Continuous casting system and process producing large-specification elliptical billets

A technology for large-scale production and continuous casting process, which is applied in the field of continuous casting process, continuous casting system and continuous casting process. Surface quality, crack prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

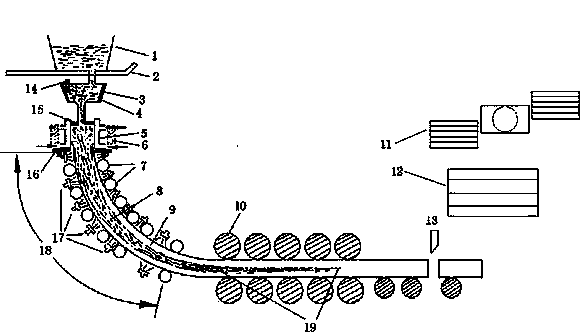

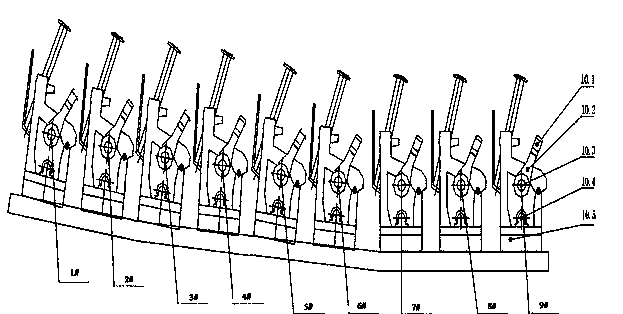

[0034] Such as figure 1 As shown, in order to facilitate the transfer of molten steel, the continuous casting system for producing large-sized elliptical billets in this embodiment is installed in cooperation with the ladle turret 2, which specifically includes: a tundish 3 arranged in sequence: used to receive the steel ladle 1 The injected molten steel is equipped with an induction heating device 4 for heating the molten steel, and a continuous temperature measuring device 14 matched with the induction heating device 4 is arranged in the tundish 3; the crystallizer 5: used to condense the molten steel into a For the elliptical billet, an electromagnetic stirring device 6 for stirring molten steel is provided in the crystallizer 5, and a mold vibrating device 16 is provided below the crystallizer 5 to drive the elliptical billet to be dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com