A conduction cooling stack semiconductor laser packaging structure

A technology of conduction cooling and packaging structure, used in semiconductor lasers, lasers, laser components and other directions, can solve the problems of poor system integration, large packaging structure and other problems, achieve high power output, improve heat dissipation performance, and achieve the effect of power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

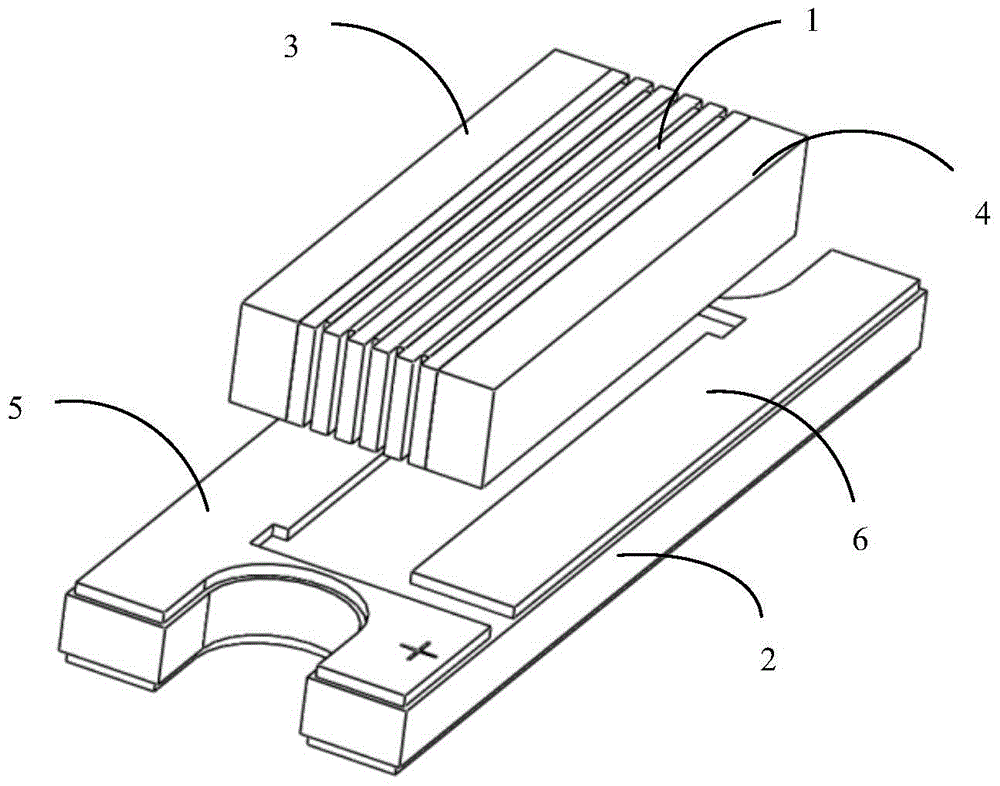

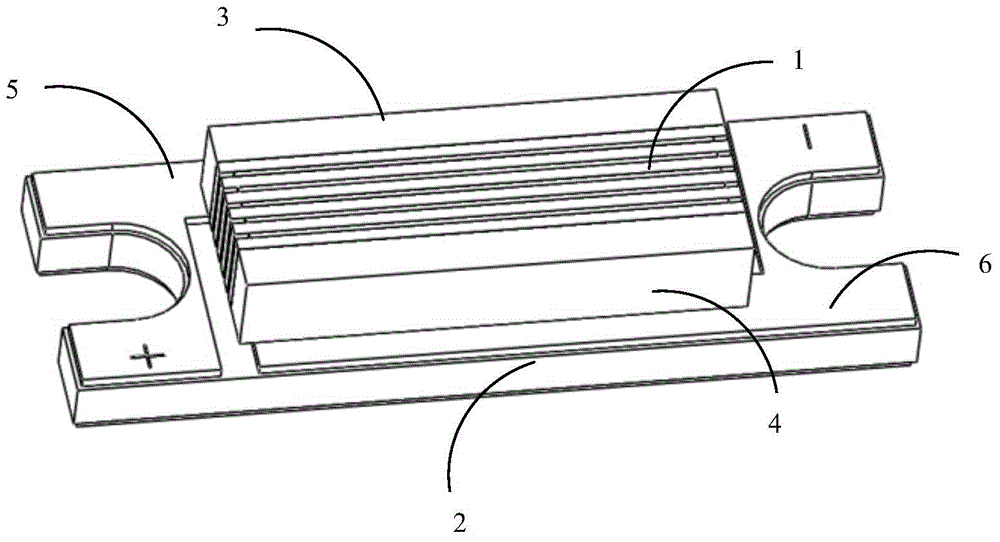

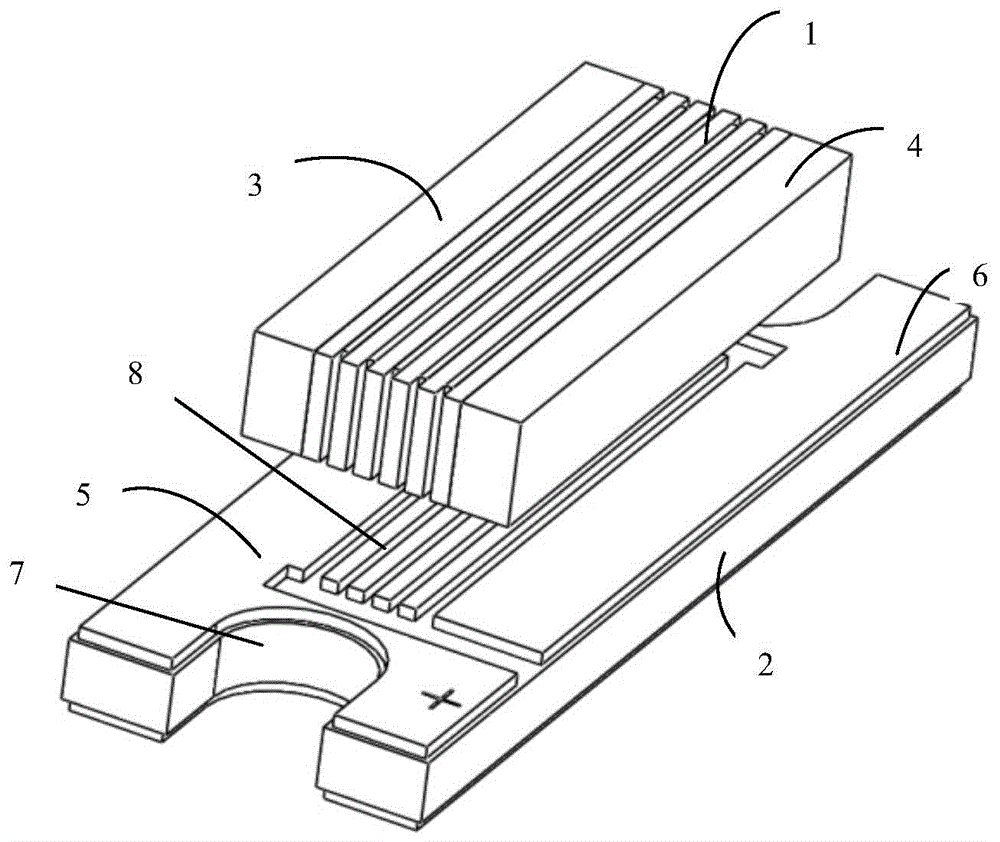

[0036] Such as figure 1 As shown, the conduction cooling stacked semiconductor laser packaging structure of the present invention includes a laser chip group 1 and an insulating heat sink 2, and the laser chip group 1 adopts a plurality of laser chips to form a stacked module, wherein each laser chip has a substrate ; The two end faces of the array module chip stacking direction are bonded and welded with a positive connection block 3 and a negative connection block 4; the surface of the insulating heat sink is provided with two L-shaped conductive sheets that are not in contact with each other in a centrosymmetric manner , respectively as the positive electrode 5 and the negative electrode 6; the bottoms of the positive connection block 3 and the negative connection block 4 are respectively welded and fixed to the long parts of the two L-shaped conductive sheets, and the stacked module 1 corresponds to the two L-shaped The conductive sheet surrounds a rectangular strip area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com