Device for treating high-concentration ammonia nitrogen in refinery wastewater by using surface activity catalyst

A technology for surface activity and refinery wastewater, applied in the direction of reduced water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low ammonia nitrogen removal rate, large pollution, high cost, etc., and achieve simple device process , high removal rate of ammonia nitrogen, and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

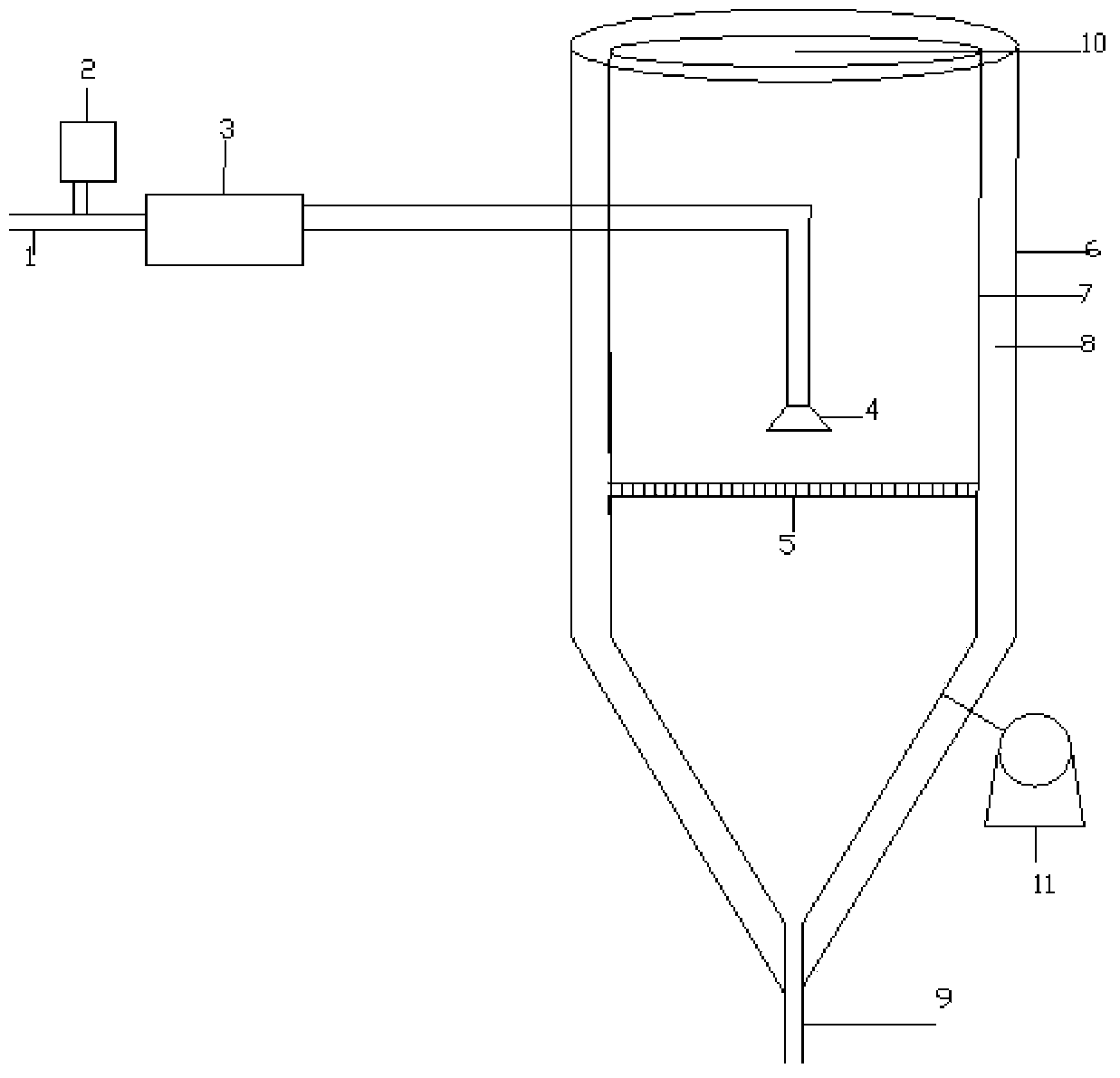

[0017] As shown in Figure 1, the present invention provides surface-active catalyst treatment high-concentration ammonia-nitrogen device in refinery waste water, and this device is made up of waste water inlet (1), surfactant inlet (2), pipe mixer (3), injection pipe (4), Heavy metal catalyst net (5), denitrification cylinder shell (6), denitrification cylinder inner shell (7), waste water channel (8), waste water outlet (9), water intake (10) and blower (11); surface activity The agent inlet (2) is located above the pipeline mixer (3) and is connected with the pipeline mixer (3), and the waste water inlet (1) is connected with the pipeline mixer (3); the pipeline mixer (4) is located at the heavy metal catalyst network (5 ) above; the ratio of the cuboid to the cone of the denitrification cylinder shell (6) is 3:2, and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com