Intelligent double-vortex-tube refrigerating and heating system

A cooling and heating, double eddy current technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of cabinet influence, unstable airflow temperature, large amount of compressed air, etc., to improve the level of energy saving and reduce the overall The effect of consumption and utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

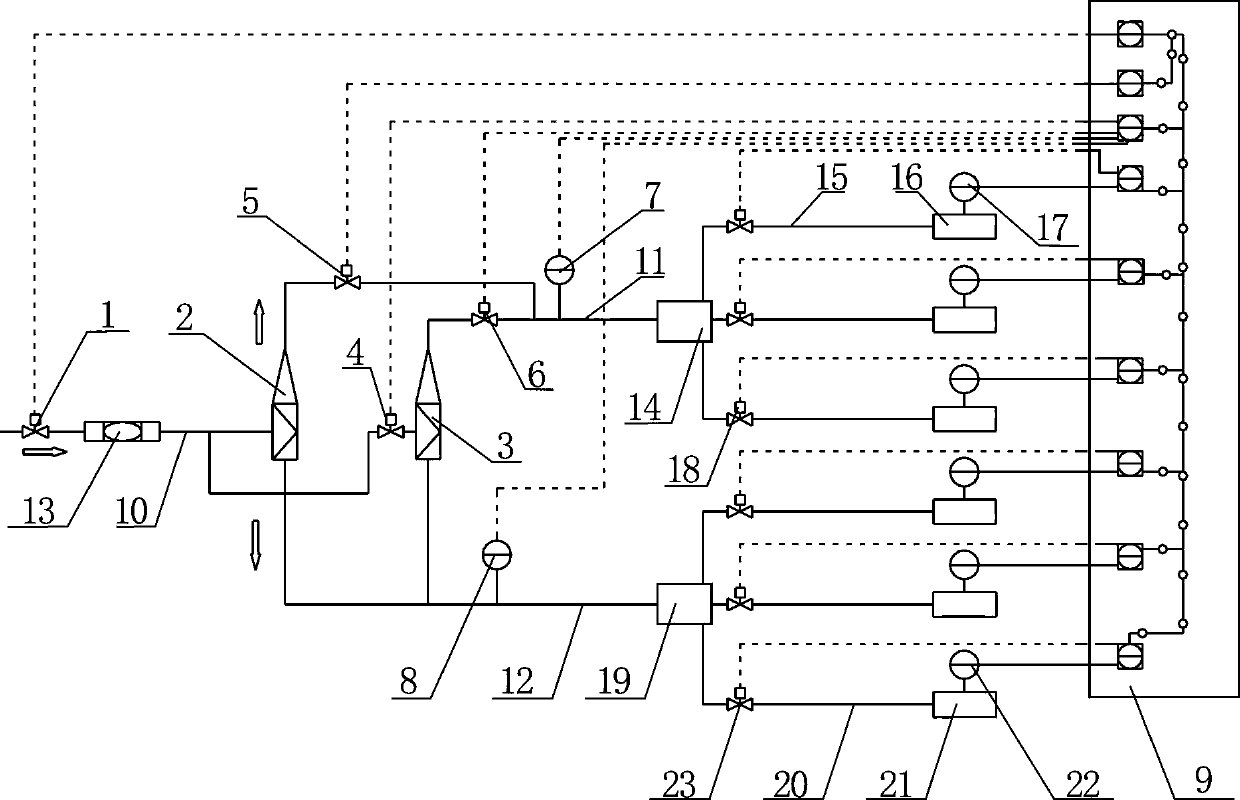

[0017] Such as figure 1 As shown, the intelligent double vortex tube cooling and heating system is mainly composed of flow regulating valve 1, main vortex tube 2, auxiliary vortex tube 3, intake valve 4, main cooling coefficient control valve 5, auxiliary cooling coefficient control valve 6, heating An airflow temperature sensor 7, a cold airflow temperature sensor 8 and a controller 9 are formed. The main vortex tube 2 and the auxiliary vortex tube 3 are installed in parallel. In the main vortex tube 2 and the auxiliary vortex tube 3, the compressed air input ends are connected to the same Intake pipeline 10, the output end of hot air flow is connected to the same hot air pipeline 11, the output end of cold air flow is connected to the same cold air pipeline 12, the flow regulating valve 1 is arranged on the air intake pipeline 10, and the air intake valve 4 Set at the compressed air input end in the auxiliary vortex tube 3, the main cooling coefficient control valve 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com