Low-back-pressure penetration electric arc welding device and method

A technology of arc welding and welding equipment, applied in arc welding equipment, welding equipment, welding accessories, etc., which can solve problems such as difficulties, increasing tendency of small hole instability, and inability of plasma arc to penetrate, so as to achieve simple equipment and improve weld seam The effect of forming the backside and increasing the weldable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

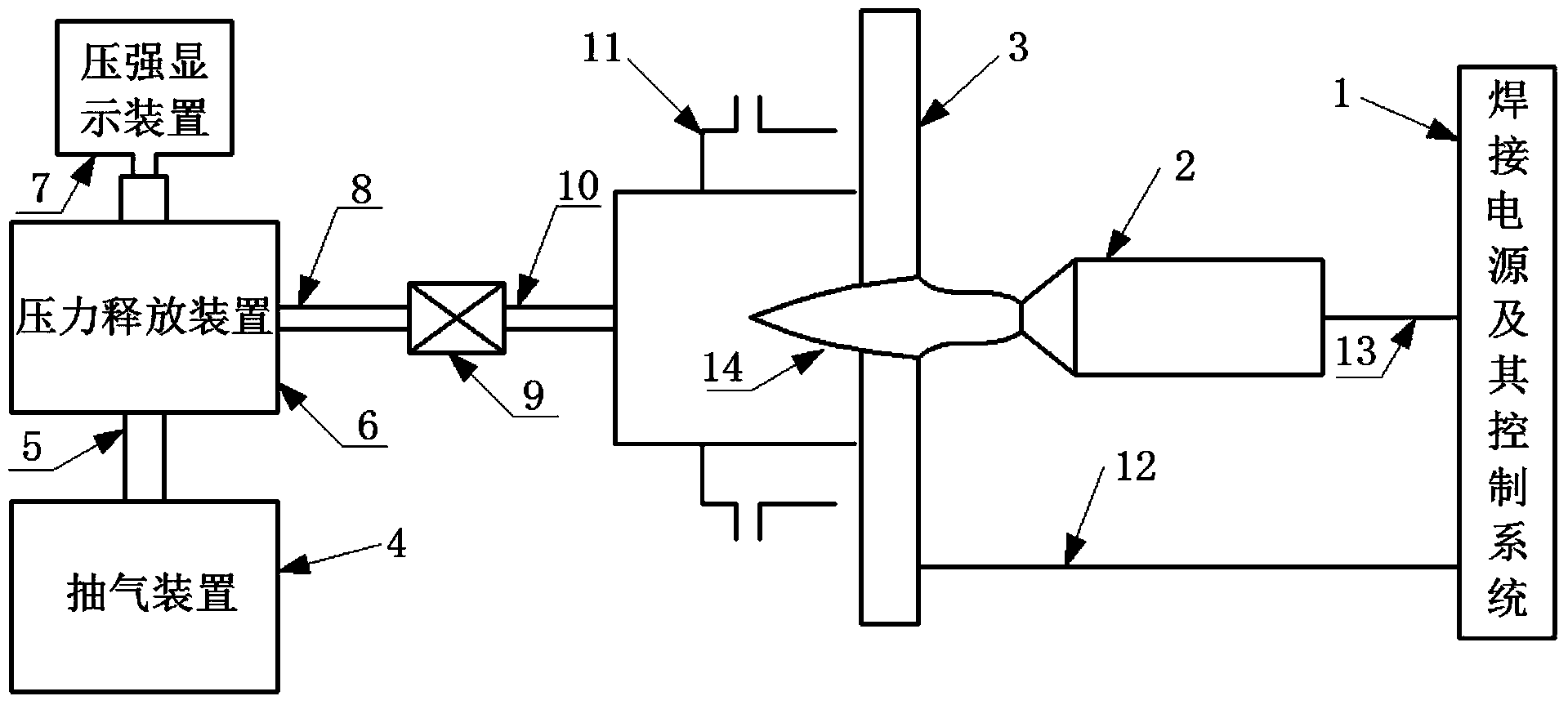

