Preparation method of nanometer metal oxide powder

A technology of oxide powder and nano-metal, applied in the direction of oxide/hydroxide preparation, rare earth metal compounds, chemical instruments and methods, etc., can solve problems such as difficult large-scale industrial production, complex and expensive equipment, and long reaction cycle. Achieve small particle size, reduce energy consumption, and narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

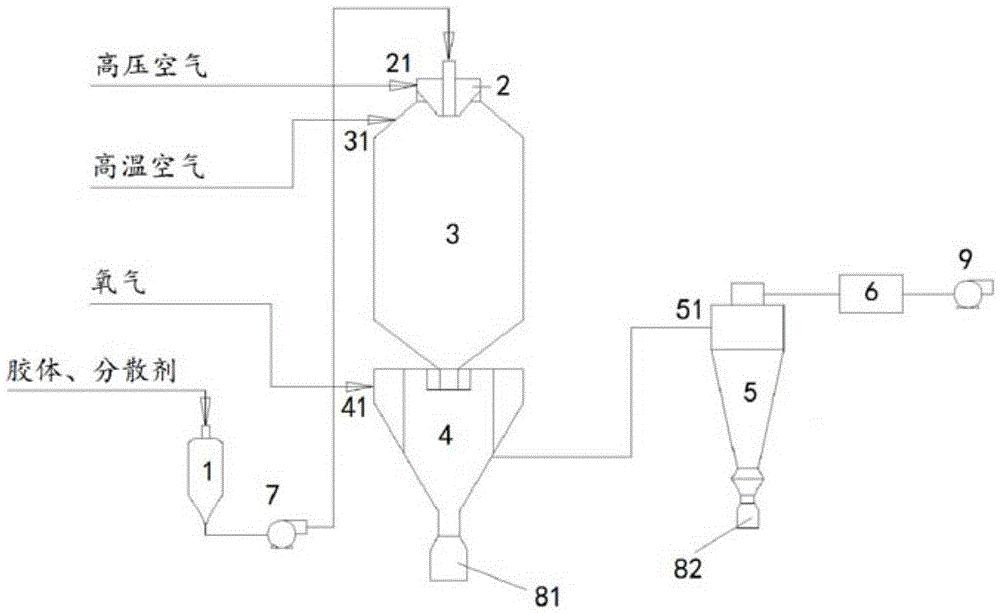

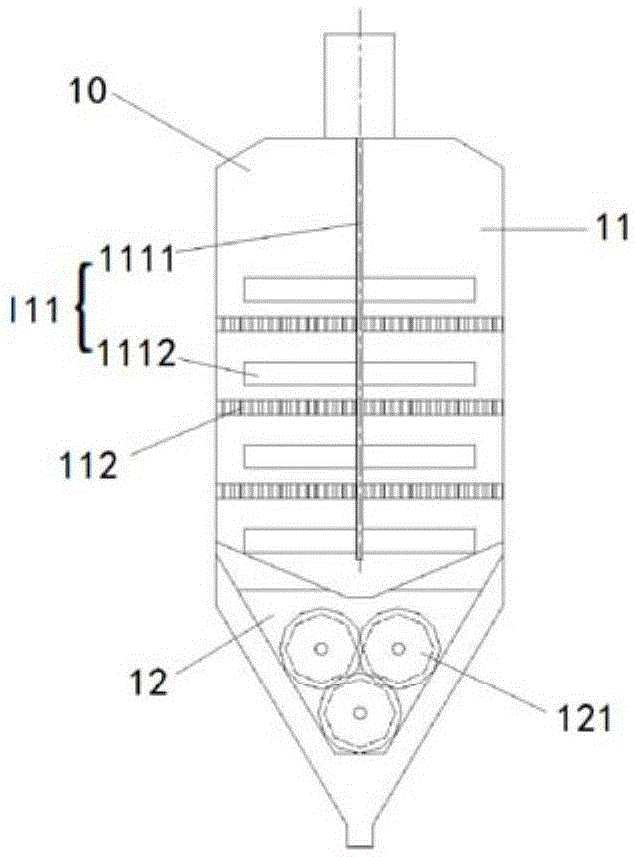

Method used

Image

Examples

Embodiment 1

[0042] (1) Configuration solution: Dissolve tin tetrachloride in water and configure it into an aqueous solution. After the solution is completely dissolved, citric acid is added to the prepared metal ion solution, and the pH value is adjusted to 6 with ammonia water.

[0043] (2) Esterification gel production: Add ethylene glycol to the solution in step (1), then put the solution in a water bath and heat it to 70°C, and esterification reaction occurs after 1 hour to form a transparent colloid.

[0044] (3) Crushing and drying: The colloid and white oil obtained in step (2) are added into the slurryer at the volume ratio of 100:9 at the same time, and the fluid slurry is made through the slurryer. Then the slurry is transported to the atomizer by the high-pressure pump and atomized by 8MPa high-pressure air, and the atomized material is quickly dried in the drying tower. At this time, the high-temperature gas in the drying tower is 300°C, and the drying time is 1s.

[0045] (...

Embodiment 2

[0048] (1) Configuration solution: Dissolve aluminum nitrate in water and configure it into an aqueous solution. After the solution is completely dissolved, glycine is added to the prepared metal ion solution, and the pH value is adjusted to 6 with ammonia water.

[0049] (2) Esterification gel making: add ethylene glycol to the solution in step (1), then put the solution in a water bath and heat it to 60° C., esterification reaction occurs after 1.5 hours, and a transparent colloid is formed.

[0050] (3) Crushing and drying: Add the colloid and white oil obtained in step (2) into the slurryer at the volume ratio of 100:8 at the same time, and make a fluid slurry through the slurryer. Then the slurry is transported to the atomizer by the high-pressure pump and atomized by 10MPa high-pressure air, and the atomized material is quickly dried in the drying tower. At this time, the high-temperature gas in the drying tower is 250°C, and the drying time is 30s.

[0051] (4) Oxygena...

Embodiment 3

[0054](1) Prepare solution: dissolve zirconium nitrate and yttrium nitrate in water according to a certain proportion, and prepare an aqueous solution. After the solution is completely dissolved, ethylenediaminetetraacetic acid is added to the prepared metal ion solution, and the pH value is adjusted to 8 with ammonium carbonate.

[0055] (2) Esterification gel making: add butanediol to the solution in step (1), then put the solution into a water bath and heat to 90° C., esterification reaction occurs after 0.5 h, and a transparent colloid is formed.

[0056] (3) Crushing and drying: Add the colloid, white oil and alcohol obtained in step (2) into the pulper at a volume ratio of 100:8 at the same time, and make a fluid slurry through the pulper. Then the slurry is transported to the atomizer by a high-pressure pump and atomized by 6MPa high-pressure air, and the atomized material is quickly dried in the drying tower. At this time, the high-temperature gas in the drying tower i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com