Impinging stream structure and impinging stream and rotary material packed bed device

A technology of rotating packed bed and impingement flow is applied in the field of strengthening liquid-liquid rapid micro-mixing reaction devices, which can solve the problems of unsatisfactory and uneven mixing effect of impinging flow structure, and achieve improved micro-mixing effect, reduction of by-products, and saving of by-products. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

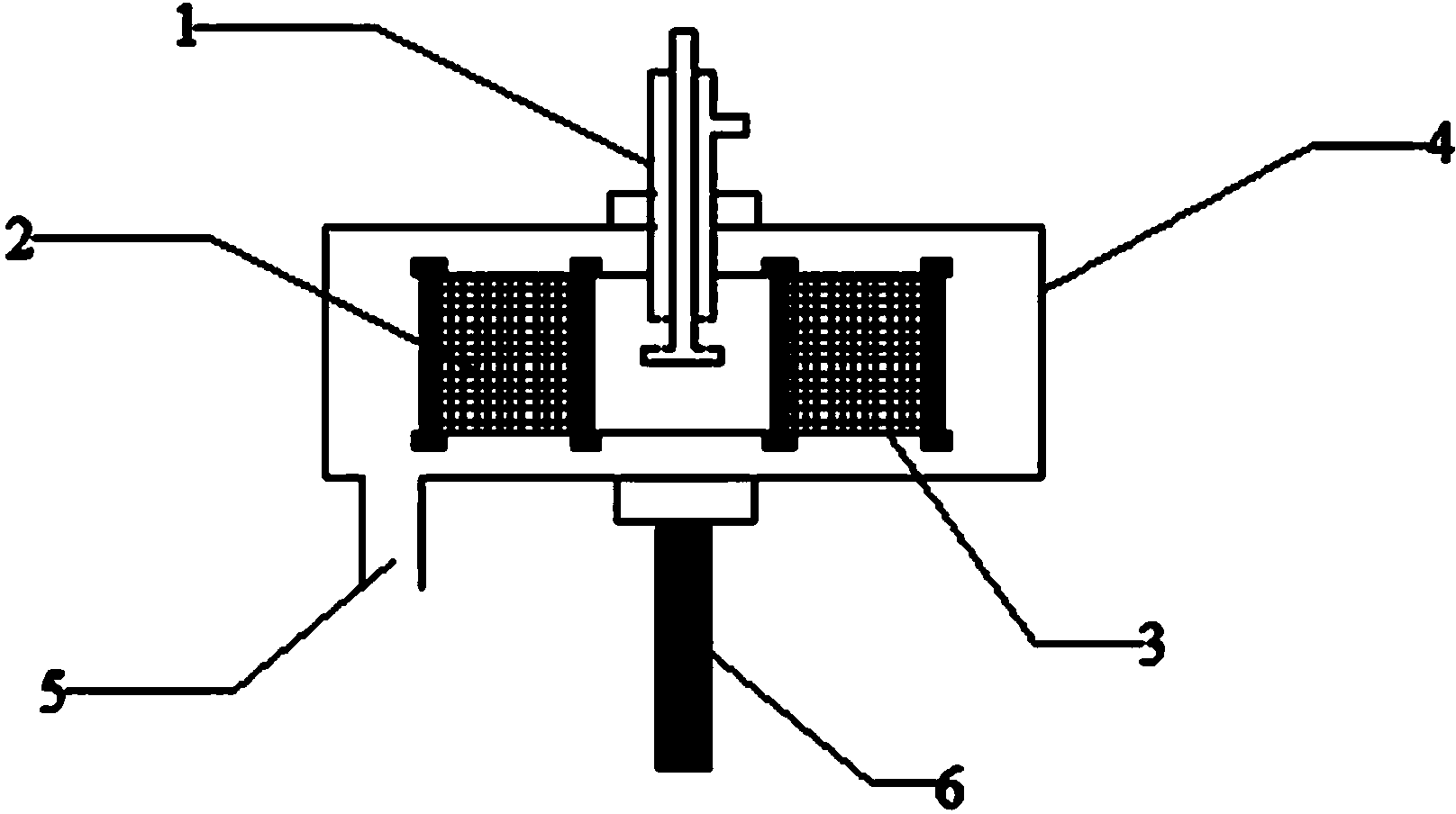

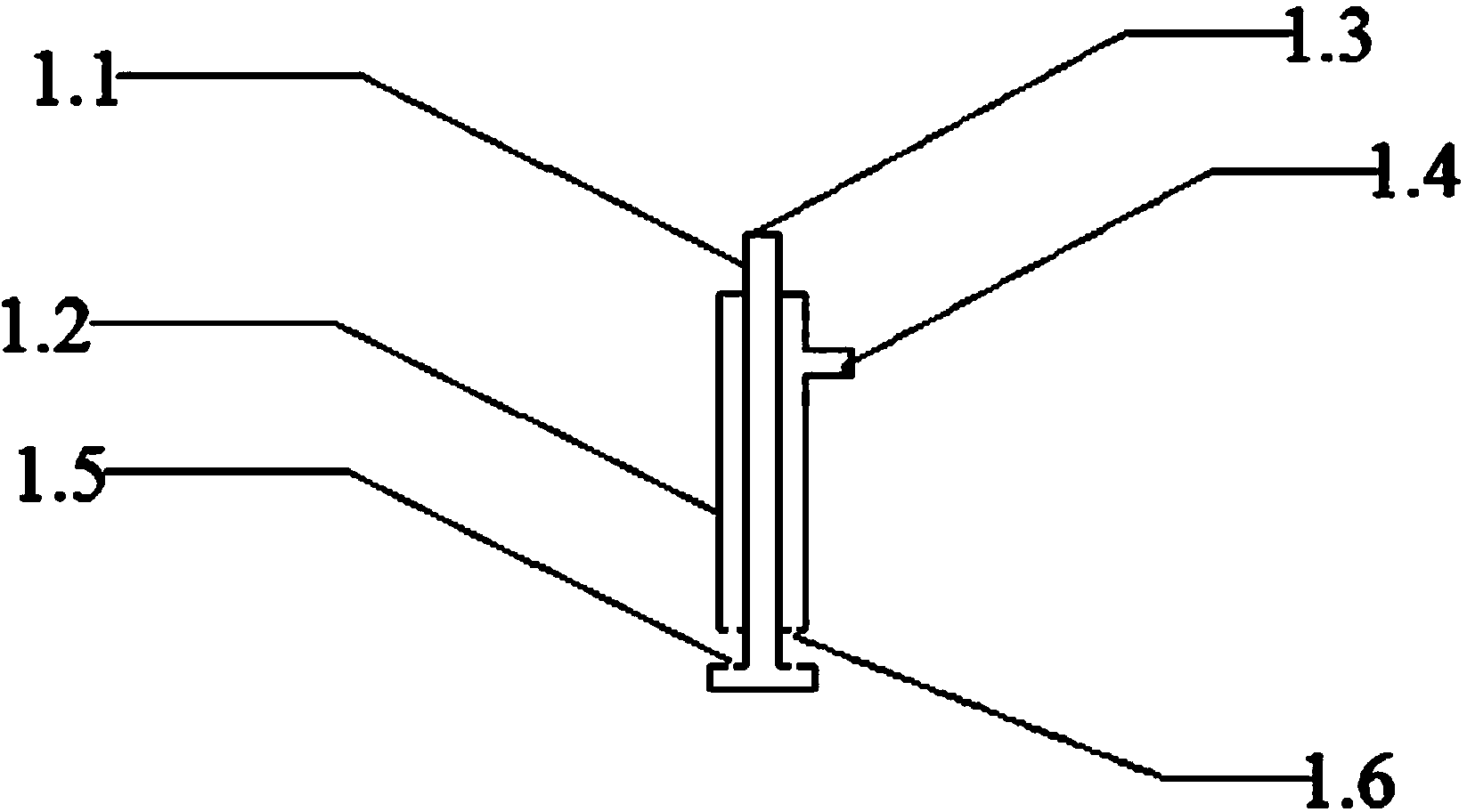

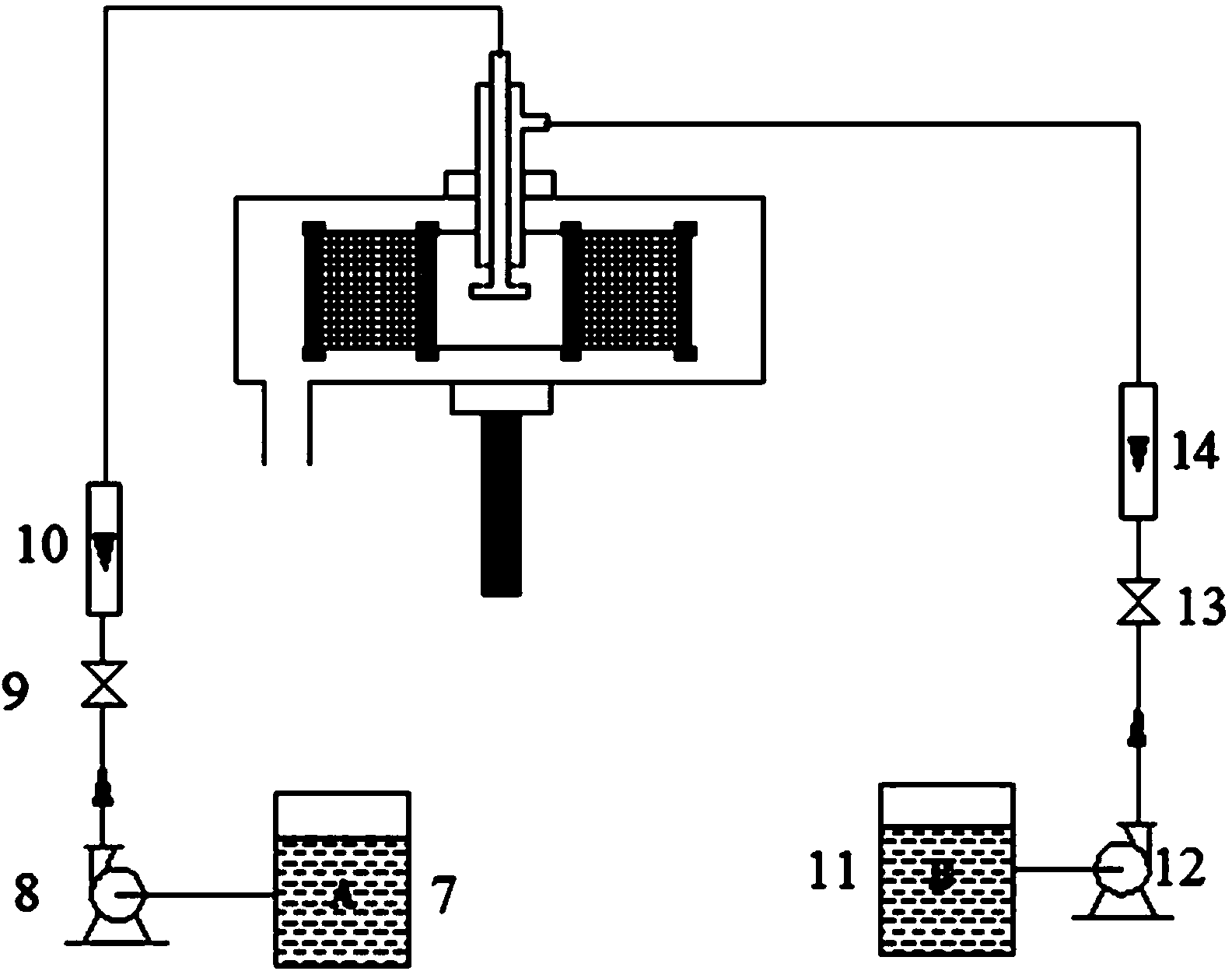

[0031] A new impinging flow-rotating packed bed device is adopted 2 / d 1 =1.5, L 2 / d 2 =10,d 3 / D 1 =6, d 1 / D 1 =10,d 2 / D 1 =20. A, B solution volume flow ratio is 1, d 5 / d 4 =6. Research on diesel emulsification. 0.8000g / mL diesel oil is stored in the storage tank I7, which is solution A, and 3% emulsifier compounded by Tween80 and Span is placed in the storage tank II11, which is solution B, which passes through the pump and flow meter respectively ,, through the first impact of the impact flow in the cavity of the rotor, the formed mixed fluid enters the packing layer 2, and