Trichoderma reesei strain and application thereof

A technology of Trichoderma reesei and strains, applied in the field of microorganisms, can solve the problems of high inducer cost, long production cycle, low cellulase enzyme activity, etc., and achieve the effect of strong protein secretion capacity and strong production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Utilization of the starting strain Rut C30 for mutagenesis to obtain the high-yield strain DES-15

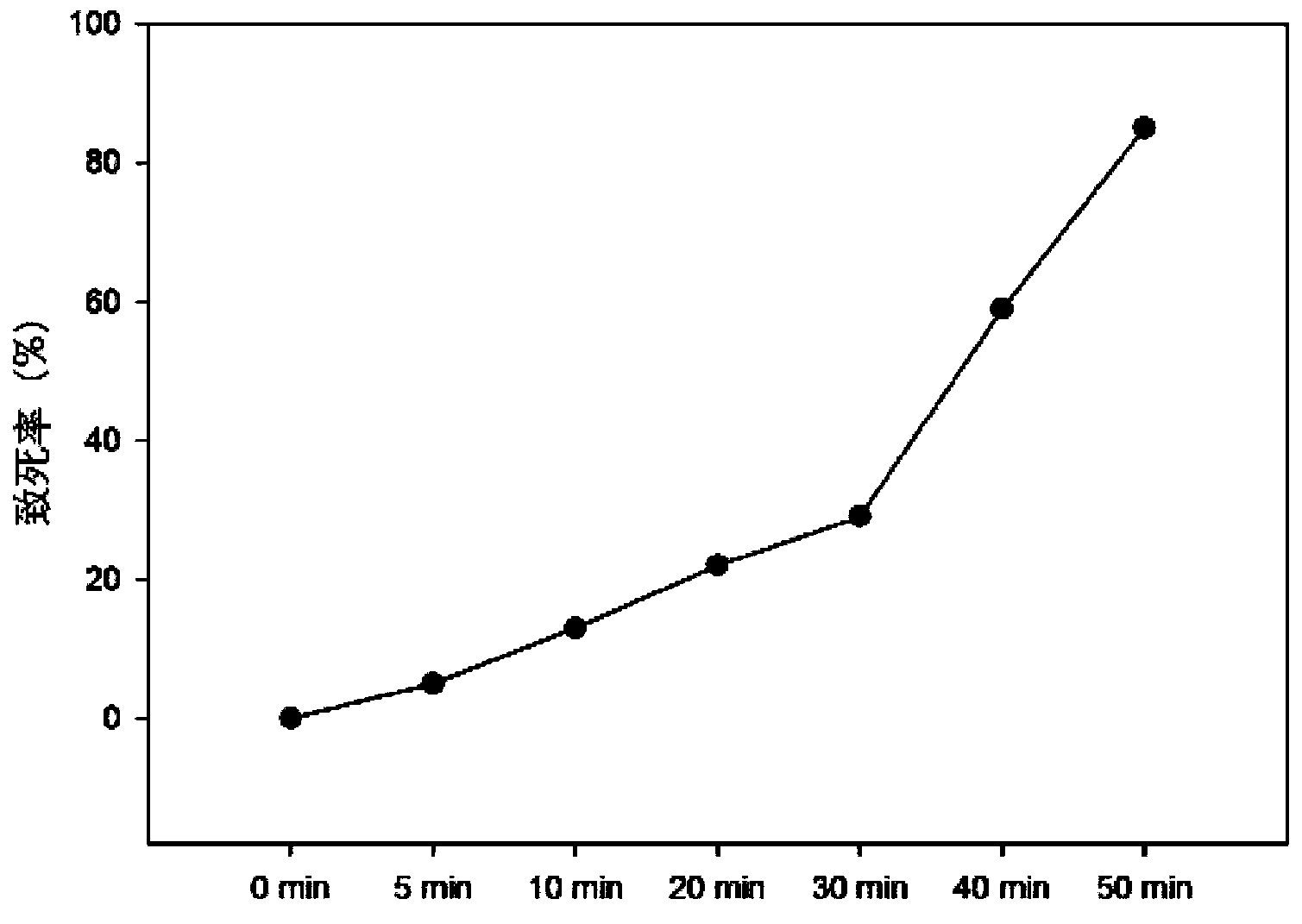

[0019] The high-yield bacterial strain DES-15 of the present invention is obtained by diethyl sulfate mutagenesis, carries out 6 groups of mutagenesis experiments, and the reaction times of 6 groups of mutagenesis experiments are respectively 5min, 10min, 20min, 30min, 40min and 50min, All other conditions are the same.

