A multifunctional power board test production line

A power board and production line technology, which is applied in the direction of electronic circuit testing, measuring device casing, sorting, etc., can solve PCBA unqualified problems, achieve stable quality, improve work efficiency and automation, and solve the effects of PCBA unqualified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

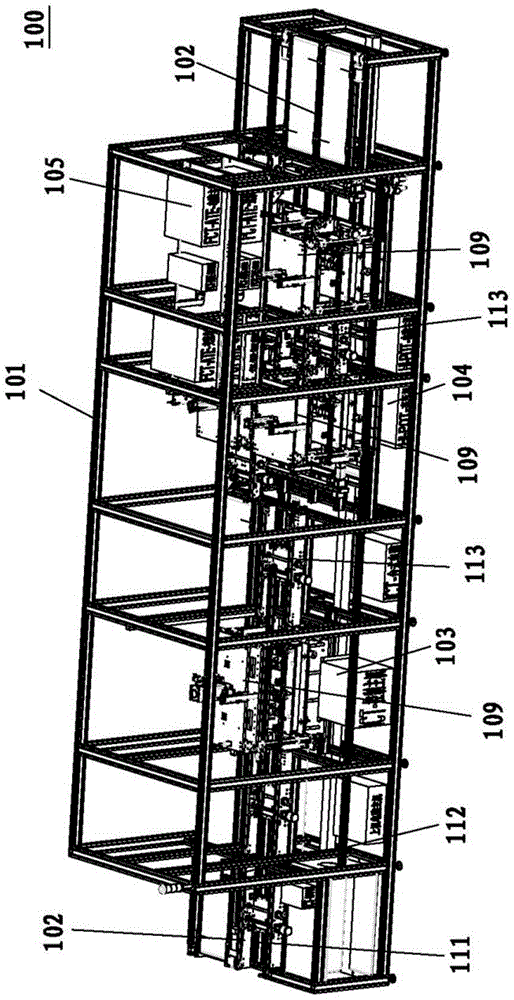

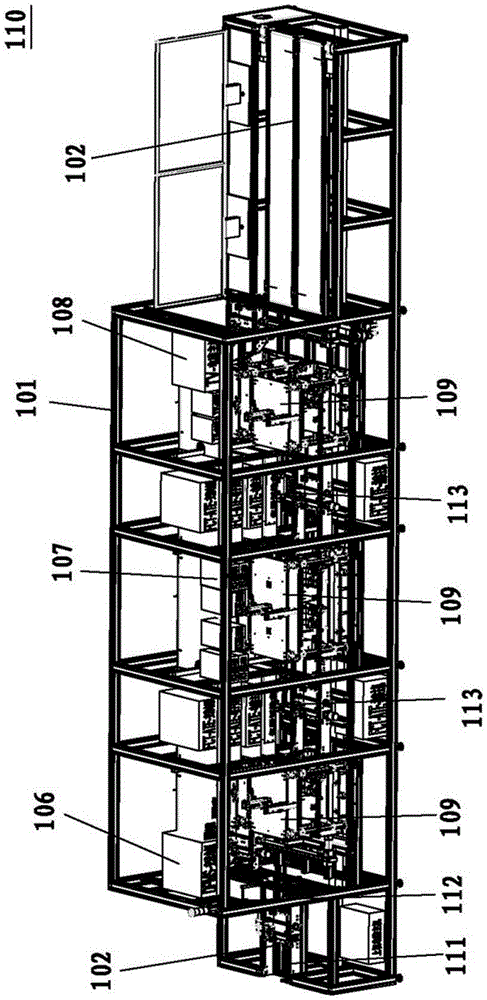

[0025] Embodiment 1, reference figure 1 and figure 2 , a multifunctional power board testing production line, comprising a first testing device 100 and a second testing device 110, the power board flows through the first testing device 100 and then enters the second testing device 110, the first testing device 100 and the second testing device 110 The devices 110 all include a frame 101, a conveyor belt 102 across the frame 101, and a test fixture 109 arranged on the frame 101; the first test device 100 also includes an ICT test mechanism 103, a Hi-pot test mechanism 104 and an FCT The testing mechanism 105, the ICT testing mechanism 103, the Hi-pot testing mechanism 104 and the FCT testing mechanism 105 are successively arranged on the frame 101 of the first testing device 100; the second testing device 110 also includes a DPMS testing mechanism 106, an ATE testing mechanism 107 and The TV test mechanism 108 , the DPMS test mechanism 106 , the ATE test mechanism 107 and the...

