Method for online laser broadband quenching on surface of steel rail

A rail and laser technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as hardened layer cracking, low equipment efficiency, and inappropriateness, and achieve the effects of prolonging service life, reducing cracks, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

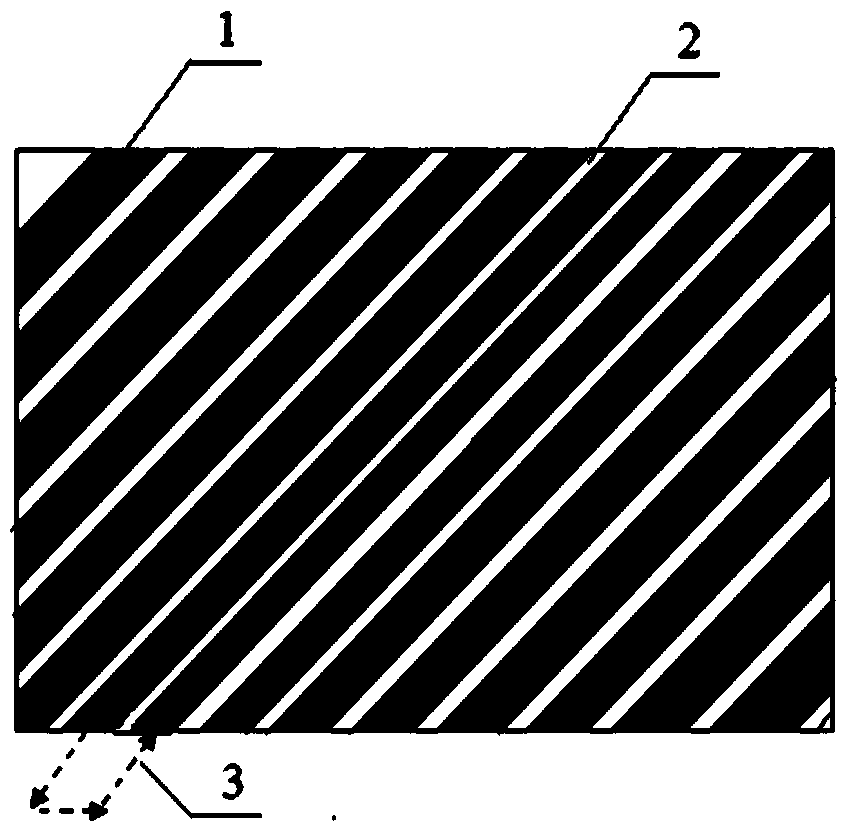

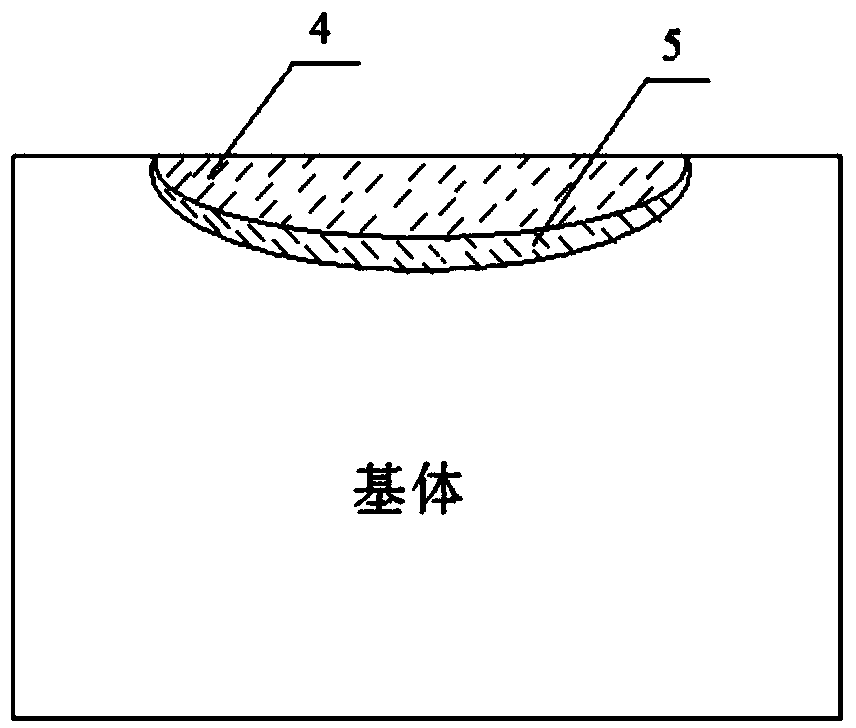

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a method for on-line laser broadband quenching of rail surface, the specific solution is as follows:

