A manufacturing process of large-diameter thick-walled high-strength welded pipe

A manufacturing process and large-diameter technology, applied in the field of welded pipe manufacturing, can solve problems such as the inability to effectively guarantee the quality of the weld, affect the dimensional accuracy of the pipe, and the large amount of welding groove processing, so as to achieve good promotion and application value, improve production efficiency, Effect of reducing welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

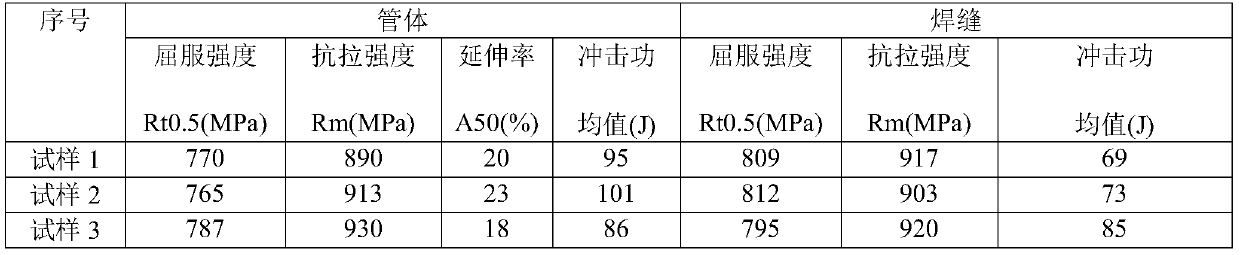

Embodiment 1

[0029] A large-diameter thick-walled high-strength welded pipe adopts hot-rolled steel plates with a yield strength of 750MPa, a tensile strength of 890MPa, and a thickness of 14mm. The specifications of the welded pipe are: diameter 273mm, wall thickness 14mm. The specific steps of its manufacturing process are as follows:

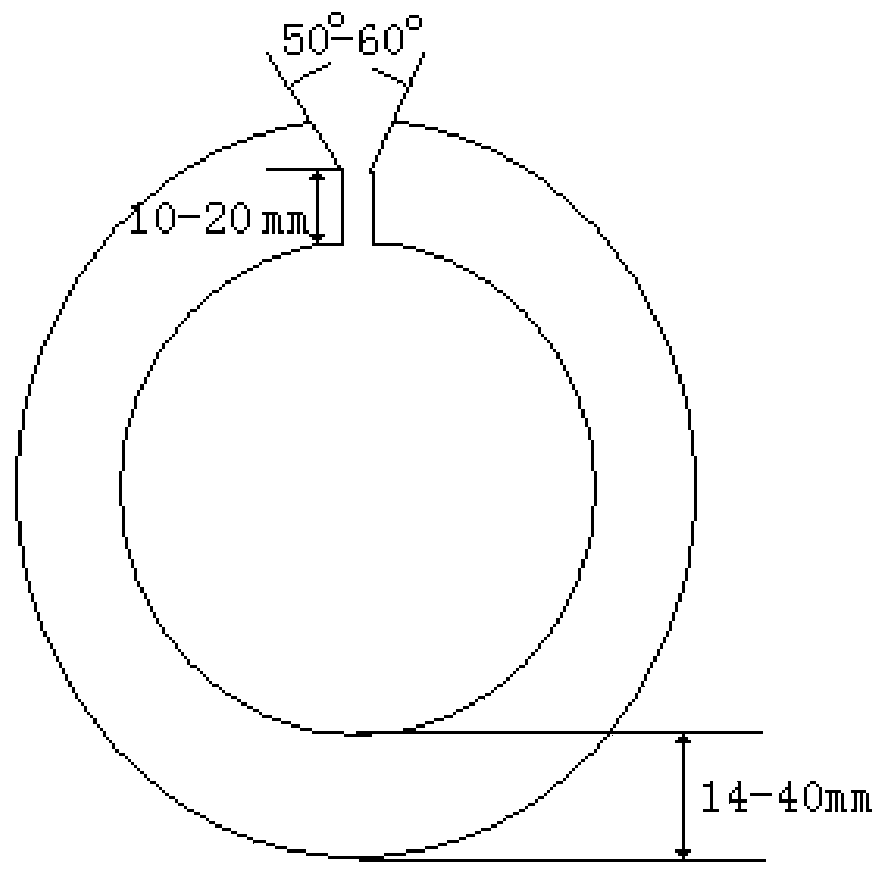

[0030] (1) The edge of the high-quality hot-rolled steel plate is processed into a Y-shaped welding groove, the groove angle is 50°, and the length of the blunt edge is 10mm;

[0031] (2) Perform flaw detection on the plate body obtained in step (1) without defects, and after forming (the steel plate is formed into a pipe body after being pressed into an O shape), perform high-frequency welding on the blunt edge of the Y-shaped welding groove, and the welding frequency is 150KHz , the welding speed is 20m / min, the welding thickness is 10mm, and the internal burrs are removed after welding;

[0032] Then perform submerged arc welding on the groove of the Y...

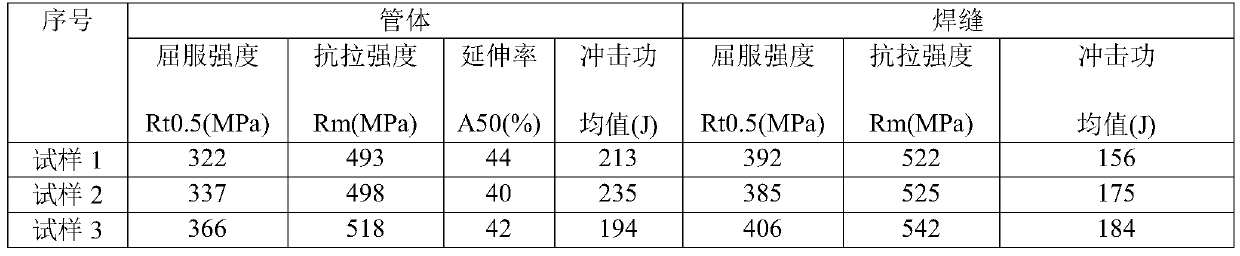

Embodiment 2

[0037] A large-diameter thick-walled high-strength welded pipe adopts hot-rolled steel plates with a yield strength of 235MPa, a tensile strength of 480MPa, and a thickness of 40mm. The specifications of the welded pipe are: diameter 660mm, wall thickness 40mm. The specific steps of its manufacturing process are as follows:

[0038] (1) The edge of the high-quality hot-rolled steel plate is processed into a Y-shaped welding groove, the groove angle is 60°, and the length of the blunt edge is 20mm;

[0039] (2) Perform flaw detection on the plate body obtained in step (1) without defects. After forming, carry out high-frequency welding on the blunt edge of the Y-shaped welding groove. The welding frequency is 100KHz, the welding speed is 14m / min, and the welding thickness is 20mm. Remove internal burrs;

[0040] Then, carry out submerged arc welding on the groove of the Y-shaped welding groove, select 500Mpa solid core submerged arc welding wire to match SJ101 flux, 3 wire subm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com