Device and method for determining radial permeability of compact rock core

A technology of permeability and core, applied in the field of geological exploration and oil and gas field development, can solve the problems of low accuracy of measurement results, large amount of data collection, high cost of instruments, etc., and achieve the effect of stable test results, convenient data collection, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

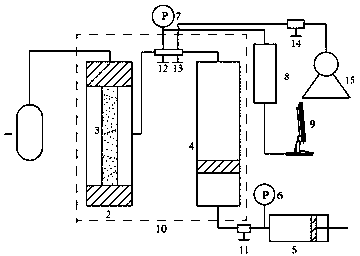

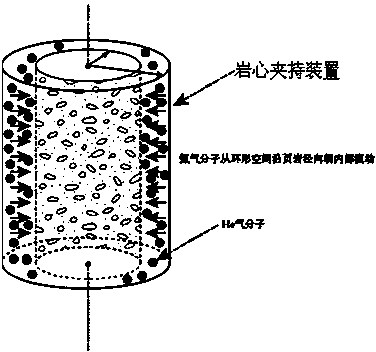

Method used

Image

Examples

example 1

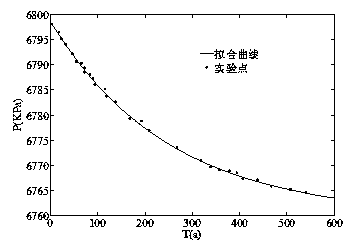

[0095] Example 1: At the beginning of the experiment, the shale was saturated with He gas at a temperature of 30° C., and the pressure value was 5 MPa. Pulse pressure was applied to the core holding device 2 so that the pressure in the closed space of the core holding device 2 was 6.82 MPa. At this time, the gas in the confined space quickly flows into the shale. It should be noted here that the pressure value in the first short period of time is invalid. This is because the gas has not flowed through all the radial range of the shale, so the permeability measured during this period is not the radial value of the entire shale. The average permeability, while its size is changed with the length. The length of this period can be judged by the fitting degree of the model to the experimental data. Fitting the experimental data of the first group according to formula (1), the fitting result is as follows image 3 As shown, one can get a 1 =189m -1 , ξ=38.72KPa, γ=0.004, equilib...

example 2

[0103] Example 2: At the beginning of the experiment, the shale was saturated with He gas at a temperature of 30°C, and the pressure value was 8MPa, while the pressure in the closed space of the core holding device was 9.93MPa. According to the solution process of Example 1, the pressure of the core can be obtained The permeability is 3.62×10 -4 mD, the porosity is 3.49%, the fitting result is as Figure 4 shown.

example 3

[0104] Example 3: At the beginning of the experiment, the shale was saturated with He gas at a temperature of 30° C., and the pressure value was 10 MPa, while the pressure in the closed space of the core holding device was 11.64 MPa. According to the solution process of Example 1, the core can be obtained The permeability is 2.81×10 -4 mD, the porosity is 4.10%, the fitting result is as Figure 5 shown.

[0105] From the test core permeability and porosity results that three groups of examples obtain, it can be seen that the test result stability of the device of the present invention is very good. The average value of the permeability in the radial plane of the core is 2.5×10 -4 mD, and the porosity average value measured three times with the conventional porosity measuring instrument (instrument model is: fine and micro Gaobo JW-RB) that adopts the static volumetric method is 3.5%, and this result is very close to the device measurement result of the present invention, Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com