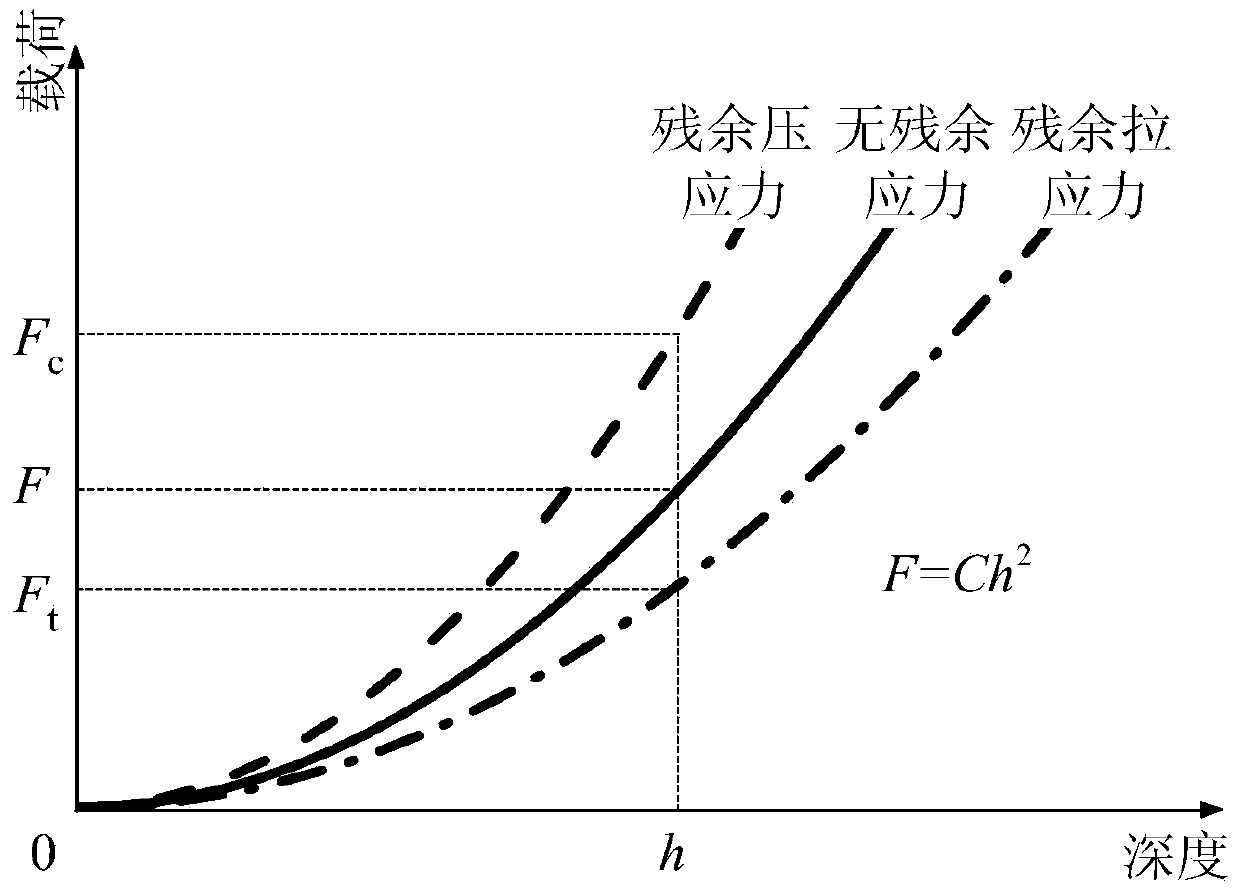

Residual stress detection method based on instrumented indentation technology

A technology of instrumented indentation and residual stress, applied in the direction of instruments, measuring forces, measuring devices, etc., can solve the problems of poor reliability and low accuracy, and achieve the effect of high accuracy and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

