Stainless steel automatic slot shaping device capable of improving efficiency and smoothness

A stainless steel plate, smoothness technology, applied in the direction of planer, metal processing equipment, planer/slotting machine, etc., can solve the problems of collision and scratch on the board surface, low processing accuracy, low processing efficiency, etc., to avoid scratches, guarantee The effect of processing quality and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

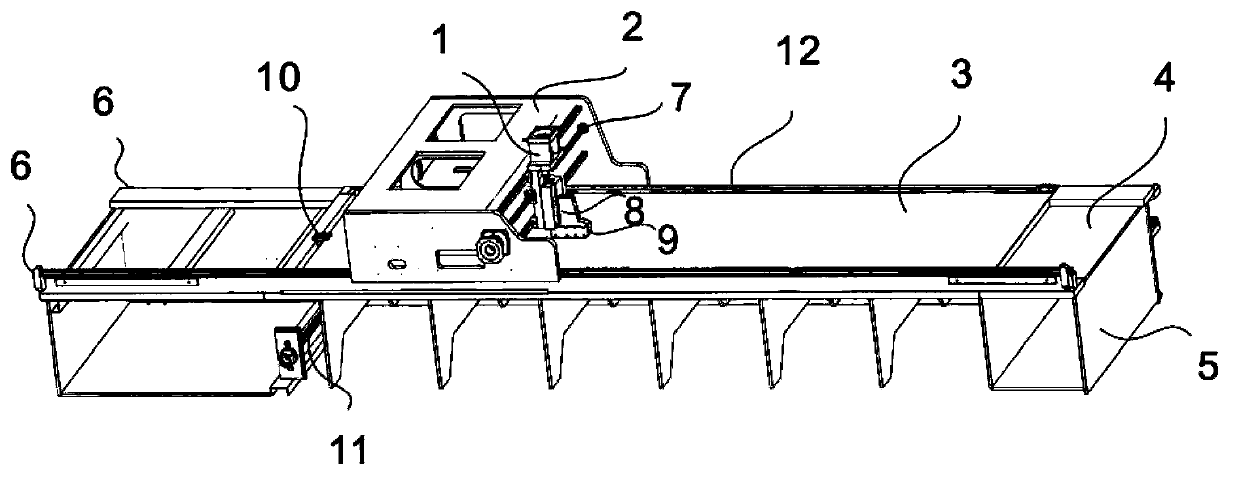

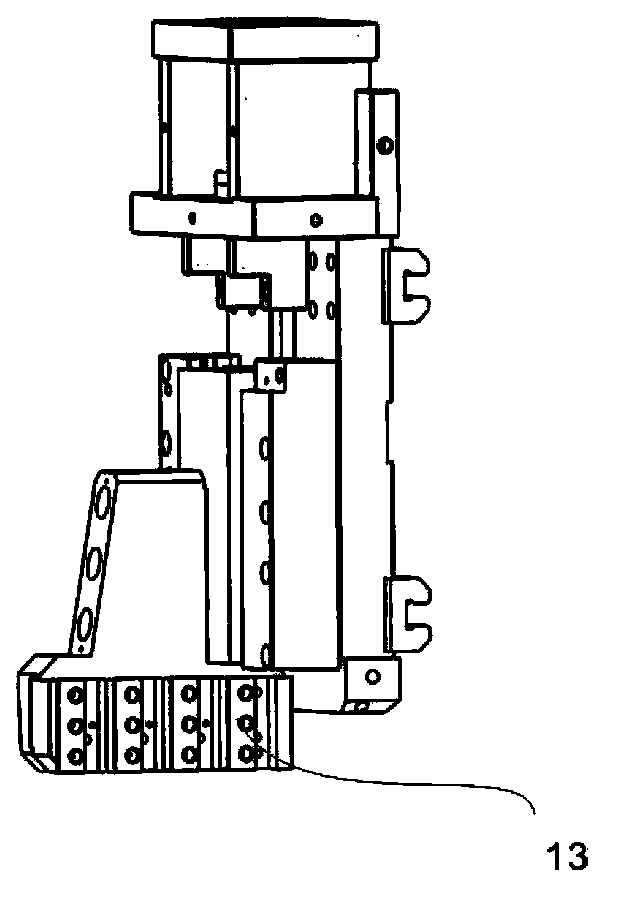

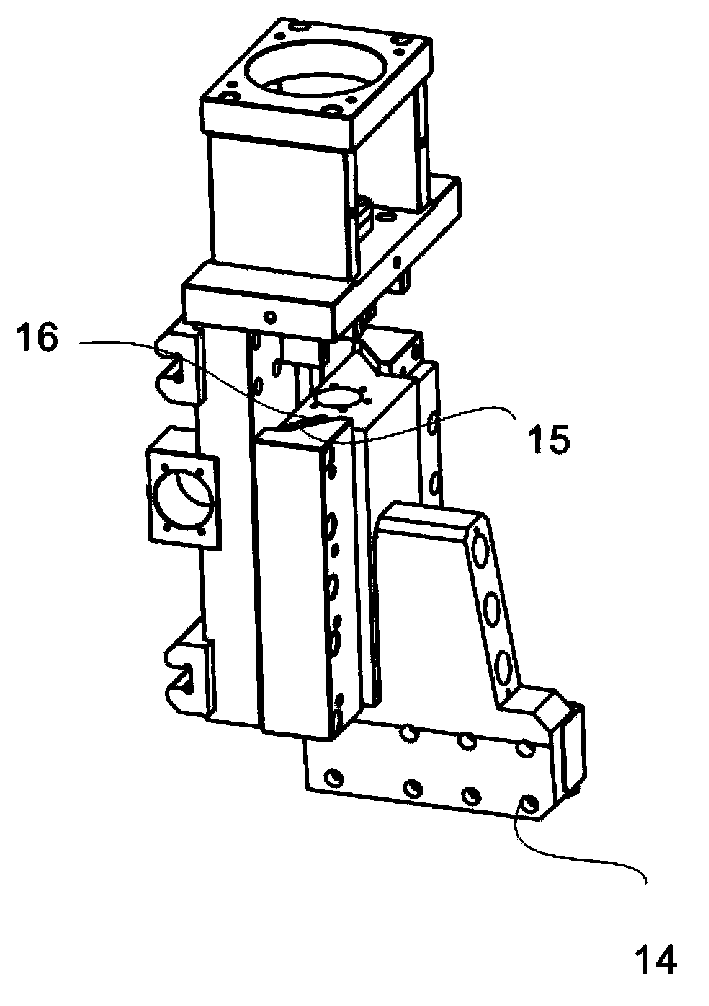

[0016] As shown in the figure, the present invention includes a knife rest 8 and a work frame 5 with a cutter 9, the upper end of the work frame is provided with a work table, the two ends of the work frame are provided with working tracks, and the work tracks are provided with a tool The gantry 2, the tool gantry is connected to the tool holder 1 through the tool holder screw 7, the tool holder is connected to the tool rest with the tool moving up and down through the dovetail groove, and the work table includes the middle workpiece release table 3 and The working stroke table top 4 at both ends, the upper part of the workpiece release table is provided with a workpiece fixing part, and the workpiece fixing part includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com