti-Zr-Al alloy to form an amorphous alloy strip, the pressure required for blow-cast...

Embodiment 3

[0061] The first step, the selection of alloy components and alloy preparation

[0062] The selected alloy composition point is Ni 40 (Ti 0.35 Zr 0.45 al 0.2 ) 60 , and smelting 10g of this alloy through a known electric arc furnace as a raw material for preparing precursor strips, the smelting conditions are: the smelting current is gradually increased from 30A to 110A, and the smelting is repeated 3 times, each time for 40 seconds, and the furnace is cooled to obtain Ni-Ti-Zr-Al alloy ingot;

[0063] The second step is to prepare Ni-Ti-Zr-Al amorphous alloy thin strips

[0064] Remove the surface oxide skin from the Ni-Ti-Zr-Al alloy ingot prepared in the first step, and prepare Ni-Ti-Zr-Al amorphous alloy thin strips using vacuum stripping equipment. The stripping conditions are: at 9×10 -4 Heating and melting the alloy raw material under Pa vacuum degree, and then blow-casting the molten Ni-Ti-Zr-Al alloy to form an amorphous alloy strip, the pressure required for bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com