Belt conveyor intelligent current detection spraying system and control method

A belt conveyor and current detection technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of waste of water resources, poor dust suppression effect, low intelligence, etc., and achieve water conservation and intelligence Improvement, the effect of perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

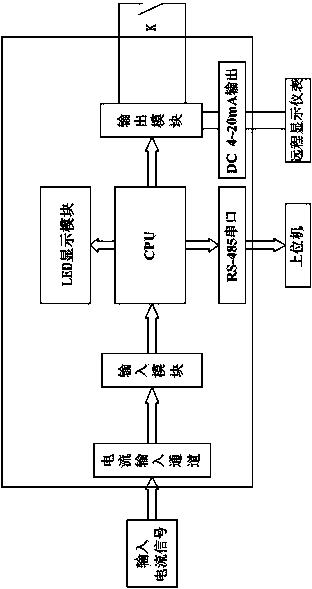

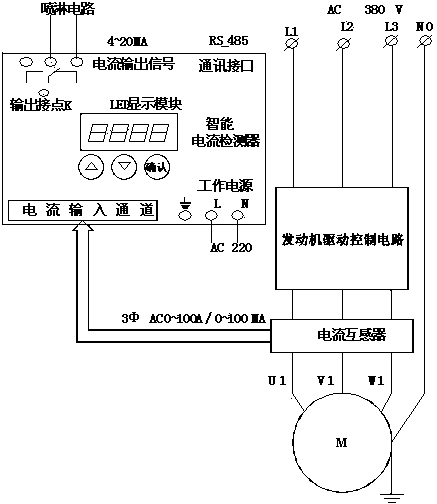

[0042] like figure 1 , figure 2As shown, the intelligent current detection spraying system of the belt conveyor includes a spraying pipeline arranged above the belt of the belt conveyor, a plurality of solenoid valves and an electrical control system arranged on the spraying pipeline. The electrical control system is composed of a power supply, an intelligent current detector, a current transformer or a frequency converter I / O board for obtaining a current signal reflecting the actual load of the belt conveyor drive motor, a spray circuit and a connecting wire. The current transformer or The output end of the inverter I / O board is electrically connected to the input module of the intelligent current detector through the current input channel, and the spray circuit is composed of a power supply, an output contact K electrically connected to the output module of the intelligent current detector, and an output contact K is connected in series with inspection / sprinkling changeov...

Embodiment 2

[0064] see Figure 6-a to Figure 6-c , the spray pipeline adopts a pipeline solenoid valve arranged along the length direction of the belt conveyor, and there is only one first spray section in the overall length direction, and the relay is an intermediate relay K1 for controlling the pipeline solenoid valve. When the full-length spray section is used, the start-up time of the intermediate relay K1 controlling the pipeline solenoid valve is Tsd1, that is

[0065] Tsd1=[(15%~30%)L÷v]+ΔT

[0066] In the formula, L is the total length of the belt conveyor belt, (15%-30%) L means that the material carried by the belt conveyor is 15%-30% of the total length of the belt from the tail drain to the tail drain, and v is the belt speed and delay time ΔT=10s, which is set for the internal program timer of the intelligent current detector, which is used to avoid the starting time of the drive motor and prevent external signal interference, and avoid misoperation of the spray circuit. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com