Preparation method of ordered graphene porous membrane

A graphene film and graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of lack of graphene dispersion system pretreatment and pre-orientation, poor product structure order, complicated operation, etc., and achieve regular structure. , high degree of order, quick and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Treat 1 part by weight of graphene and 5 parts by weight of water at 20° C. with 10 KHz ultrasound for 1 hour to obtain a graphene dispersion.

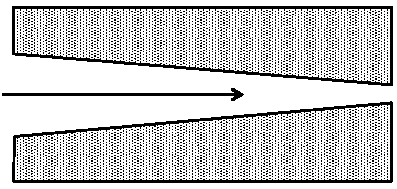

[0024] 2) Extrude the graphene dispersion at a speed of 500 mL / h in a straight die preparation device, and then stay in liquid nitrogen for 50 seconds to solidify into a film, and then further freeze-dry or critical freeze-dry After 30 hours, a graphene porous ordered film was finally obtained.

[0025] Such as Figure 4 As shown, the obtained graphene ordered porous film has a good orientation arrangement structure and a regular pore structure. The graphene sheets are arranged and piled up in the axial direction to form through holes along the film extrusion direction, and the density is 0.03-0.04g / cm 3 , the tensile strength is 10-15MPa, the compressive strength is 2-4MPa, the thickness of the film is 100-500 microns, the width is 0.1-100 cm, the elongation at break is 8-10%, the conductivity is greater than 1000S / m, the ...

Embodiment 2

[0027] 1) Treat 1 part by weight of graphene and 100 parts by weight of water at 60° C. for 10 hours with a 5 KHz ultrasonic wave to obtain a graphene dispersion.

[0028] 2) The graphene dispersion was continuously extruded at a speed of 300 mL / h in the preparation device of the inline die, and then stayed in liquid nitrogen for 20 seconds to solidify into a film, and then further critically freeze-dried for 24 hours, and finally A graphene porous ordered film is obtained.

[0029] The obtained graphene ordered porous membrane, the graphene sheets are arranged and stacked along the axial direction to form through holes along the extrusion direction of the membrane, and the density is 0.03-0.04g / cm 3 , the tensile strength is 10-15MPa, the compressive strength is 2-4MPa, the thickness of the film is 100-500 microns, the width is 0.1-100 cm, the elongation at break is 8-10%, the conductivity is greater than 1000S / m, the porosity The rate is 99%. This large-porosity conductive...

Embodiment 3

[0031] 1) Treat 1 part by weight of graphene oxide and 30 parts by weight of water at 40° C. with 10 KHz ultrasound for 5 hours to obtain a graphene oxide dispersion.

[0032] 2) The graphene oxide dispersion was continuously extruded at a speed of 1000 mL / h in a preparation device with a straight die, and then stayed in liquid nitrogen for 100 seconds to solidify to form a film, and then further freeze-dried for 40 hours, Finally, an ordered porous graphene oxide porous membrane is obtained.

[0033] 3) The ordered porous graphene oxide membrane obtained in step (2) was placed in a 30% vitamin C aqueous solution for reduction for 48 hours, washed and dried to obtain a graphene porous ordered membrane.

[0034] The obtained graphene ordered porous membrane, the graphene sheets are arranged and stacked along the axial direction to form through holes along the extrusion direction of the membrane, and the density is 0.03-0.04g / cm 3 , the tensile strength is 10-15MPa, the compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com