Storage method for aromatic alkene monomer

A storage method and technology of aromatic olefins, applied in chemical instruments and methods, purification/separation of hydrocarbons, disproportionation separation/purification of halogenated hydrocarbons, etc. Adhesion decline and other problems, to achieve the effect of prolonging the period of maintenance and cleaning tanks, reducing the amount of coating, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

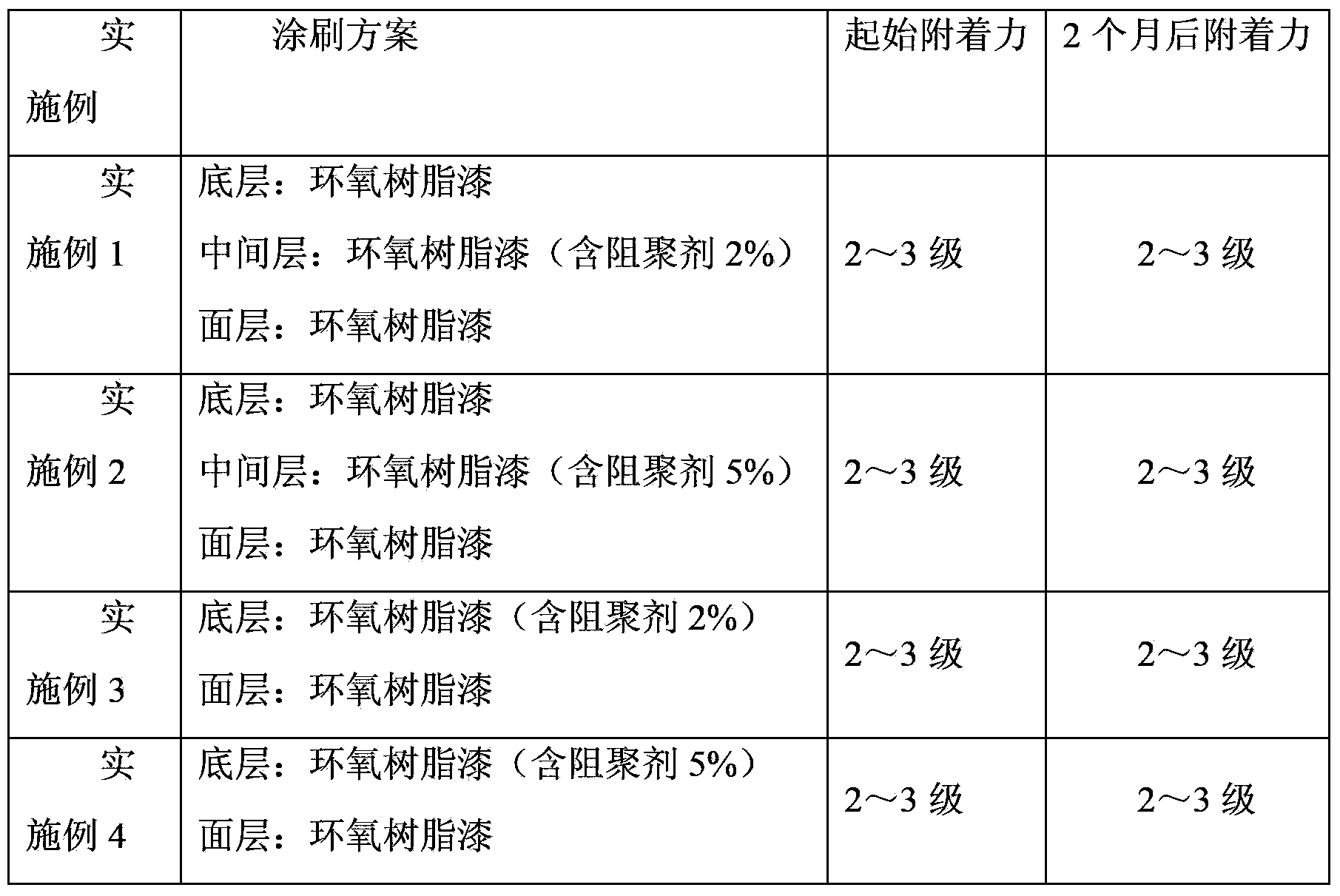

Embodiment 1~4

[0029] Paint epoxy resin paint on the standard tinplate plate (50×100×0.2~0.3mm), the amount of polymerization inhibitor TBC accounts for 2% or 5% of the primer amount (mass, the same below), first grind TBC, Then use a sieve to sieve, the polymerization inhibitor particles are below 200 mesh, add the sieved TBC to the epoxy paint, stir at a temperature of 30°C, add auxiliary materials and mix for 0.5 hours after the material is coated. Brush for later use. Two-layer and three-layer overcoating methods are adopted respectively, wherein the thickness of the bottom layer in Examples 1-2 is about 30 μm, the thickness of the middle layer is about 60 μm, and the surface layer is about 100 μm. The thickness of the bottom layer in Examples 3-4 is about 30 μm, and the thickness of the surface layer is about 110 μm. After the coating was dry, the adhesion was tested, and then the coated panel was placed in a 5L styrene storage tank and soaked at 30°C for 2 months. The results are show...

Embodiment 5~12

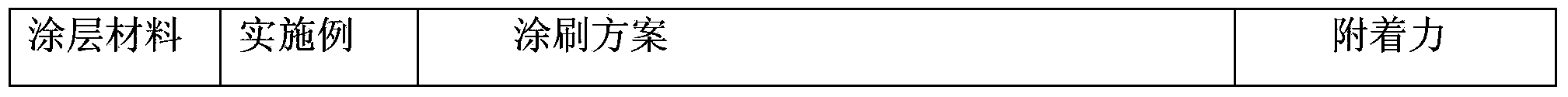

[0034] On the standard tinplate (50×100×0.2~0.3mm), use different coatings, different polymerization inhibitors, and two-layer overcoating methods to paint, and the addition of polymerization inhibitors accounts for 15% of the primer. The mixing temperature of the polymerization agent and the paint is 45°C, and the change of the coating adhesion is shown in Table 2. The thickness of the bottom layer is about 60 μm, and the thickness of the surface layer is about 150 μm.

[0035] Table 2 Variation of adhesion of different coatings

[0036]

[0037]

[0038] It can be seen from Table 2 that no matter what kind of coating, the suitable method of adding the polymerization inhibitor should be directly added to the coating. The finer the polymerization inhibitor particles, the higher the mesh number, and the more uniform it is after mixing with the coating, which is conducive to the improvement of coating adhesion. improve. After the above-mentioned coated boards were soaked...

Embodiment 13~16

[0040] Brush epoxy resin paint on the inner wall of the 5L styrene storage tank tank top, wherein the polymerization inhibitor is a compound of TBC and DNPC, and the total addition accounts for 25% of the primer amount, wherein TBC: DNPC mass ratio is respectively: Example 13 is 2:1, Example 14 is 8:1, Example 15 is 1:3, Example 16 is 1:7, first mix the polymerization inhibitor and then grind and sieve to 200 mesh, then compound The polymerization inhibitor is added to the epoxy paint, stirred at a temperature of 35°C until uniform, and then mixed with auxiliary materials evenly, and the method of two-layer overcoating is used to paint according to different surface thicknesses. Under the storage temperature of 40°C, the styrene condensate was collected regularly, and the content of polymerization inhibitor was analyzed. The results are shown in Table 3.

[0041] Table 3 Changes in the content of polymerization inhibitors in the condensate under different thicknesses of the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com