Organic photovoltaic battery and manufacturing method thereof

An organic photovoltaic cell and optical technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of ineffective separation of excitons, inability to fully absorb light, inability to fully absorb excitons, etc., to solve the problem of ineffective separation of excitons , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

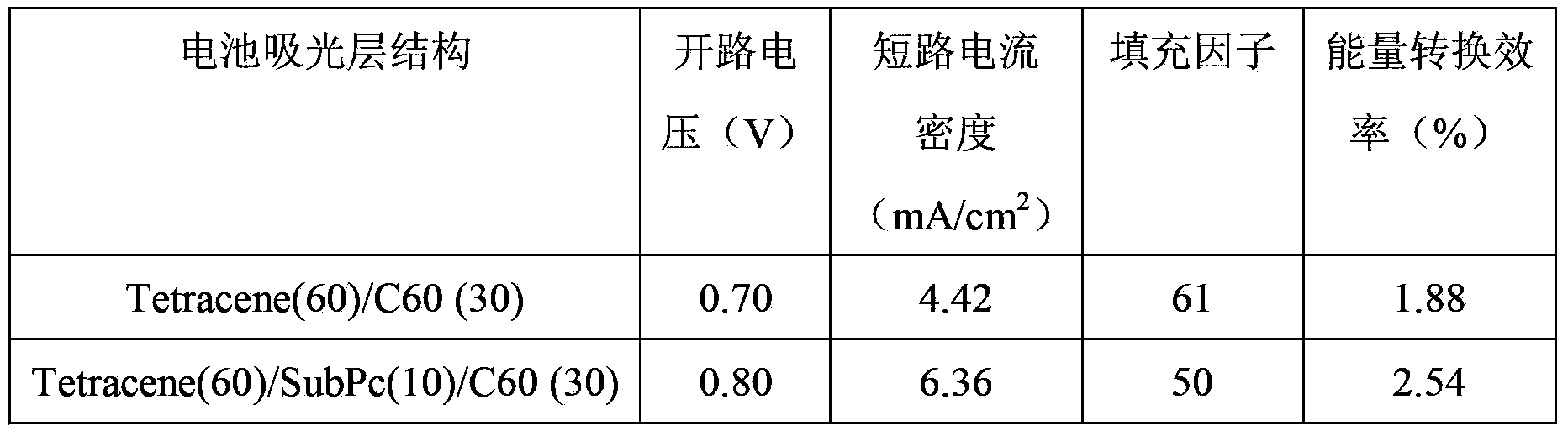

Embodiment 1

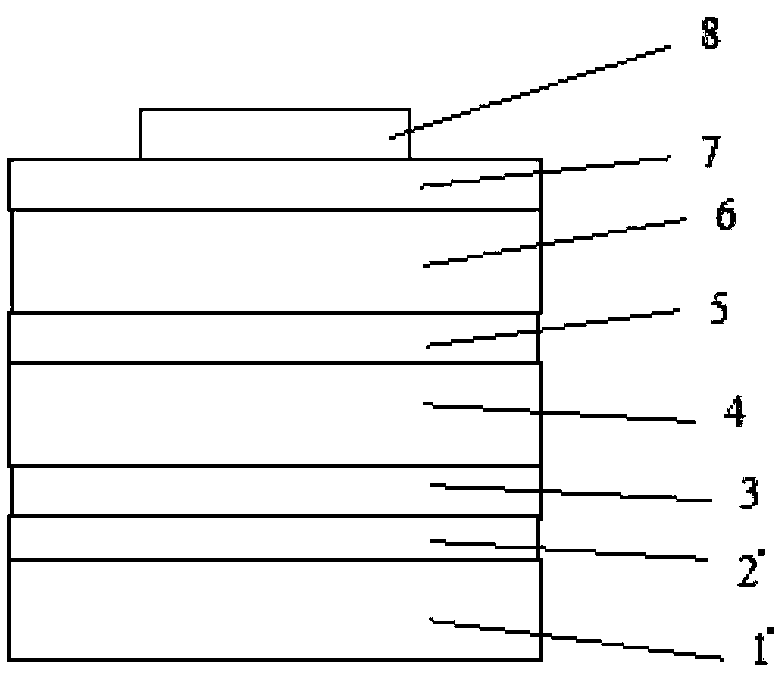

[0032] Such as figure 2 As shown, an organic photovoltaic cell preparation method, the steps are as follows:

[0033] 1) Use the glass (FTO) substrate 1'as the anode 2'of the transparent conductive film of the organic battery, and clean it ultrasonically in deionized water, ethanol and acetone;

[0034] 2) A layer of poly 3,4-ethylenedioxythiophene monomer doped with polystyrene sulfonic acid (PEDOT:PSS), which has a good hole transport material, is prepared by spin coating on the dried anode surface as the anode modification layer 3. The thickness is about 40nm, and it completely covers the surface of the suede electrode, and annealed at 135 degrees for 20 minutes;

[0035] 3) On the surface of the prepared anode modification layer 3, prepare Tetracene as the first donor material 4 by evaporation method, with a thickness of about 60nm;

[0036] 4) On the surface of the prepared first donor material 4, prepare SubPc as the second donor material 5 by evaporation method, the thickness...

Embodiment 2

[0044] A method for preparing the organic photovoltaic cell with the double heterojunction parallel structure, the steps are as follows:

[0045] 1) Use the textured transparent conductive film glass (AZO) substrate as the anode of the organic battery, and clean it ultrasonically in deionized water, ethanol and acetone;

[0046] 2) A layer of polymolybdenum oxide MoO with good hole transport material is prepared by spin coating on the dried anode surface 3 As an anode modification layer, the thickness is about 40nm, and it completely covers the surface of the suede electrode, and it is annealed at 135 degrees for 20 minutes;

[0047] 3) On the surface of the prepared anode modified layer, prepare CuPc as the first donor material by evaporation method, the thickness is about 15nm;

[0048] 4) On the surface of the prepared first donor material, prepare SubPc as the second donor material by evaporation method, the thickness is about 16nm;

[0049] 5) On the surface of the prepared second ...

Embodiment 3

[0056] A method for preparing the organic photovoltaic cell with the double heterojunction parallel structure, the steps are as follows:

[0057] 1) Use the textured transparent conductive film glass (ITO) substrate as the anode of the organic battery, and clean it ultrasonically in deionized water, ethanol and acetone;

[0058] 2) A layer of tungsten oxide WO with a good hole transport material is prepared by spin coating on the dried anode surface 3 As an anode modification layer, the thickness is about 40nm, and it completely covers the surface of the suede electrode, and it is annealed at 135 degrees for 20 minutes;

[0059] 3) On the surface of the prepared anode modification layer, prepare Pentacene as the first donor material by evaporation method, the thickness is about 50nm;

[0060] 4) On the surface of the prepared first donor material, prepare ZnPc as the second donor material by evaporation method, the thickness is about 2nm;

[0061] 5) On the surface of the prepared secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com