Preparation process of fatty acid isooctyl ester

A technology of isooctyl fatty acid and preparation process, which is applied in the directions of fatty acid esterification, fatty acid production, fatty acid chemical modification, etc., can solve the problems of large amount of isooctyl alcohol and catalyst, difficult industrialization of microwave-assisted method, and difficult separation of catalyst, etc. Achieve the effect of reducing product pollution, easy separation, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] In a particularly preferred embodiment, the preparation method of the supported catalyst comprises the following steps:

[0074] a) Prepare an aqueous solution of active substances (such as acid sulfate or p-toluenesulfonic acid) with a concentration of about 2wt% to saturation;

[0075] b) weighing a corresponding amount of carrier, adding it to the solution obtained in a), stirring evenly, and soaking for about 2-48h; and

[0076] c) Filter, and dry the filter cake at about 100-200°C for about 2-10 hours.

[0077] In a particularly preferred embodiment, the fatty acid isooctyl ester preparation process of the present invention comprises the following steps:

[0078] 1) Mix fatty acid, isooctyl alcohol and catalyst in a reactor and react under heating conditions;

[0079] 2) After the reaction, remove the isooctyl alcohol and / or the catalyst to obtain the crude product of fatty acid isooctyl ester; and

[0080] 3) Deacidify the obtained crude product to obtain the f...

Embodiment

[0094] The present invention is described exemplarily through examples below, and it should be understood that these examples are only for the purpose of illustration and do not constitute a limitation to the present invention.

[0095] Reagents and Assays

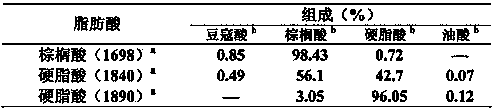

[0096] 1) Various fatty acids used in all examples and comparative examples were provided by Yihai (Lianyungang) Oil Chemical Industry Co., Ltd. Specifically, the carbon composition of the fatty acids used in the examples is shown in Table 1 below.

[0097] Table 1. Composition of fatty acids

[0098]

[0099] Note: a The name of the fatty acid here represents a general term;

[0100] b Fatty acid names here refer to pure fatty acids with a specified number of carbon atoms.

[0101] 2) In addition, in the present invention, the relevant indicators of the obtained product are detected by the following detection methods:

[0102] Product acid value determination method: AOCS Te 1a-64;

[0103] Product hydroxyl value ...

Embodiment 1

[0111] In a 250mL four-necked flask equipped with a stirrer, add 0.25mol of palmitic acid (1698) and 0.325mol of isooctyl alcohol, add 0.05wt% activated carbon-loaded sodium bisulfate, and protect it with nitrogen gas. The reaction temperature was raised to 150°C, and after 5 hours of heat preservation, vacuum distillation was carried out to remove excess alcohol. Cool to room temperature and filter to obtain a crude product with an acid value of 0.15 mgKOH / g. The crude product was washed three times with 200 mL of water, dehydrated in vacuum, added 0.2 wt% activated carbon, stirred for 1 h, and filtered to obtain the product of isooctyl palmitate. The acid value of the product is 0.06mgKOH / g, the hydroxyl value is 0.2mgKOH / g, and the color is 11. The esterification rate was 99.96%, and the yield was 95.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com