Preparation method of catalyst/adsorption material with diatomite as carrier

An adsorption material, diatomite technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of large equipment, easy poisoning of adsorbents, complicated processes, etc., and achieve reasonable pore distribution and catalytic activity. The effect of improving, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

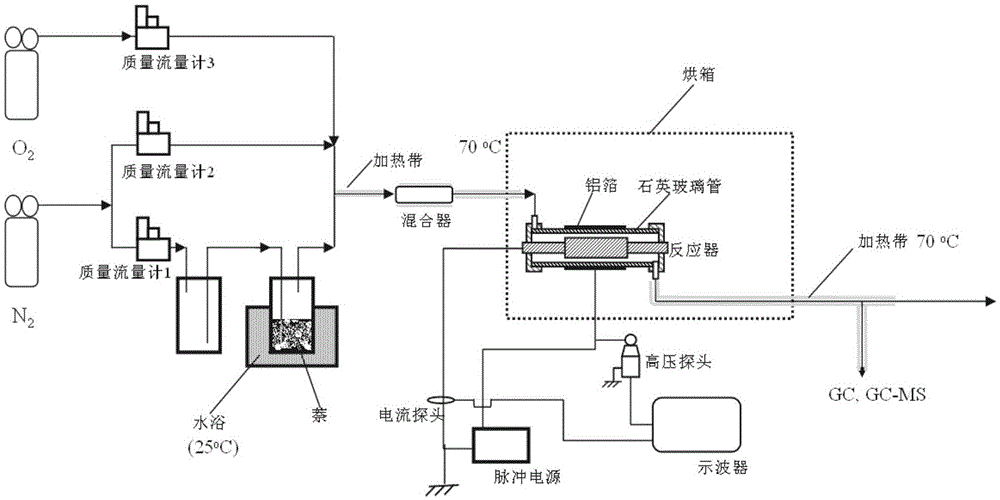

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, a kind of preparation method of catalysis / adsorption material, carries out following steps successively:

[0059] 1), the diatomite is purified according to the above-mentioned method one, and the purified diatomite is obtained;

[0060] 2), at room temperature, weigh 3 g of purified diatomite, add 45 g of absolute ethanol, and stir magnetically (stirring time is 0.5 hour), thereby forming diatomite-absolute ethanol slurry;

[0061] Place the diatomite-dehydrated ethanol pulp on a magnetic stirrer, and under the action of magnetic stirring, add manganese nitrate aqueous solution 2ml (containing 3g manganese nitrate), alumina 0.3 g and 0.3g of glass fiber powder, then add dropwise 0.09g of 65% concentrated nitric acid and 20g of deionized water, and mix and stir for 24 hours;

[0062] 3), using deionized water to centrifugally wash the product of step 2) until the eluent is neutral; obtain the washed pulp;

[0063] 4) The above-mentioned washed pulp was d...

Embodiment 2

[0064] Embodiment 2, a kind of preparation method of catalysis / adsorption material, carries out following steps successively:

[0065] 1), the diatomite is purified according to the above-mentioned method one, and the purified diatomite is obtained;

[0066] 2) At room temperature, weigh 3 g of purified diatomite, add 45 g of absolute ethanol, and stir magnetically (stirring time is at least 0.5 hours), thereby forming a diatomite-absolute ethanol slurry;

[0067] Place the diatomite-dehydrated ethanol pulp on a magnetic stirrer, and under the action of magnetic stirring, add manganese nitrate aqueous solution 4ml (containing 6g manganese nitrate), aluminum oxide 0.3 g, 0.3g of glass fiber powder, then add dropwise 0.09g of 65% concentrated nitric acid and 20g of deionized water, and mix and stir for 24 hours;

[0068] 3), using deionized water to centrifugally wash the product of step 2) until the eluent is neutral; obtain the washed pulp;

[0069] 4) The above-mentioned wa...

Embodiment 3

[0070] Embodiment 3, a kind of preparation method of catalysis / adsorption material, carries out following steps successively:

[0071] 1), the diatomite is purified according to the above-mentioned method one, and the purified diatomite is obtained;

[0072] 2) At room temperature, weigh 3 g of purified diatomite, add 45 g of absolute ethanol, and stir magnetically (stirring time is at least 0.5 hours), thereby forming a diatomite-absolute ethanol slurry;

[0073] Place the diatomite-dehydrated ethanol pulp on a magnetic stirrer, and under the action of magnetic stirring, add manganese nitrate aqueous solution 6ml (containing 9g manganese nitrate), aluminum oxide 0.3 g, 0.3g of glass fiber powder, then add dropwise 0.09g of 65% concentrated nitric acid and 20g of deionized water, and mix and stir for 24 hours;

[0074] 3), using deionized water to centrifugally wash the product of step 2) until the eluent is neutral; obtain the washed pulp;

[0075] 4) The above-mentioned wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com