Nail embedded floor heating floor

A floor and floor heating technology, applied in the field of studded floor heating, can solve problems such as environmental protection, poor human contact feeling and aesthetics, and floor warping and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The floor heating floor with studs of the present invention will be described in detail below in conjunction with the accompanying drawings.

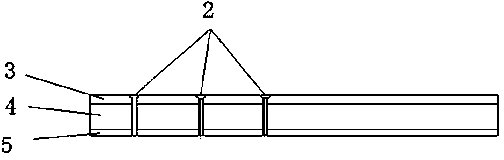

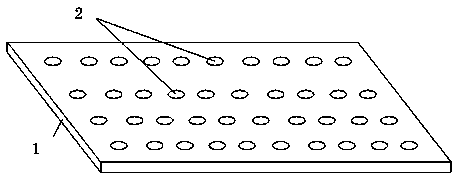

[0016] Such as figure 1 , 2 As shown, a floor heating floor with studs includes a body 1 and metal heat-conducting nails 2; a group of metal heat-conducting nails are evenly inlaid on the body and run through the entire body from top to bottom. From top to bottom, the main body is the floor surface layer 3, the floor core layer 4, and the floor substrate 5; the floor surface layer, the floor core layer and the floor substrate are made of solid wood or plastic. The floor surface and the floor substrate are respectively glued to the upper surface and the lower surface of the floor core.

[0017] Metal heat conducting nails can be made of aluminum, copper, stainless steel, various alloys and other materials with good thermal conductivity. Circular, elliptical, polygonal or arbitrary shapes can be used.

[0018] The upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com