Drilling tool for stimulating vibration of drill column

A technology for drilling tools and drill strings, which is applied in the field of drilling tools that excite drill string vibrations, and can solve the problems of being difficult to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following are specific examples of the drilling tool for stimulating drill string vibration of the present invention, which are used to explain but not limit the present invention.

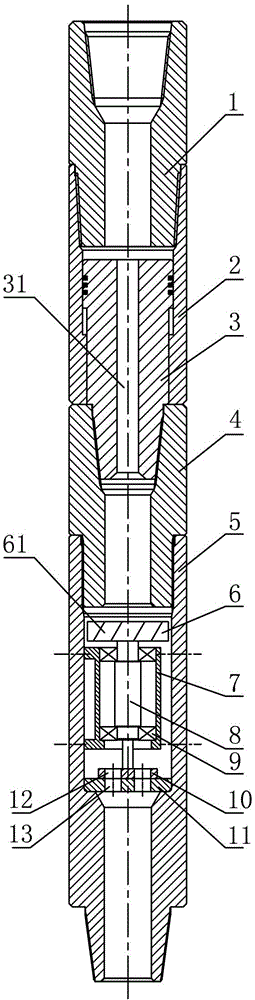

[0014] As shown in the accompanying drawings, a drilling tool that excites the vibration of the drill string includes: a cylindrical upper shell 2, an adapter 1 is installed on the upper end of the upper shell 2, and the adapter 1 is located in the upper shell 2 A piston rod 3 is slidingly arranged below the upper housing 2, wherein the matching through hole at the lower end of the upper housing 2 and the matching section in the middle of the piston rod 3 are processed into a polygonal shape, the lower end of the piston rod 3 protrudes from the lower end of the upper housing 2, and the upper end of the piston rod 3 A hollow piston rod flow channel 31 extending along its axial direction is provided; a cylindrical lower housing 5 is provided with an intermediate joint 4 between the lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com