Flow equalization structure for air inlet of heat exchanger plate beam

A gas inlet and heat exchanger technology, which is applied to heat exchange equipment, heat exchanger shells, lighting and heating equipment, etc., can solve the problems of large gas energy loss, high equipment operating costs, and equipment shutdown, etc. Economical, simple structure, convenient processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

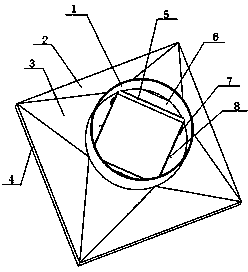

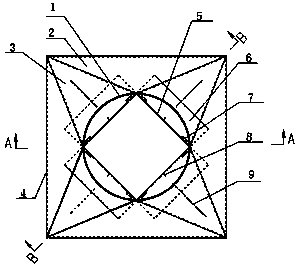

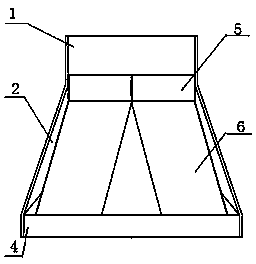

[0024] The present invention and its beneficial effects will be further described below in conjunction with the accompanying drawings.

[0025] refer to Figure 1 to Figure 5 Shown: a flow equalization structure for the gas inlet of the heat exchanger plate bundle, the shell of the present invention is composed of a cylinder 1, a round sky 2, and a square box 4, and an open diffuser 10 is installed in the shell . Wherein the open expander 10 is made up of a diversion section 5 and a diversion section 6 at a certain angle, the diversion section 5 is composed of several preferably 4 diversion plates with the same shape and size, and the diversion section 6 is composed of Several pieces preferably consist of 4 baffles with the same shape and size. Both the deflector and the deflector are rectangular or square thin steel plates.

[0026] The angle between the diversion section 5 and the diversion section 6 of the open diffuser 10 can be adjusted by an angle adjustment device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com