Construction method and application of over-expressing fusA genetic engineering bacterium

A technology of genetically engineered bacteria and overexpression, applied in the fields of genetic engineering and microbial fermentation, can solve problems such as poor safety, low yield, and high cost, and achieve the effects of reducing the difficulty of separation and purification, reducing production costs, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

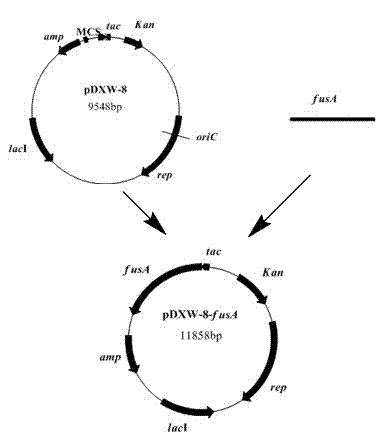

[0025] Example 1 Construction of Elongation Factor EF-G Genetic Engineering Bacteria

[0026] Proceed as follows:

[0027] (1) Design primers for amplification FusA

[0028] Upstream primer: 5'-CTA GCTAGC A GAAGGAGTAA ATCGGTGGCT CAAGAAGTGC TTAAG-3', underlined Nhe I restriction site;

[0029] Downstream primer: 5'-AACC CTCGAG TTAGGAAGCG GTGCCGTTGC-3', underlined as xho I restriction site;

[0030] (2) Use the PCR product and the expression vector pDXW-8 with Nhe I / xho I double digestion, after recovery, the FusA and pDXW-8 at a molar ratio of 6:1 to 3:1, and were ligated with T4 ligase at 16°C for 2 hours to construct the recombinant expression vector pDXW-8- FusA (Such as figure 1 );

[0031] (3) Then the recombinant plasmid pDXW-8- FusA Introduced into Corynebacterium glutamicum WY001, cultured in LBHIS solid medium containing kanamycin (50 μg / mL) for 48 hours at 30° C., and screened for transformants;

[0032] (4) Extract the plasmids of the screened t...

Embodiment 2

[0033] Example 2 Overexpression of EF-G Genetic Engineering Bacteria in Shake Flasks to Produce Amino Acids

[0034] From the deposited strain WY001 / pDXW-8- FusAStretch a ring of bacterial solution in a glycerol tube and streak it on the solid activation medium, and incubate at 30°C for 36 h. Use an inoculation loop to scrape an inoculation loop lawn from the activated plate and transfer it to a 250 mL Erlenmeyer flask containing 25 mL of seed medium, and incubate at 30 °C and 200 rpm for 18 h. Take 2.4 mL of bacterial liquid from the cultured seed liquid and transfer it to a 250 mL Erlenmeyer flask containing 23 mL of fermentation medium. After culturing for 6 h at 30 °C, add a final concentration of 1 mM isopropylthiogalactoside ( IPTG) induced protein expression until the end of fermentation (t=72h).

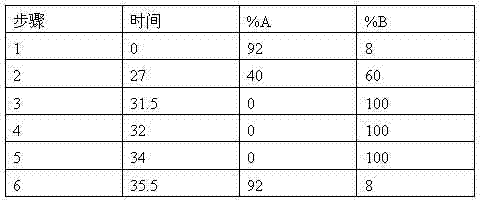

[0035] After the fermentation, the fermented liquid adopts HPLC to measure amino acid content, and utilizes HPLC OPA (o-phthalaldehyde) pre-column derivatization me...

Embodiment 3

[0042] Example 3 Overexpression of EF-G Genetic Engineering Bacteria to Produce Amino Acids in a Fermenter

[0043] From the deposited strain WY001 / pDXW-8- FusA Stretch a ring of bacterial solution in a glycerol tube and streak it on the solid activation medium, and incubate at 30°C for 36 h. Use an inoculation loop to scrape an inoculation loop bacterial lawn from the activated plate and put it into a 500 mL Erlenmeyer flask containing 50 mL of seed medium, and incubate at 30 °C and 200 rpm for 18 h. Transfer 150 mL of seed solution to a 3 L fully automatic fermenter with 1.2 L of fermentation medium. Use 50% ammonia water to automatically adjust pH=7.0, use cooling circulating water and base heating plate to automatically control temperature to 30°C, use stirring speed and dissolved oxygen coupling to maintain dissolved oxygen at 30%, and ventilation rate (1.5 vvm). When cultured for 6 h, protein expression was induced by adding a final concentration of 1 mM IPTG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com