[0020] The specific process of the mutagenesis experiment is as follows: the starting strain Rut C30 is placed on a PDA plate and cultured at 30° C. for 5-7 days until the spores cover the plate. Wash the spores with phosphate buffer (pH7.0), filter through three layers of lens paper to obtain the spore suspension, and dilute the spore suspension to 10 6 pieces / ml. Add 0.2ml diethyl sulfate (DES for short) to the 10ml diluted spore suspension, and react for a certain period of time (rotating speed is 100rpm) in a shaker at room temperature. A...

Embodiment 2

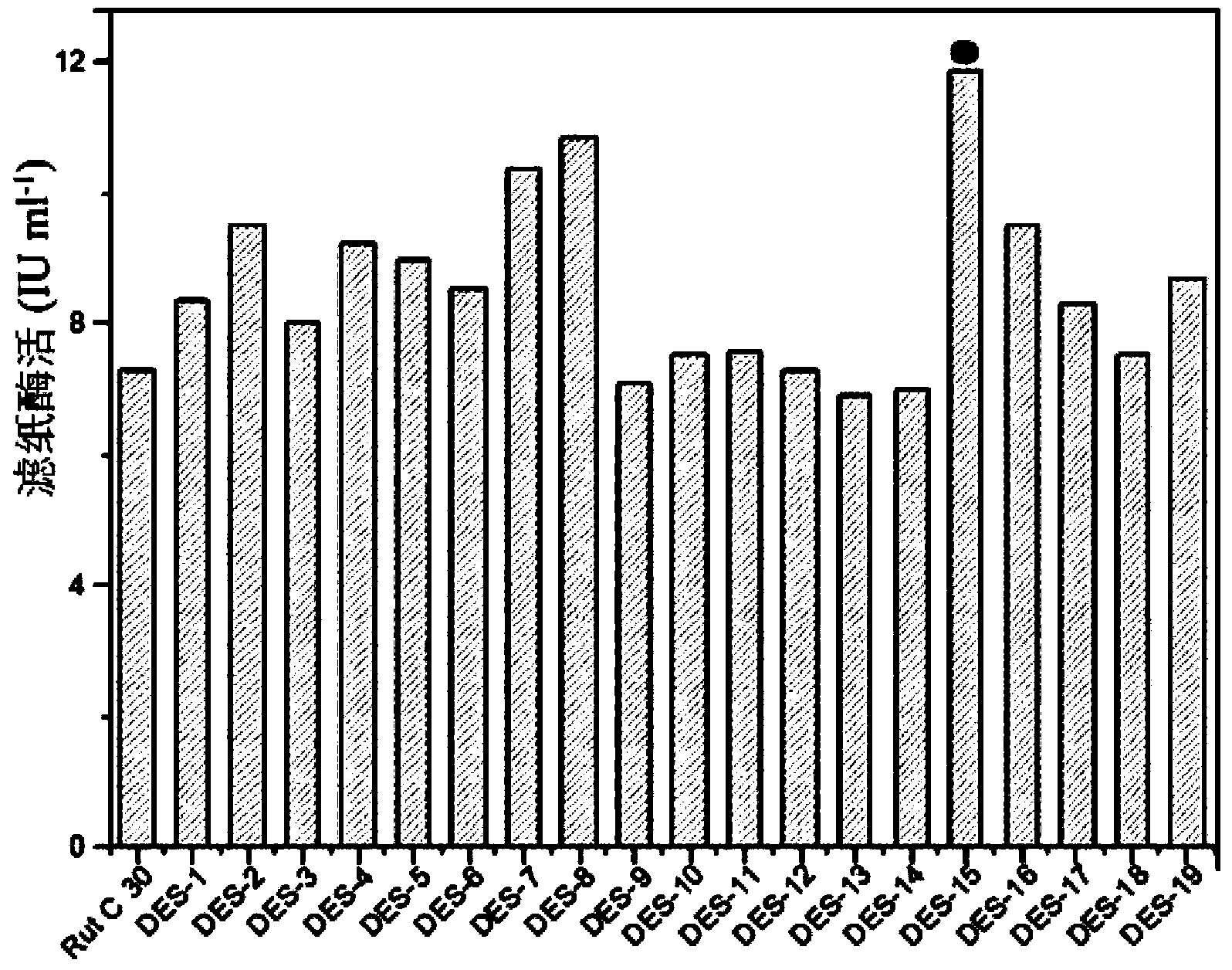

[0024] The screening of embodiment two high-yielding bacterial strain DES-15

[0025] 60 bacterial strains were randomly selected from the plates (group 6 mutagenesis experiments) from which the colonies grew, and were connected to new PDA plates for purification and culture. The 60 strains selected at random were inserted into the fermentation medium and cultured for 6 days, and then the enzyme activity of the filter paper was measured. The fermentation conditions were: 26°C, 170rpm, initial pH 4.5. The components of the fermentation medium are: microcrystalline cellulose 33g / L, corn steep liquor dry powder 17g / L, ammonium sulfate 5g / L, calcium carbonate 2.5g / L, potassium dihydrogen phosphate 6g / L, magnesium sulfate 1g / L. The obtained fermentation broth was centrifuged at 4°C, and the supernatant was collected for filter paper enzyme activity assay. figure 2 The leftmost item in the table indicates the filter paper enzyme activity of the starting strain Rut C30, and also s...

