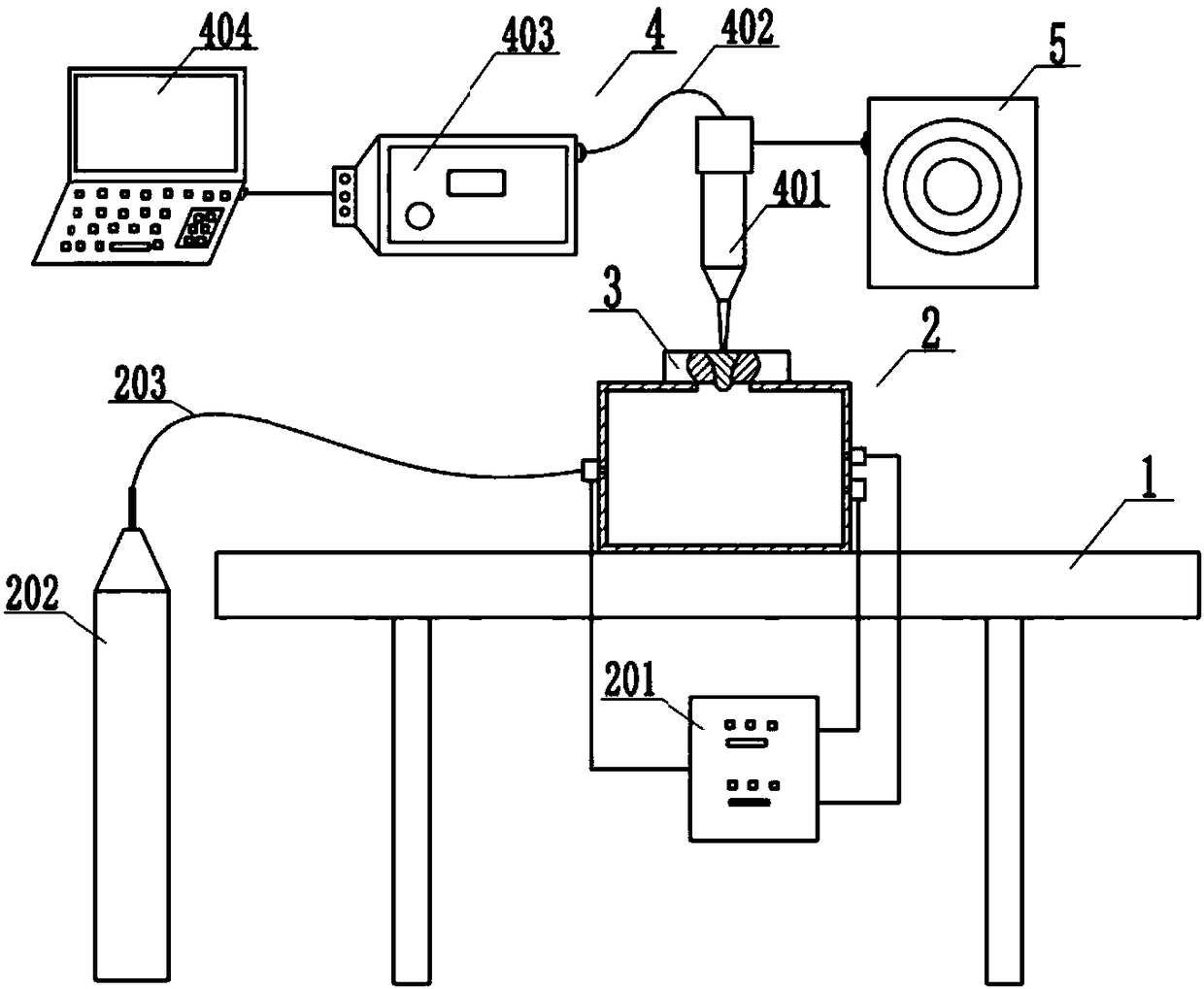

Gas buoyancy auxiliary welding device and welding method utilizing same

An auxiliary welding and buoyancy technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unbalanced surface tension, poor weld quality, and affecting welding applications, etc., to achieve simple structure and improve welding quality , Eliminate the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

