Lubricating oil composite type antifoaming agent and application thereof

A technology of anti-foaming agent and lubricating oil, which is applied in the field of compound anti-foaming agent and its preparation, can solve the problems such as high-temperature anti-foaming can not be effectively solved, achieve improved dispersion effect, good high-temperature anti-foaming performance, and improve high-temperature anti-foaming performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

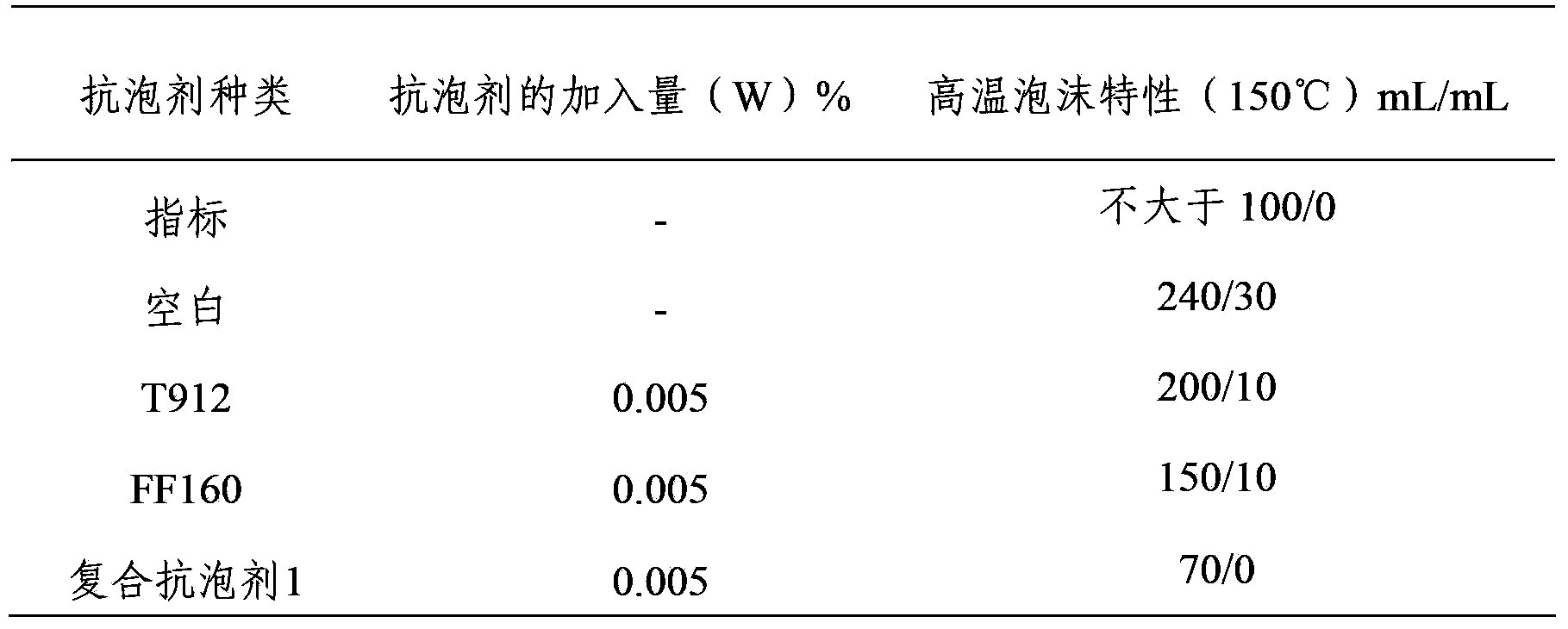

[0027] Fluorine-containing silicone oil antifoaming agent (FF160), acrylate copolymer antifoaming agent (T912), amyl ketone, and solvent oil for the paint industry (qualified product No. 200 solvent oil) according to 1%, 5%, 15%, 79 % of the mixture, at 40°C, mechanically stirred evenly, made into composite antifoam agent 1, and then added to internal combustion engine oil SL5W-30 according to the required amount, and compared with the use of a single antifoam agent, the oil The test results of high temperature foam properties are shown in Table 1.

