Processing method of composite plastic materials for high-toughness building templates

A processing method and technology for building formwork, applied in the field of building construction formwork, can solve the problems of insufficient rigidity, difficult blending effect, easy deformation, etc., and achieve the effects of avoiding environmental pollution, improving processing fluidity, and improving toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

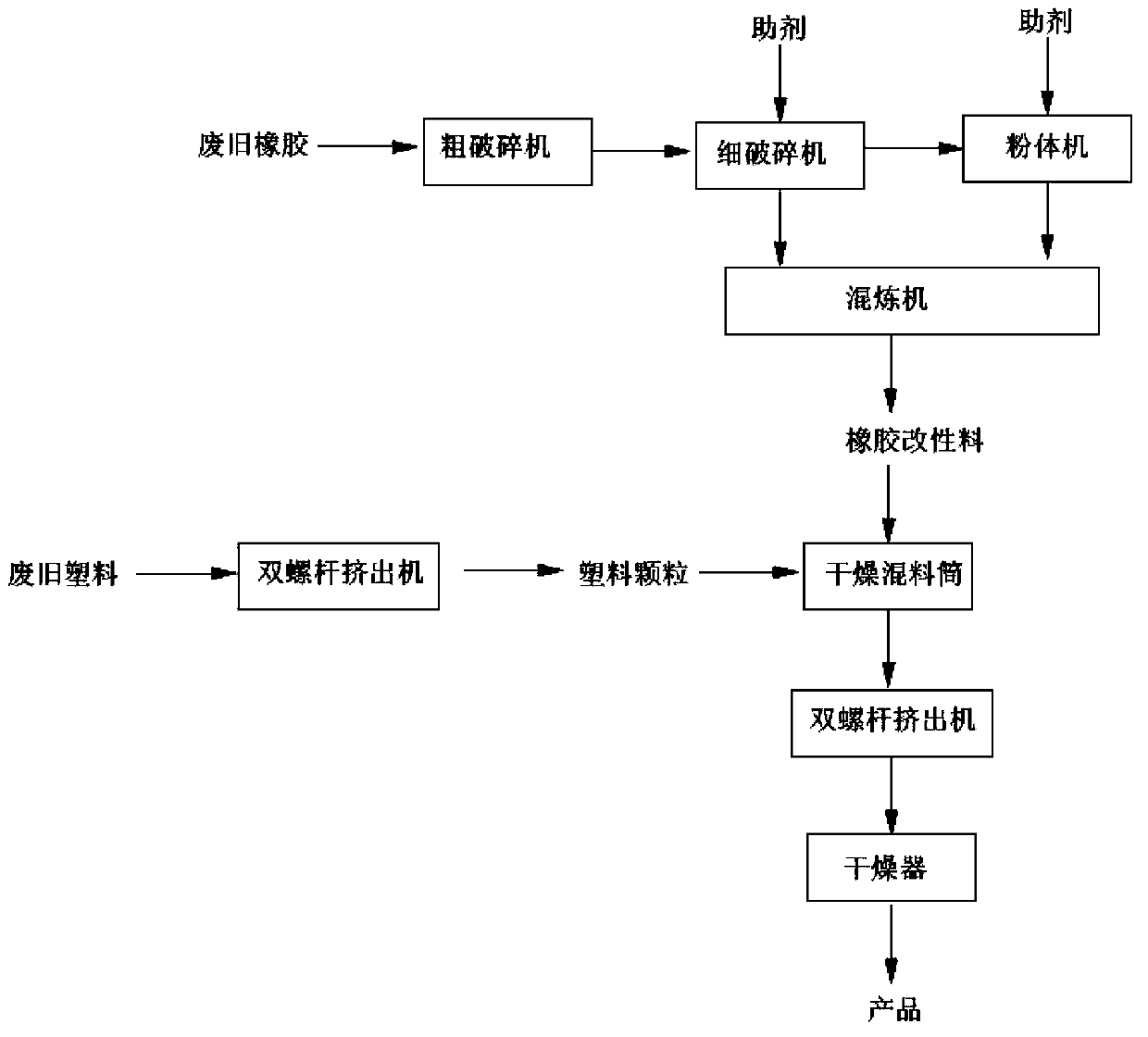

[0033] The present invention is a processing method of composite plastic material for high-toughness building formwork, such as figure 1 As shown, the processing method includes the following steps:

[0034] S1. The waste plastic is melted, extruded, cooled, and pelletized into uniform plastic particles of regular size through a twin-screw extruder.

[0035] S2. Crushing waste rubber into micron rubber powder.

[0036] S3. Mix the rubber powder and the auxiliary agent accounting for 1-15% of the rubber weight evenly, and let stand for 0.5-24h to obtain the mixture of the rubber powder and the auxiliary agent; the auxiliary agent is composed of 10-40% binder, 10~40% compatibilizer, 5~20% plasticizer, 1~5% lubricant and 0~25% coupling agent. Wherein, the adhesive is an ethylene-vinyl acetate copolymer, wherein the vinyl acetate structural unit accounts for 5-28% of the weight of the copolymer, and the compatibilizer is a chlorinated polyolefin, an anhydride grafted modified poly...

Embodiment 2

[0042] The present invention is a kind of processing method of composite plastic material for high-tough building formwork, and this processing method comprises the following steps:

[0043] S1. The waste plastic is melted, extruded, cooled, and pelletized into uniform plastic particles of regular size through a twin-screw extruder.

[0044] S2. Use a shredder to crush the waste rubber into rubber particles with a size of 1-10mm.

[0045] S3. Mix the rubber particles and the auxiliary agent accounting for 1-15% of the weight of the rubber evenly, and let stand for 0.5-24h to obtain a mixture of the rubber particle and the auxiliary agent; the composition and content of the auxiliary agent are the same as in Example 1.

[0046] S4. Mix the mixture of rubber granules and additives through the mixing equipment, extrude from the machine head, and cut into pellets to obtain rubber modified materials with a size of 1~7cm.

[0047] S5. Measure the rubber modified material and the pl...

Embodiment 3

[0051] On the basis of Example 2, this embodiment is preferred: in the step S5, chopped glass fibers are also mixed in the mixing barrel; wherein the chopped glass fibers are glass fiber leftovers or broken materials of waste glass fiber mats, The addition amount of chopped glass fiber is no more than 50% of the total weight of rubber modified material and plastic particles in the mixing barrel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com