Turning measurement device and method of swing degree of upper operating oil pipe of hydraulic blade all-adjustable water pump

A technology for operating oil pipes and measuring devices, applied in the directions of measuring devices, components of pumping devices for elastic fluids, pumps, etc., can solve the measurement error of the swing of the upper operating oil pipe, the copper sleeve is burnt and damaged, and cannot be adjusted. Blade and other problems, to ensure safety, reduce sealing gap, save operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

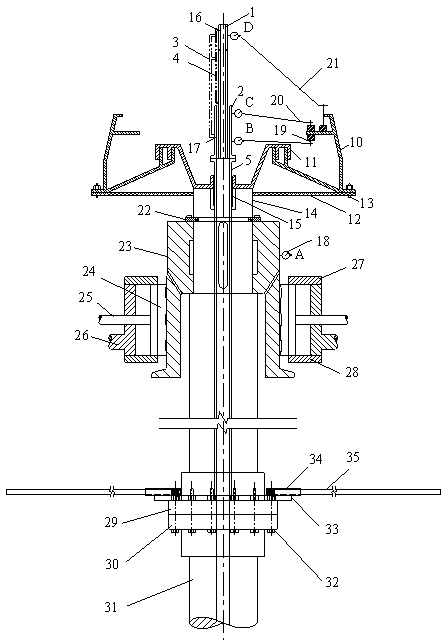

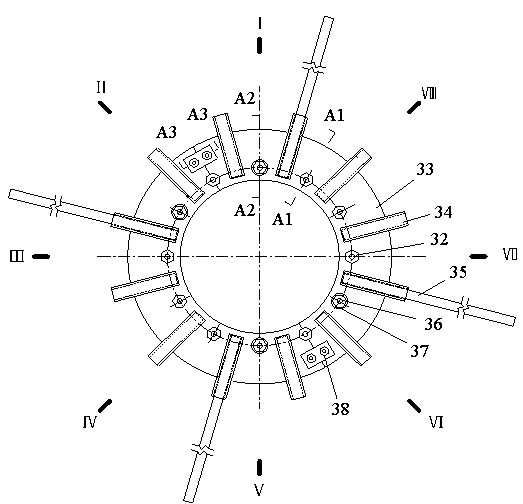

[0026] Such as figure 2 , 3 As shown, to manufacture the special turning tool for the motor shaft coupling 29, first of all, it is necessary to master the flange diameters of the unit motor shaft coupling 29 and the water pump shaft coupling 30, and to connect the motor shaft coupling 29 and the water pump shaft. The distribution circle diameter of the refined bolt 32-1 of the coupling 30, the diameter of the refined bolt 32-1 and the diameter of the refined bolt fixing nut 32-2. There are generally 12 refined bolts 32-1. Contrast the diameter of the motor shaft coupling 29 and the diameter of the motor shaft 14, make two identical half-type annular plates 33 with common steel plates, the inner diameter of the half-type annular plates 33 is slightly larger than the motor shaft 14, and the outer diameter is larger than the motor shaft The diameter of the flange of coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com