Base region gradient P<+>-N-N<+> type SiC ultrafast recovery diode manufactured on 4H type single crystal silicon carbide epitaxial layer and process

A technology of single crystal silicon carbide and recovery diodes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

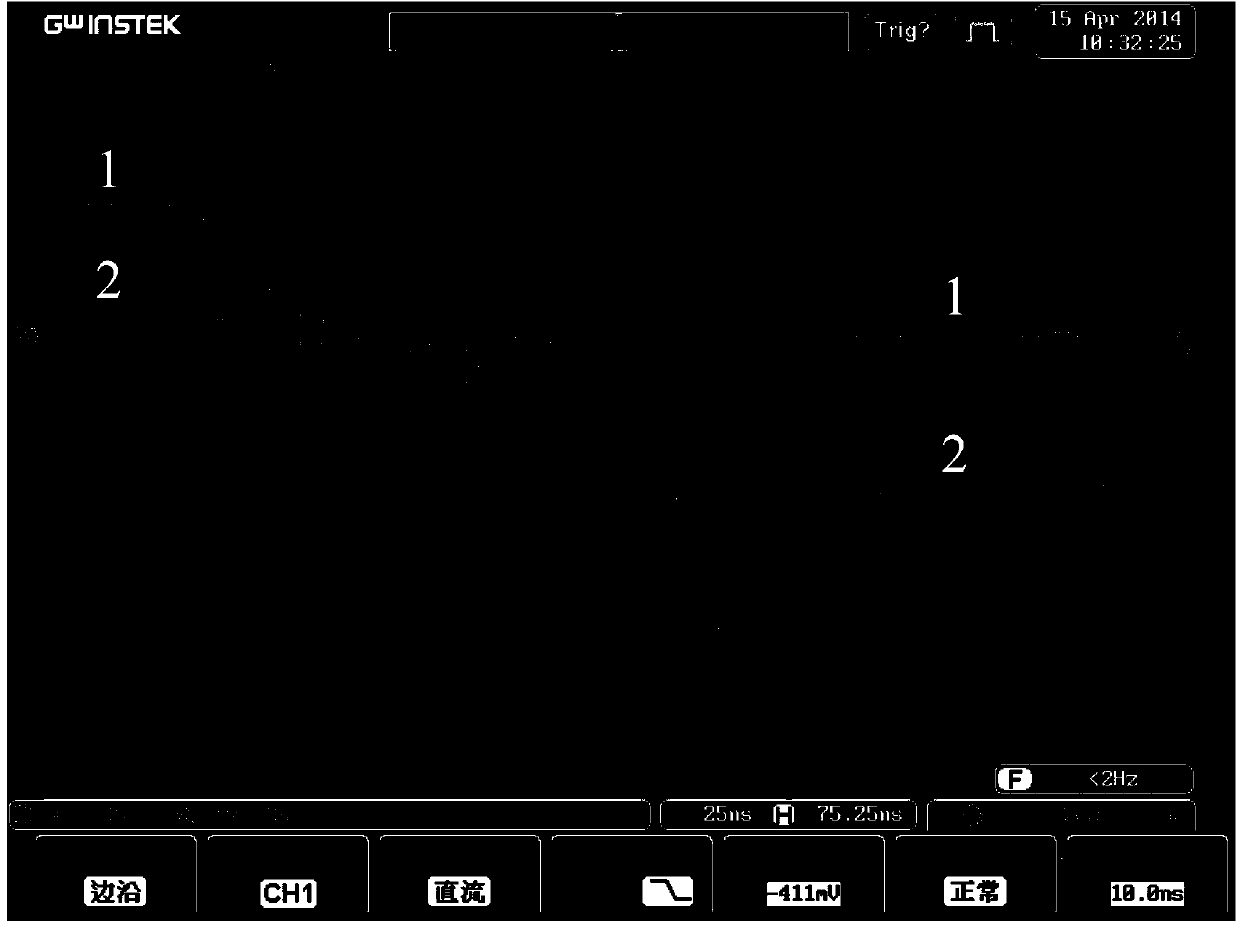

Image

Examples

Embodiment Construction

[0076] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

[0077] Such as figure 1 The specific implementation steps (1) of the present invention shown, select commercial 4H-SiC epitaxial wafers, N + type substrate, the electron concentration is about 1.0×10 19 cm -3 , thickness 250±2 μm, and the N-type epitaxial film on it, the electron concentration is about 1.0×10 17 cm -3 , with a thickness of 10 μm, 8° away from the (0001) plane, and a surface micropipe density lower than 30 μP·cm -2 . Of course, the N of 4H-c-SiC in the present invention + The electron concentration of the substrate can be in the range of 5.0×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com