Low-carbon aluminium killed steel with excellent stamping properties and production method of low-carbon aluminium killed steel

A technology of low-carbon aluminum-killed steel and production method, which is applied to low-carbon aluminum-killed steel with excellent stamping performance and its production field, and can solve the problems of poor coating adhesion, poor stamping performance, and low plastic strain ratio, etc. Achieve the effects of reducing strength, improving plasticity, and excellent stamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

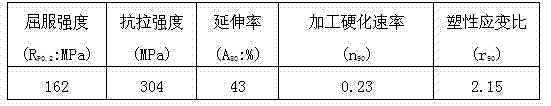

Embodiment 1

[0015] Embodiment 1: The low-carbon aluminum-killed steel with excellent stamping performance is produced by the following specific process.

[0016] The production process of the low-carbon aluminum-killed steel is: converter steelmaking→RH refining→continuous casting hot rolling→cold rolling→annealing. In the traditional design, due to the low content of Si in the converter blowing finished product, there will be no deterioration in the formability of the finished product. The content of Si in this steel is relatively high. Therefore, RH refining is used and calcium-containing ferrosilicon is added to RH to realize the alloying of silicon and the denaturation treatment of inclusions, that is, calcium treatment, so as to improve castability and stabilize the production process; And the vacuum treatment of RH refining can achieve low carbon content (the finished products are all below 0.010%).

[0017] The thickness of the continuous casting slab is 150mm, the composition (wt...

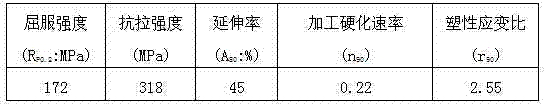

Embodiment 2

[0021] Example 2: The low-carbon aluminum-killed steel with excellent stamping performance is produced by the following specific process.

[0022] The thickness of the continuous casting slab is 150mm, and the composition is: C 0.0053%, Mn 0.09%, S 0.008%, P 0.018%, Si 0.09%, N 30ppm, Als 0.060%, Ca 9ppm, and the balance is Fe and unavoidable impurities. Hot rolling process: the final rolling temperature is 910°C, the hot rolling reduction is 98%, and the coiling temperature is 590°C. The reduction in the cold rolling process was 75%. Bell annealing process: the heating rate is 80°C / hour, the mask annealing temperature is 630 / 690°C, and the holding time is 6 hours.

[0023] After testing, the properties of the low-carbon aluminum-killed steel obtained in this embodiment are shown in Table 2.

[0024] Table 2: Properties of the low-carbon aluminum-killed steel obtained in Example 2

[0025]

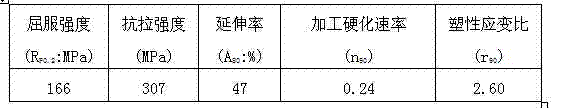

Embodiment 3

[0026] Embodiment 3: The low-carbon aluminum-killed steel with excellent stamping performance is produced by the following specific process.

[0027] The thickness of the continuous casting slab is 150mm, and the composition is: C 0.0042%, Mn 0.11%, S 0.007%, P 0.015%, Si 0.18%, N 25ppm, Als 0.030%, Ca 12ppm, and the balance is Fe and unavoidable impurities. Hot rolling process: the final rolling temperature is 920°C, the hot rolling reduction is 97%, and the coiling temperature is 620°C. The reduction in the cold rolling process was 80%. Bell annealing process: the heating rate is 70°C / hour, the mask annealing temperature is 670 / 720°C, and the holding time is 9 hours.

[0028] After testing, the properties of the low-carbon aluminum-killed steel obtained in this embodiment are shown in Table 3.

[0029] Table 3: Properties of low-carbon aluminum-killed steel obtained in Example 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com