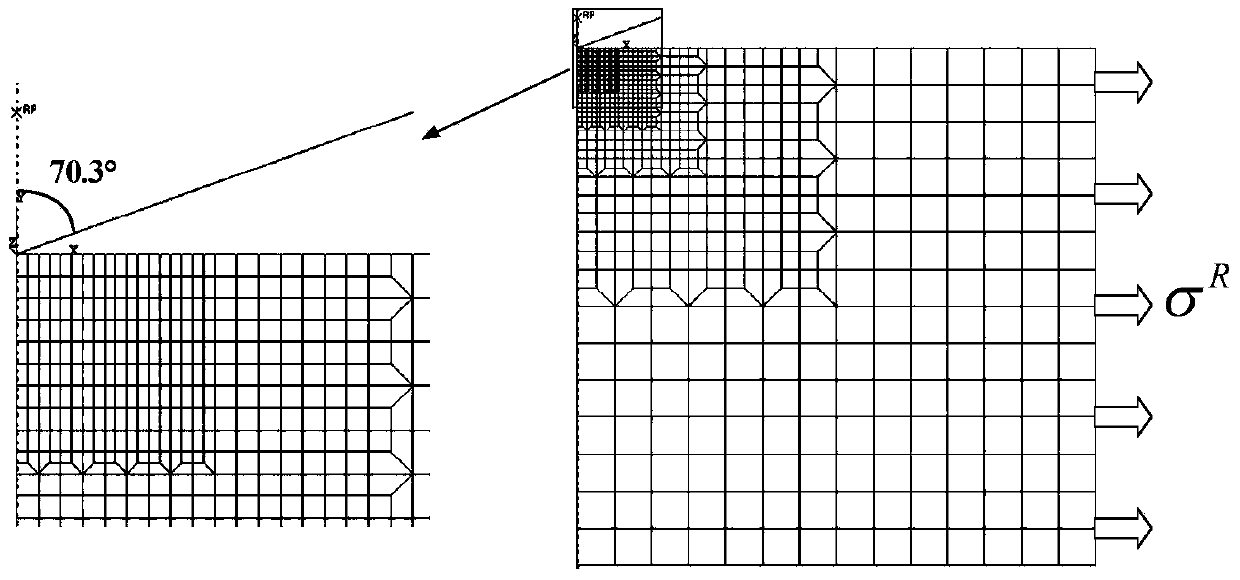

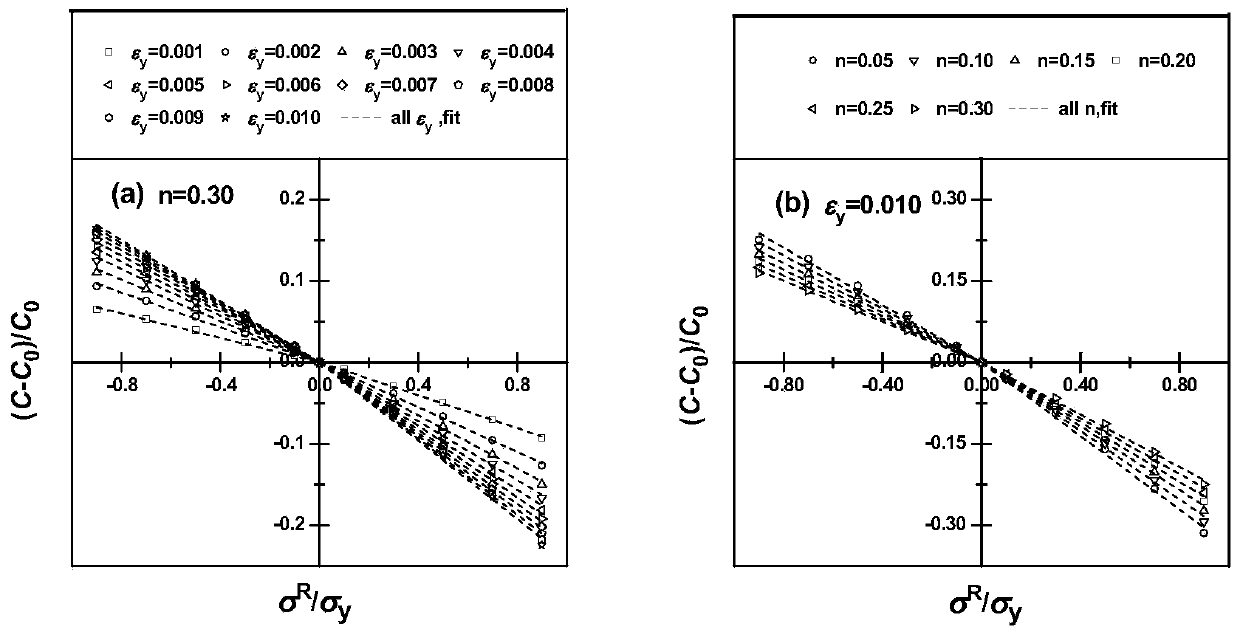

Method used

Image

Examples

example

[0060] Example: Four typical metals (Al 2024, Al 7075, Copper C11000 and Ti Grade5) were selected as experimental materials to verify the reliability of the residual strain detection method.

[0061] In the first step, the uniaxial tensile test is carried out on the four kinds of metal materials through the material testing machine MTS810, and the elastic modulus E and yield strength σ are measured y , Yield strain ε y and power hardening exponent n, see Table 1.

[0062]

[0063] Table 1

[0064] In the second step, since the four metal materials have no residual stress, the residual stress is equivalent to the residual stress by applying prestress to the sample without residual stress, and the applied prestress value is the nominal residual stress. Prepare 5 samples for each material, of which 2 are prestressed, 2 are prestressed, and 1 is not prestressed (as a reference sample). The size of prestressed (namely nominal residual stress) is shown in Table 2 . On the Zw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com