Breeding ewe complete pellet feed and preparation method thereof

A pellet feed and breeding ewe technology, applied in animal feed, animal feed, applications, etc., can solve problems such as inability to ensure uniformity of feed mixing, coarse feed supply and storage problems, and prominent feed safety problems, so as to ensure normal rumen Physiological functions, huge market demand and benefits, and the effect of improving digestion and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

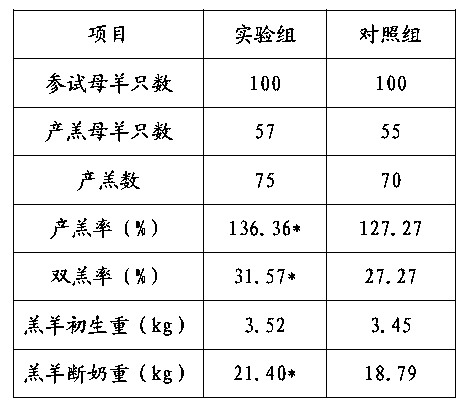

Examples

Embodiment 1

[0023] The full price pellet feed for breeding ewes of the present invention comprises the following components in parts by weight: 15 parts of corn, 5 parts of wheat bran, 5 parts of dry distiller's grains, 2 parts of barley sprout root, 3 parts of corn distiller's grains, and 8 parts of alfalfa powder 15 parts of soybean hulls, 6 parts of peanut shells, 2 parts of apple pomace, 5 parts of bran, 0.1 parts of brewer's yeast culture, 0.4 parts of calcium powder, 0.4 parts of calcium hydrogen phosphate, 0.2 parts of table salt, 0.5 parts of baking soda, sweet 0.1 part of flavoring agent, 0.2 part of trace element additive, 0.2 part of multivitamin, 0.1 part of rumen-passed methionine and 0.2 part of ammoniated corn stalk.

[0024] The trace element additive is composed of the following components in parts by weight: 1 part of copper sulfate pentahydrate, 8 parts of ferrous sulfate monohydrate, 9 parts of zinc sulfate monohydrate, 8 parts of manganese sulfate monohydrate, 8 parts ...

Embodiment 2

[0028] The full-price pellet feed for ewes in this embodiment comprises the following components in parts by weight: 20 parts of corn, 8 parts of wheat bran, 8 parts of dry distiller's grains, 3 parts of barley sprout root, 6 parts of corn distiller's grains, alfalfa grass powder 12 parts, 20 parts of soybean hulls, 10 parts of peanut shells, 4 parts of apple pomace, 8 parts of bran, 0.2 parts of brewer's yeast culture, 1 part of calcium powder, 0.9 parts of calcium hydrogen phosphate, 0.4 parts of table salt, 0.9 parts of baking soda, 0.2 part of sweetener, 0.4 part of trace element additive, 0.4 part of multivitamin, 0.3 part of rumen-passed methionine and 0.3 part of ammoniated corn stalk.

[0029] The trace element additive comprises the following components in parts by weight: 3 parts of copper sulfate pentahydrate, 11 parts of ferrous sulfate monohydrate, 13 parts of zinc sulfate monohydrate, 12 parts of manganese sulfate monohydrate, 10 parts of magnesium sulfate monohyd...

Embodiment 3

[0033] The full-price pellet feed for breeding ewes in this embodiment comprises the following components in parts by weight: 25 parts of corn, 10 parts of wheat bran, 10 parts of dry distiller's grains, 4 parts of barley sprout root, 8 parts of corn distiller's grains, alfalfa powder 15 parts, 25 parts of soybean hulls, 12 parts of peanut shells, 6 parts of apple pomace, 10 parts of bran, 0.3 parts of brewer's yeast culture, 1.5 parts of calcium powder, 1.2 parts of calcium hydrogen phosphate, 0.5 parts of table salt, 1.5 parts of baking soda, 0.3 part of sweetener, 0.5 part of trace element additive, 0.5 part of multivitamin, 0.5 part of rumen-passed methionine and 0.5 part of ammoniated corn stalk.

[0034]The trace element additive comprises the following components in parts by weight: 5 parts of copper sulfate pentahydrate, 15 parts of ferrous sulfate monohydrate, 16 parts of zinc sulfate monohydrate, 14 parts of manganese sulfate monohydrate, 12 parts of magnesium sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com