A pdc drill tool with alternating cutting trajectories

A technology of variable cutting and drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc. It can solve the problems that rock breaking cannot be achieved, and achieve the goal of improving self-sharpening and attack ability, increasing eating ability, and improving eating ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

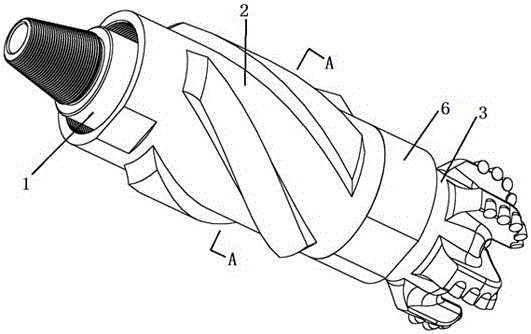

[0057] Such as Figures 1 to 9 As shown, the PDC bit tool with alternating cutting tracks of the present invention is composed of an eccentric shaft 1, an outer shell 2, a PDC bit 3, a cycloidal shaft 4, a needle tooth group 5, and a lower joint 6. The needle tooth group 5 consists of several Pintooth pin 51 and pintooth sleeve 52 are formed. in:

[0058] Such as Figure 5 As shown, one end of the eccentric shaft 1 is provided with a connecting thread 11, and the middle part is provided with a positioning shoulder 13, and the center distance between the geometric center of the eccentric shaft section 12 and the geometric center of the eccentric shaft body is e.

[0059] Such as Figure 6 As shown, the upper and lower ends of the outer casing 2 are respectively provided with connecting threads 22 and 23 . Gauge corrugations 21 are arranged on the outer cylindrical surface, and the gauge corrugations 21 can be in a straight structure or in a spiral structure, and the number ...

Embodiment 2

[0068] Such as Figure 10 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that passive wear-resistant teeth 211 or active cutting teeth 212 are fixed on the gage flute 21, or passive wear-resistant teeth 211 and active cutting teeth are fixed at the same time. 212.

[0069] Under the ideal drilling conditions of the conventional PDC bit (the "ideal drilling condition" here refers to the working state in which the center of rotation of the bit coincides or nearly coincides with the center of the wellbore trajectory during the process of drilling and breaking the PDC bit), the cutting teeth rotate in one revolution cycle. The cutting amount and cutting load in the drill bit do not change much, so its mechanical stability is good (under ideal drilling conditions, the ratio of lateral unbalanced force to axial force of most PDC drill bits can be controlled within 5% level).

[0070]However, in this embodiment, the PDC bit performs alternatin...

Embodiment 3

[0073] Such as Figure 11 As shown, this embodiment is basically the same as Embodiment 2, and the difference is that three or more rows of needle holders 24 are vertically arranged on the inner cylindrical surface of the outer shell 2 in the axial direction.

[0074] In this embodiment, since the PDC bit is directly connected with the cycloid shaft, the loads it bears include axial pressure, torque, and bending moment, etc., especially in hard formations or heterogeneous formations, the instantaneous Shock loads are very high. Therefore, in this embodiment, the radial load fluctuation of the meshing force between the cycloidal shaft and the pin-tooth group is relatively large, and the distribution of the axial load is also very uneven. In order to improve the stability and reliability of the pin-tooth in meshing transmission, There are three or more rows of needle holders, which are used to support the needle pins and needle sleeves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com