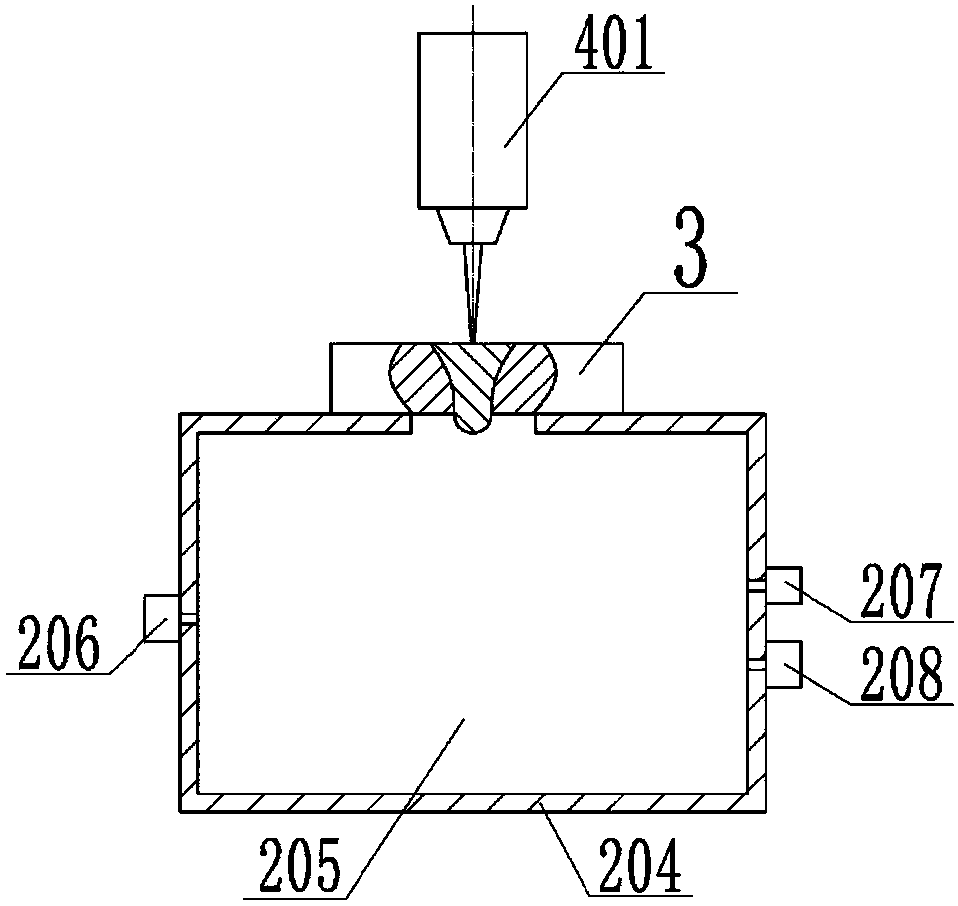

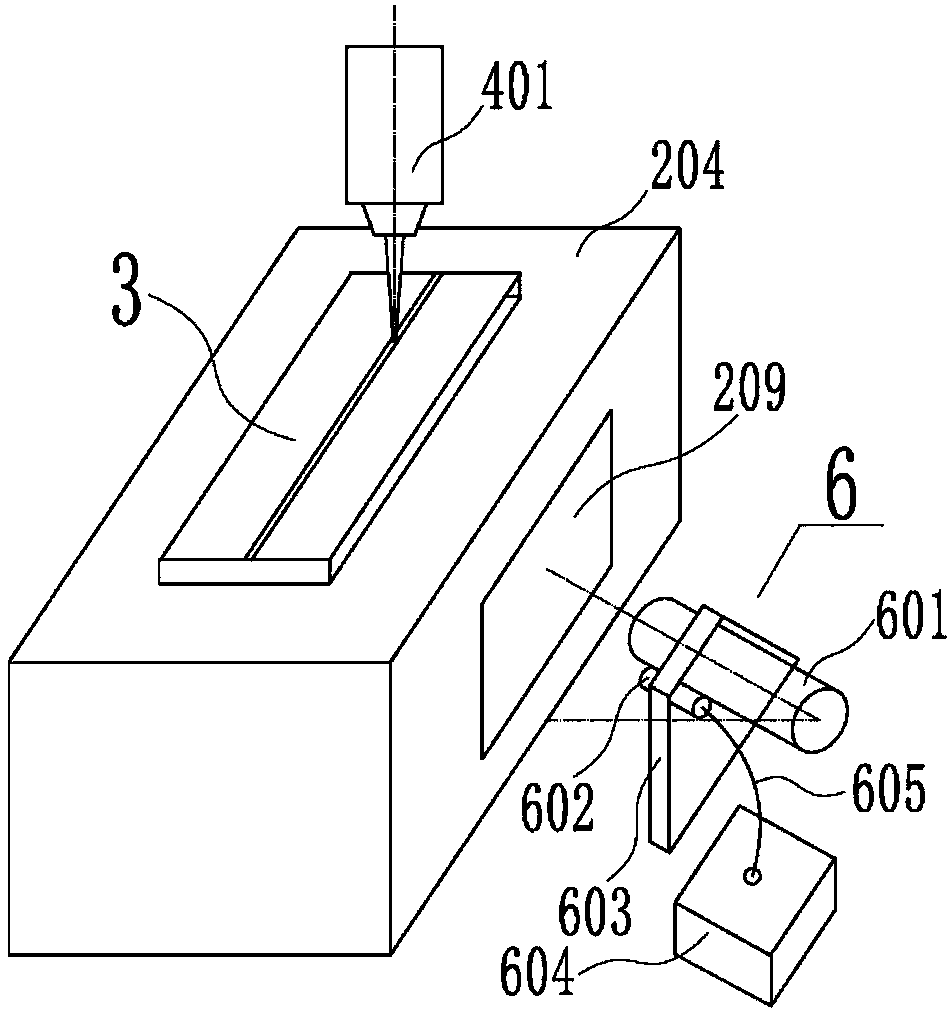

Method used

Image

Examples

example 1

[0067] The morphology of the weld seam on the upper and lower surfaces of 316L stainless steel with a thickness of 16mm was tested and observed. The adopted process parameters were laser power 16kW and welding speed 0.65m / min. The gravity on the surface is:

[0068] p h =ρg 0 h=7.98×9.8×16≈1.3kPa

[0069] Among them, ρ is the density of 316L stainless steel liquid, g 0 is the gravity coefficient, about 9.8m / s 2 , h is the thickness of the specimen.

[0070] Such as Figure 5 The picture shown shows the topography of the weld seam (a) and the bottom surface of the weld seam (b) without air pressure support. The weld seam cutting marks on the top surface are very obvious, while the weld seam on the bottom surface is wider , Welding quality is extremely poor. Such as Image 6 The figure shown shows the topography (a) of the upper surface of the welding seam and the topography (b) of the bottom surface of the welding seam of the thick plate with air support. Compared with ...

example 2

[0072] The morphology of the weld seam on the upper and lower surfaces of 20mm thick 316LN stainless steel was tested and observed. The adopted process parameters were laser power 16kW and welding speed 0.80m / min. During the welding process, for the specimen 2 used in this test, the lower surface of the molten pool The gravitational force is:

[0073] p h =ρg 0 h=7.98×9.8×20≈1.6kPa

[0074] Among them, ρ is the density of 316LN stainless steel liquid, g 0 is the gravity coefficient, about 9.8m / s 2 , h is the thickness of the specimen.

[0075] Such as Figure 7 The figure shown in the figure shows the topography (a) of the upper surface of the welding seam and the topography (b) of the lower surface of the welding seam without air pressure support. It can be seen that the upper surface of the weld has serious subsidence and the lower surface has a huge Hump, poor solder quality. Such as Figure 8 The figure shown shows the topography (a) of the upper surface of the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com