[0028] Table 1 High temperature foam properties of composite antifoam agent 1

[0029]

[0030] It can be seen from Table 1 that in the three cases of adding no antifoaming agent to SL5W-30, adding a single antifoaming agent (T912 and FF160) and adding composite antifoaming agent 1, the SL5W-30 with composite antifoaming agent 1 The oil has the smallest static foam volume and the best high-temperature foam characteristics (150...

Embodiment 2

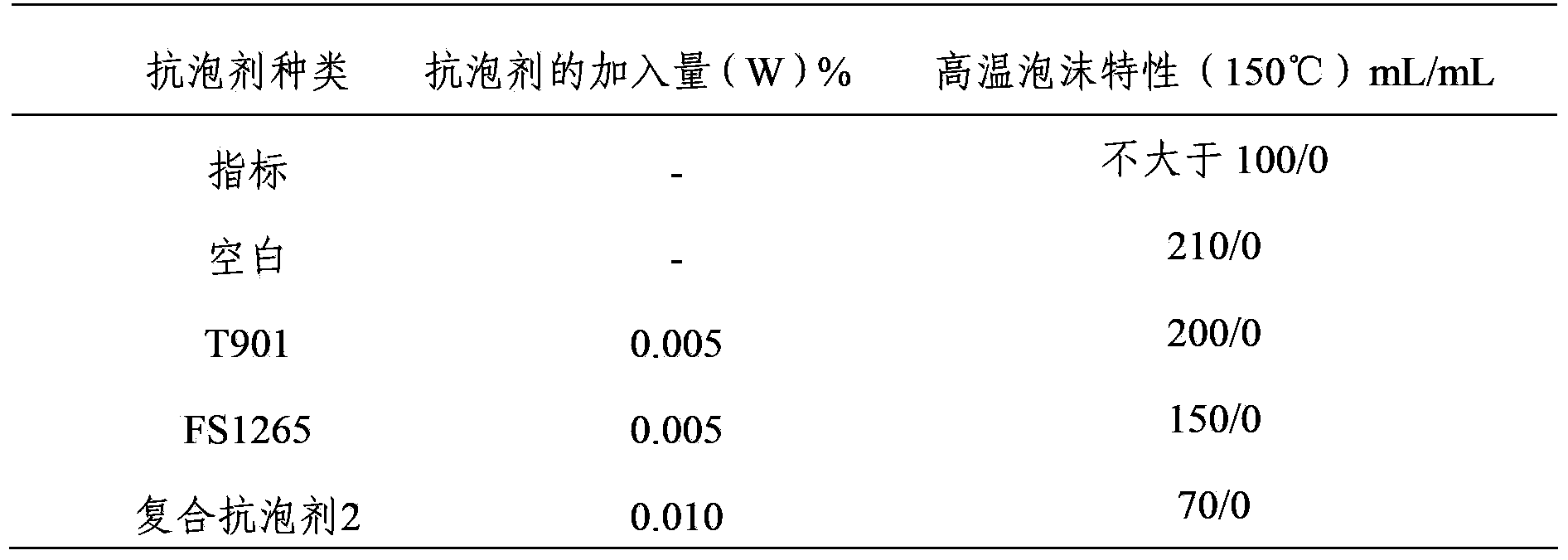

[0032] Mix fluorine-containing silicone oil (FS1265), silicone oil-type antifoaming agent (T901), pentanone, and aviation kerosene (3# aviation kerosene) according to the ratio of 1%, 1%, 20%, and 78%, and stir at 50°C Evenly, compound antifoam agent 2, and then add it to internal combustion engine oil SM5W-30 according to the required amount, and compare with a single antifoam agent, the test results of the high temperature foam characteristics of the oil are shown in Table 2.

[0033] Table 2 High temperature foam characteristics of composite antifoam agent 2

[0034]

[0035] It can be seen from Table 2 that in SM5W-30 without adding antifoaming agent, adding a single antifoaming agent (T901 and FS1265) and adding composite antifoaming agent 2, SM5W-30 with composite antifoaming agent 2 The oil has the smallest static foam volume and the best high-temperature foam characteristics (150°C), which can meet the requirements of SM5W-30. It shows that the high-temperature ant...