Embodiment 2

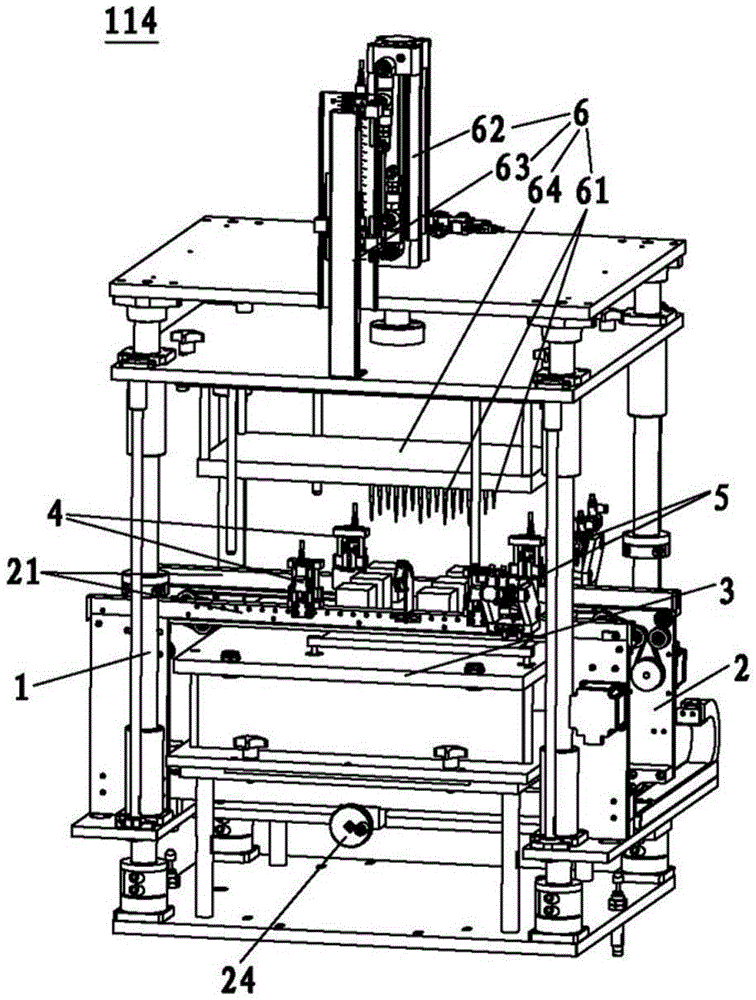

[0030] Embodiment 2, refer to Figure 4 and Figure 8 , the difference from Embodiment 1 is that the test fixture 109 of this embodiment is set as a double power supply board test fixture 115, and the double power supply board test fixture 115 is provided with a synchronous scraper mechanism 7, and a synchronous scraper mechanism 7 Including a synchronous frame 71, a synchronous cylinder 72, a synchronous motor 73, a synchronous belt 74, a synchronous wheel 75 and an origin sensor 76, the synchronous frame 71 includes a synchronous track 77, a support portion 78 arranged on the top of the synchronous track 77 and fixed on the support portion 78 The top plate 79, the synchronous cylinder 72 is arranged on the top plate 79, the synchronous motor 73 is arranged on the support portion 78, the synchronous belt 74, the synchronous wheel 75 and the origin sensor 76 are all arranged on the synchronous track 77. The synchronous track 77 is provided with a first locking position 771 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com