the rotor 3 rotates under the drive of the rotating shaft 6. When the speed is 1200r / min, the strong force generated by the supergravity field Centrifugal force makes the mixed fluid carry out secondary mixing and reaction, and finally enters the liquid outlet 5 and discharges, and the emulsified diesel oil is obtained without stratification for 1 month.

Embodiment 2

[0033] A new impinging flow-rotating packed bed device is adopted 2 / d 1 =10,L 2 / d 2 =30,d 3 / D 1 =1, d 1 / D 1 =100, d 2 / D 2 =2.5. A, B solution volume flow ratio is 5, d 5 / d 4 =2, research on paraffin emulsification. Solution A paraffin is placed in the liquid storage tank 7, and 5% of the emulsifier obtained by compounding Span80, K12 and co-emulsifier A is placed in the liquid storage tank 11, which is solution B. Corrosion pump II12, flowmeter I10, and flowmeter II14 are hit for the first time in the cavity of the hollow annular rotor through the new concussion flow, and the formed mixed fluid enters the packing layer 2, and the hollow annular rotor 3 is in the center of the rotating shaft 6. Driven to rotate, when the rotation speed is 1100r / min, the strong centrifugal force generated by the supergravity field makes the mixed fluid undergo secondary mixing and reaction, and finally enter the liquid outlet 5 and discharge, and the obtained paraffin emulsion ...

Embodiment 3

[0035] A new impinging flow-rotating packed bed device is adopted 2 / d 1 =20,L 2 / d 2 =50,d 3 / D 1 =10,d 1 / D 1 =50,d 2 / D 2 =100. A, B solution volume flow ratio is 20, d 5 / d 4 =2, for the preparation of microemulsion. Put 1mol / L HCl in the liquid storage tank I7, kerosene and 3% Span80 in the liquid storage tank II11, pass through the corrosion-resistant pump I8, corrosion-resistant pump II12, flowmeter I10, and flowmeter II14 respectively to adjust the solution The flow rate of A is 120L / h, and the flow rate of solution B is 80L / h. The passing and impinging flow makes the first impact in the cavity of the hollow annular rotor, and the formed mixed fluid enters the packing layer 2, and the hollow annular rotor 3 Driven by the rotating shaft 6, when the rotation speed is 900r / min, the strong centrifugal force generated by the supergravity field makes the mixed fluid undergo secondary mixing and reaction, and finally enter the liquid outlet 5 and discharge, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com