Embodiment 3

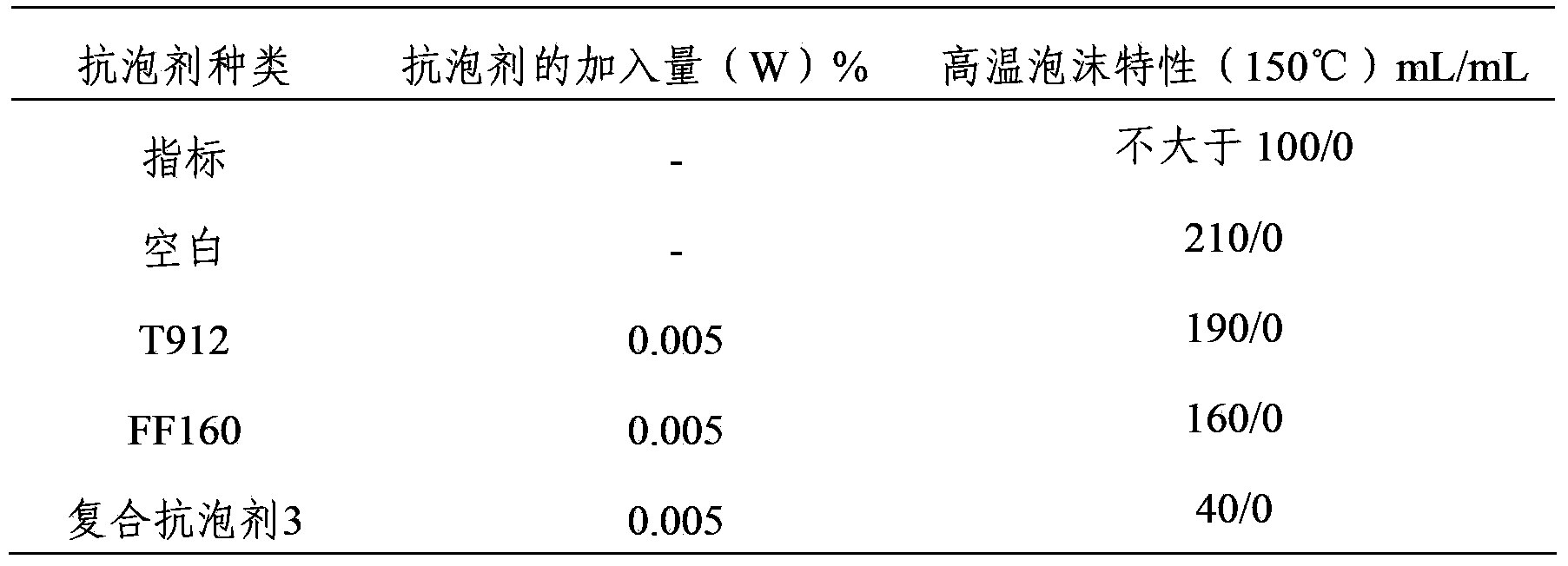

[0037] Fluorine-containing silicone oil (FF160), acrylate copolymer antifoaming agent (T912), amyl ketone, and solvent oil for the paint industry (qualified product No. 200 solvent oil) are used in proportions of 2%, 8%, 25%, and 65%. Mixed, at a temperature of 30°C, mechanically or manually stirred to make a compound antifoaming agent 3, and then added to internal combustion engine oil SM5W-30 according to the required amount, and compared with using an antifoaming agent alone, the oil product The test results of high temperature foam properties are shown in Table 3.

[0038] Table 3. High temperature foam characteristics of composite antifoam agent 3

[0039]

[0040] It can be seen from Table 3 that in SM5W-30 without adding antifoaming agent, adding a single antifoaming agent (T912 and FF160) and adding composite antifoaming agent 3, SM5W-30 adding composite antifoaming agent 3 The oil has the smallest static foam volume and the best high-temperature foam characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com