Embodiment 4

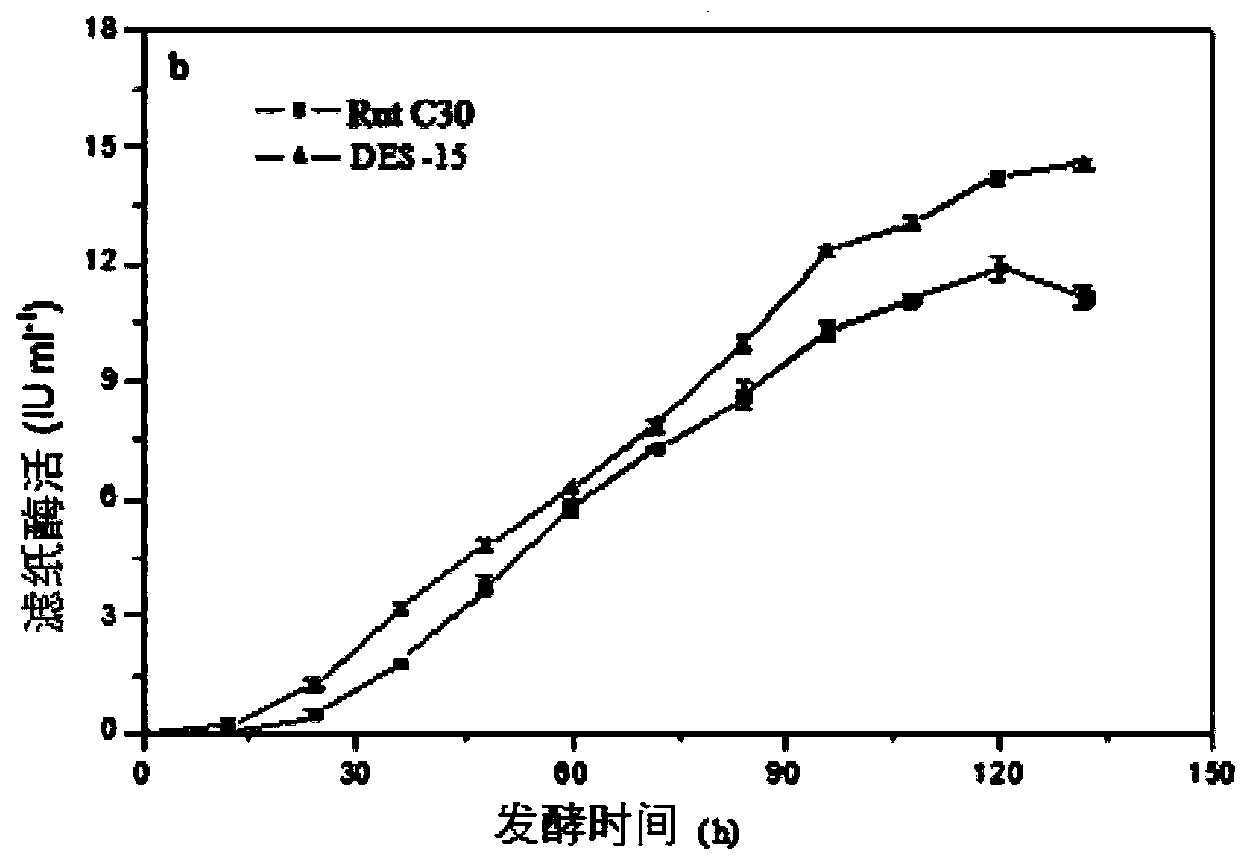

[0030] The starting strain Rut C30 and the high-yielding strain DES-15 were used to carry out the following experiments, and the experimental conditions of the two strains were completely consistent. During the fermentation process, the components of the seed medium and the fermentation medium were consistent with those in Example 3. During the fermentation process, the pH value in the fermenter was controlled to be 4.0, and other conditions were the same as in Example 3. Experiments showed that during the whole fermentation process, the filter paper enzyme activity and protein content of the high-yielding strain DES-15 were higher than those of the starting strain Rut C30, and the highest filter paper enzyme activity of both appeared at 124h. Compare the highest value of enzyme activity and protein concentration of the high-yield strain with the highest value of enzyme activity and protein concentration of the starting strain Rut C30, and calculate the increase rate of filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com