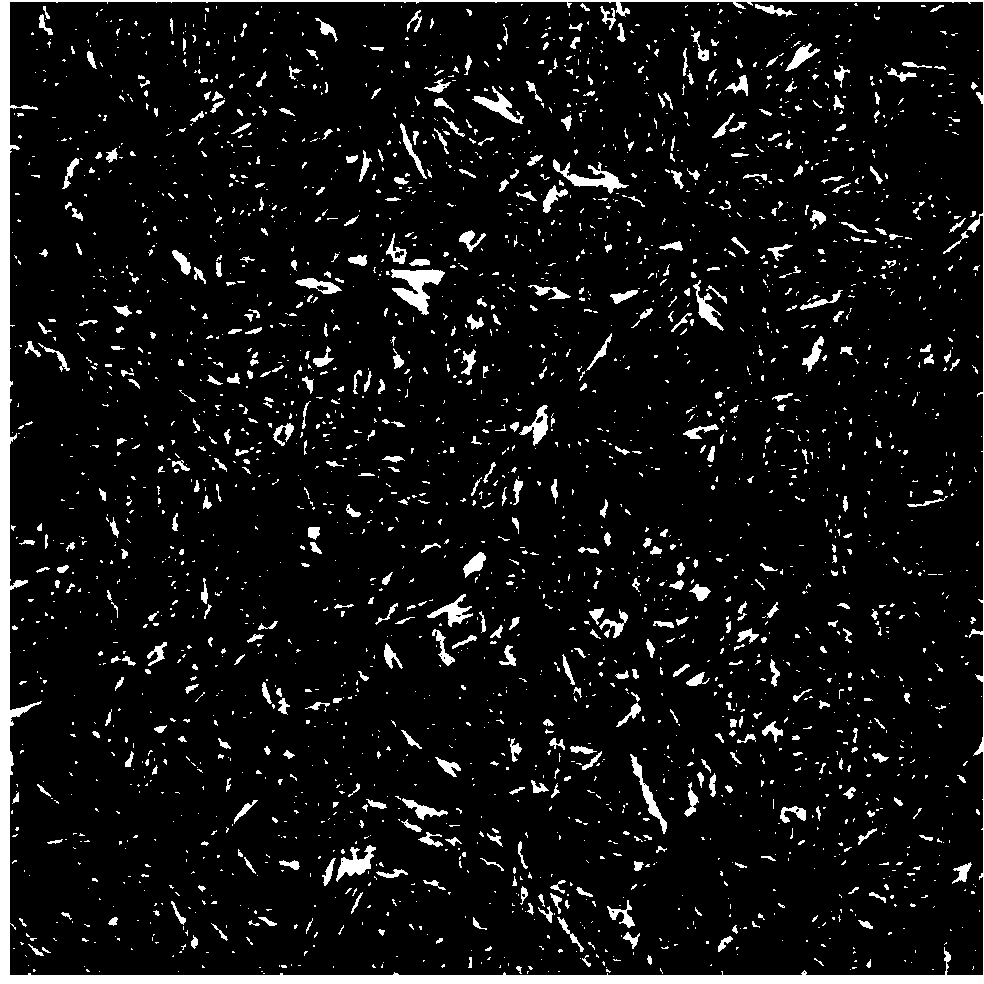

[0020] Fix the laser emitting head of the induction spray gun and the fiber laser on the mechanical arm. First, use the induction spray gun to spray a layer of light-absorbing paint on the surface of the rail. The light-absorbing paint is graphite particles + SiO with a mass fraction of 5%-20%. 2 Particles, the particle size is between 50nm-1um, and then use the fiber laser to quickly scan the wheel-rail contact surface of the rail. The laser power of the fiber laser is 2.5-4.0KW, and the laser quenching spot adopts a rectangular spot with a size of 10mm×2mm or 20mm ×2mm, the scanning speed is 1mm / s-20mm / s, the scanning direction of the laser beam is 45° to the length direction of the rail. The laser hardened layer 4 of the mixed structure of tenite and retained austenite, the thickness of the laser ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com