Aquatic vegetable fat-cellulose acetate composite semi-permeable membrane bionic passive sampling device

A technology of external device and water body, which is applied in the customs technology, can solve the problems of restricting the application of aquatic plants, large species differences, poor reproducibility, etc., and achieve the effects of shortening the equilibrium time, enhancing hydrophilicity, and low-cost monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Production of preparation tools for aquatic vegetable fat-cellulose acetate composite semi-permeable membrane

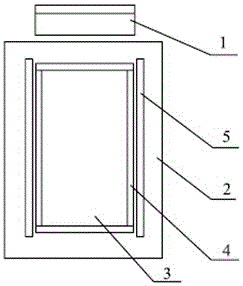

[0041] figure 1 It is a structural representation of the preparation tool in the present invention, as shown in the figure:

[0042] (1) Using a smooth tempered glass plate 2 as the base, four thin tempered glass strips 4 with a width of 5 mm and a thickness of 50-200 μm are used on the upper surface of the tempered glass plate 2, and the length is 15 cm. , a rectangular parallelepiped glass groove 3 with a width of 12 cm and a depth of 50-200 μm, and adjust the depth of the glass groove 3 according to the thickness of the semi-permeable membrane required in practice;

[0043] (2) The scraper 1 required for the preparation of the semi-permeable membrane was developed using toughened glass or metal materials with a certain weight. The scraper 1 was in the shape of a cuboid. The width of the scraper 1 was 12 cm, the height was 5-10 cm, and the thickn...

Embodiment 2

[0045] Example 2 Preparation of aquatic vegetable fat-cellulose acetate composite semipermeable membrane

[0046] Weigh cellulose acetate, cis-9,12-octadeca-dienoic acid, anhydrous magnesium perchlorate, acetone and 1,4-dienoic acid in a mass ratio of 9:1:1:40:5 For oxygen hexane, stir and mix the various materials and put them into an ultrasonic cleaner to vibrate for 1 hour, and then vibrate at a constant temperature of 100 rpm at 25 °C for no less than 24 hours until the casting solution is evenly mixed. At this time, the casting The membrane solution is clear without any air bubbles and solid impurities. Take out a small amount of mixed raw material and pour it into the rectangular parallelepiped glass groove 3 on the tempered glass plate 2, so that it is evenly dispersed into long strips with a width of 1-2 cm. Put the scraper 1 between the left and right tempered glass retaining grooves 5, put the wedge-shaped lower edge of the scraper 1 against the top of the glass gro...

Embodiment 3

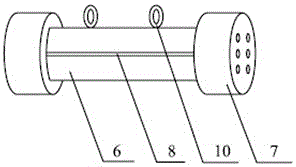

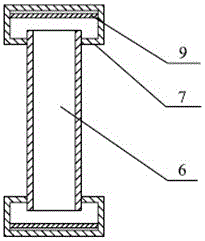

[0047] Example 3 Production of supporting external devices suitable for in-situ sampling of organic pollutants in lakes, rivers and other water bodies

[0048] figure 2 It is a structural schematic diagram of the matching external device in the present invention, image 3 It is a longitudinal sectional view of the matching external device in the present invention, combined with figure 2 , image 3 As shown, the matching external device includes a stainless steel cylinder 6 and screw caps 7 at both ends. The screw cap 7 and the stainless steel cylinder 6 are threaded. There are small holes on the screw cap 7, and a stainless steel mesh 9 is welded on the inside. The mesh 9 has a pore size of 75-150 μm, which facilitates the inflow of water and prevents disturbances such as organisms and particles. The stainless steel cylinder 6 is evenly divided into two halves longitudinally, and an aquatic vegetable fat-cellulose acetate composite semi-permeable membrane 8 is placed betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com