Efficient drilling system and method for bottom-hole punching, swirling and stepping combined unloading and rock breaking

A rock-breaking and swirling technology, which is applied in the direction of drilling drive devices, drilling equipment, drill bits, etc. in the wellbore, can solve problems such as failure to meet the expected indicators on site, and achieve the effect of increasing service life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

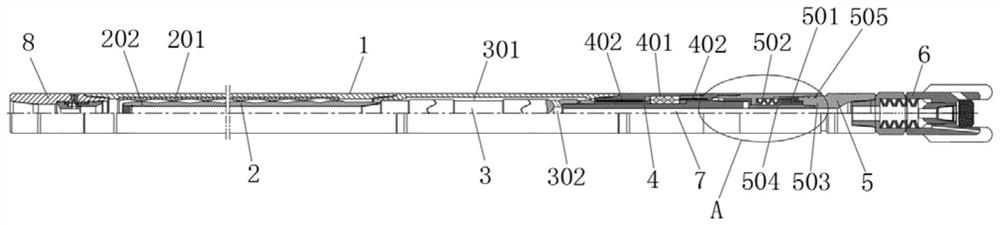

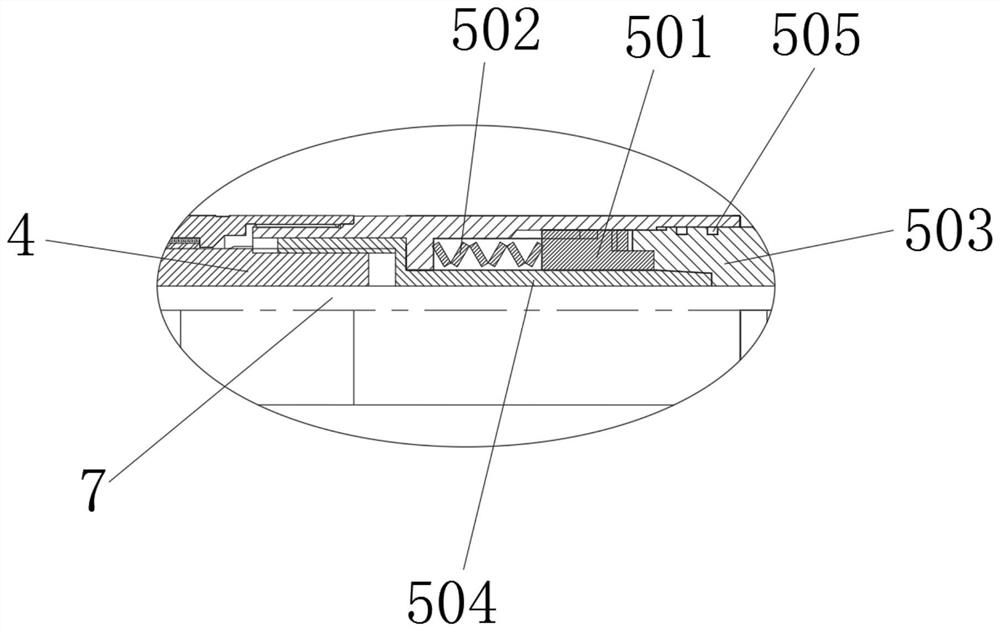

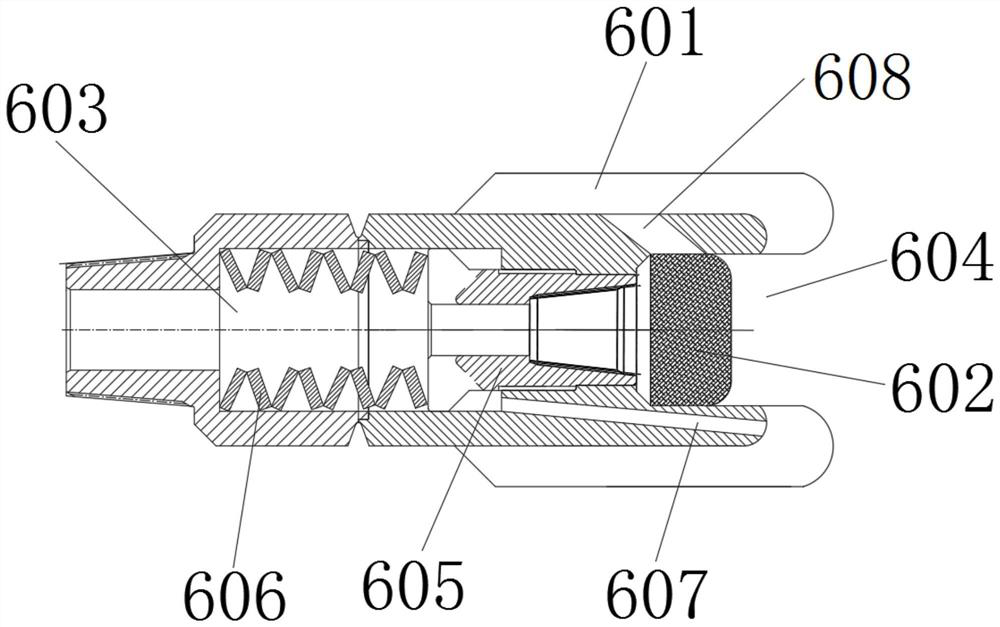

[0065] like figure 1 As shown in the figure, the bottom-hole rush-rotation step combined unloading and rock-breaking high-efficiency drilling system includes a casing 1 in a cylindrical structure; the casing 1 is provided with a drive assembly 2, a cardan shaft that are connected in sequence along the axial direction. Section 3, transmission shaft 4, rotary impact assembly 5; the end of the rotary impact assembly 5 is provided with a drill bit 6; wherein the rotational power of the drive assembly 2 is transmitted to the transmission shaft 4 through the universal joint 3, and the transmission shaft 4 Then, the rotating power is transmitted to the rotating impact assembly 5, and the rotating impact assembly 5 transmits the rotating power to the drill bit 6; at the same time, in the actual production process, the casing 1 can be designed and produced in sections according to the actual situation, so as to facilitate the drive assembly 2 , the installation of universal joint 3, tr...

Embodiment 2

[0104] A high-efficiency drilling method for rock-breaking with bottom-hole swirl-stepping combined unloading and rock-breaking is implemented based on the high-efficiency drilling system for bottom-hole swash-rotating stepping combined with unloading and rock-breaking in Embodiment 1, and the drilling method includes the following steps:

[0105] 1) Pump the drilling fluid into the drive assembly 2, and the pressure energy of the drilling fluid is converted into the rotational mechanical energy of the rotor 202, which is transmitted to the drill bit 6 by the universal joint 3, the transmission shaft 4, and the rotary transmission assembly;

[0106] 2) The annular drill bit 601 first contacts the bottom of the well, and under the action of the weight-on-bit torque, the rock at the outer ring of the drill bit 6 is broken; during the rotation of the rotary transmission assembly, under the action of the bottom-hole reverse push force, the impact assembly The high-frequency impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com