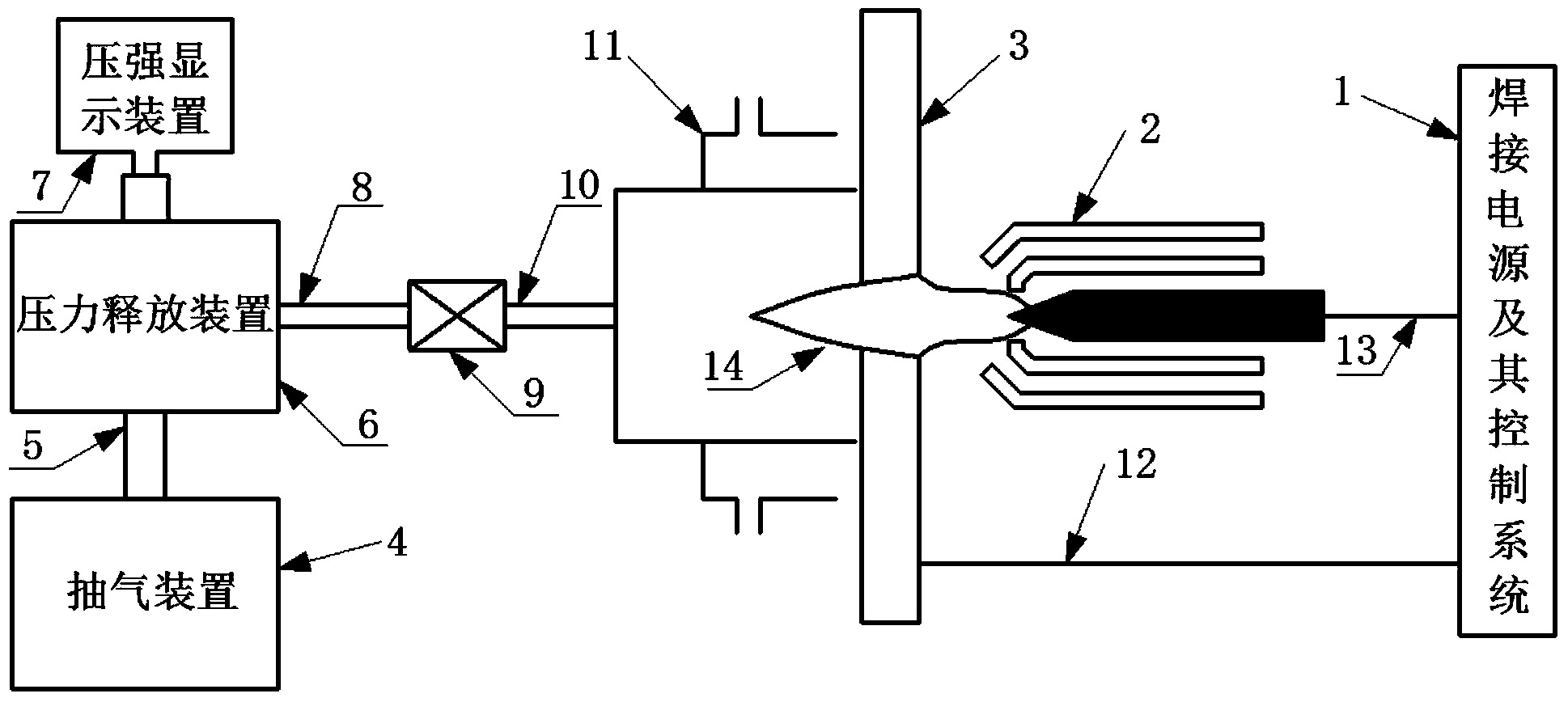

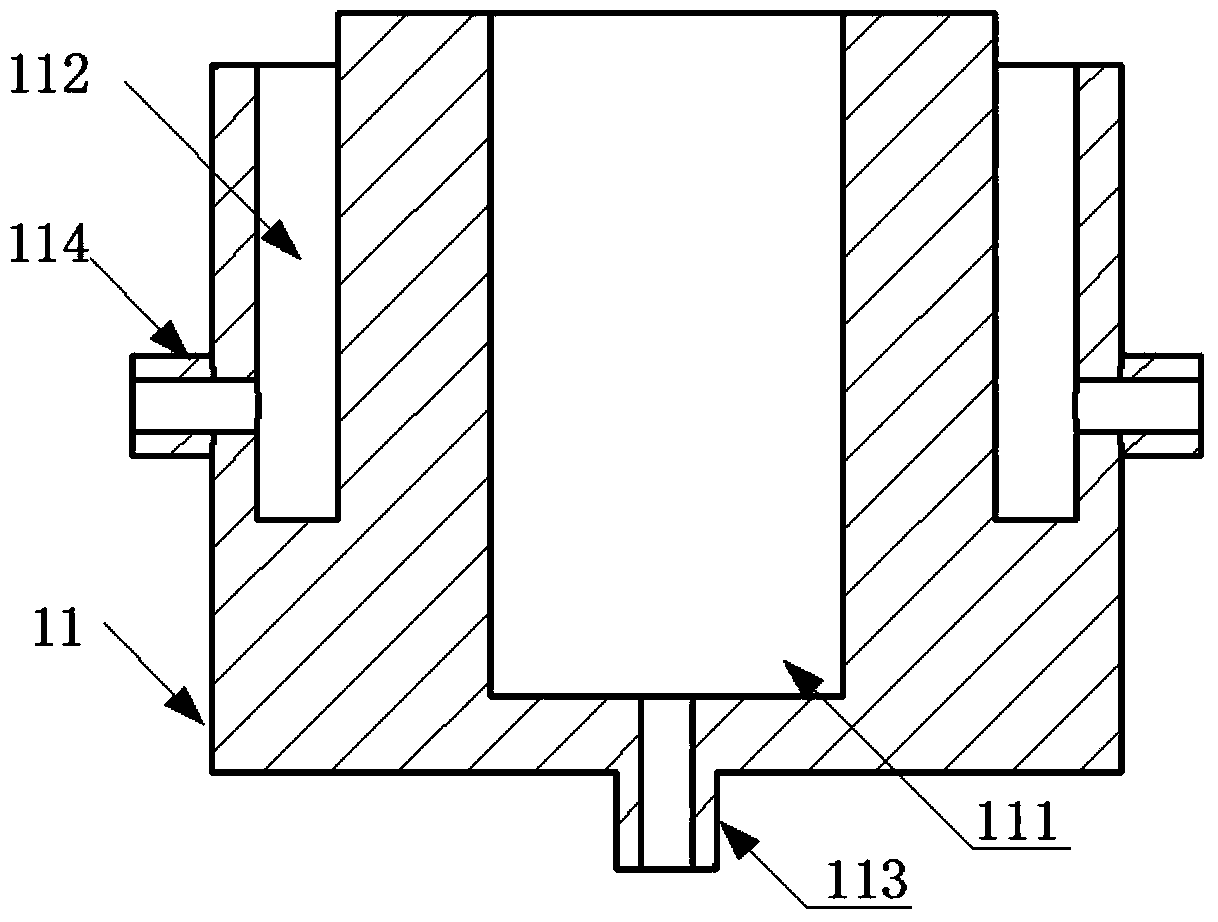

[0021] Embodiments of the present invention will be specifically described below with reference to the drawings. Such as figure 1 Shown is a schematic diagram of the implementation device of this welding method. The low back pressure penetrating arc welding device mainly includes a welding power source and its control system 1, a welding torch 2, a welding workpiece 3, an air extraction device 4, a pressure release device 6, and a pressure display Device 7, valve 9 and low back pressure protection device 11, in which air extraction device 4—air guiding line A5—pressure release device 6—air guiding line B8—valve 9—air guiding line C10—low back The pressure protection device 11 forms a gas pipeline, the pressure display device 7 is connected with the pressure release device 6, the welding power supply and its control system 1——welding cable A12——welding workpiece 3—welding torch 2——welding cable B13——welding The power supply and its control system 1 form an electrical circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com