Bit pup joint capable of producing hydraulic pulsation in downhole

A technology of drill bits and pup joints, which is applied in drilling tools, drilling equipment, earthwork drilling, etc., can solve the problems of limiting rock-breaking drilling efficiency, weakening hydraulic pulsation auxiliary rock-breaking ability, and large loss of hydraulic energy along the way, to achieve The Effect of Improving the Drilling Efficiency of Drill Bits in Breaking Rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

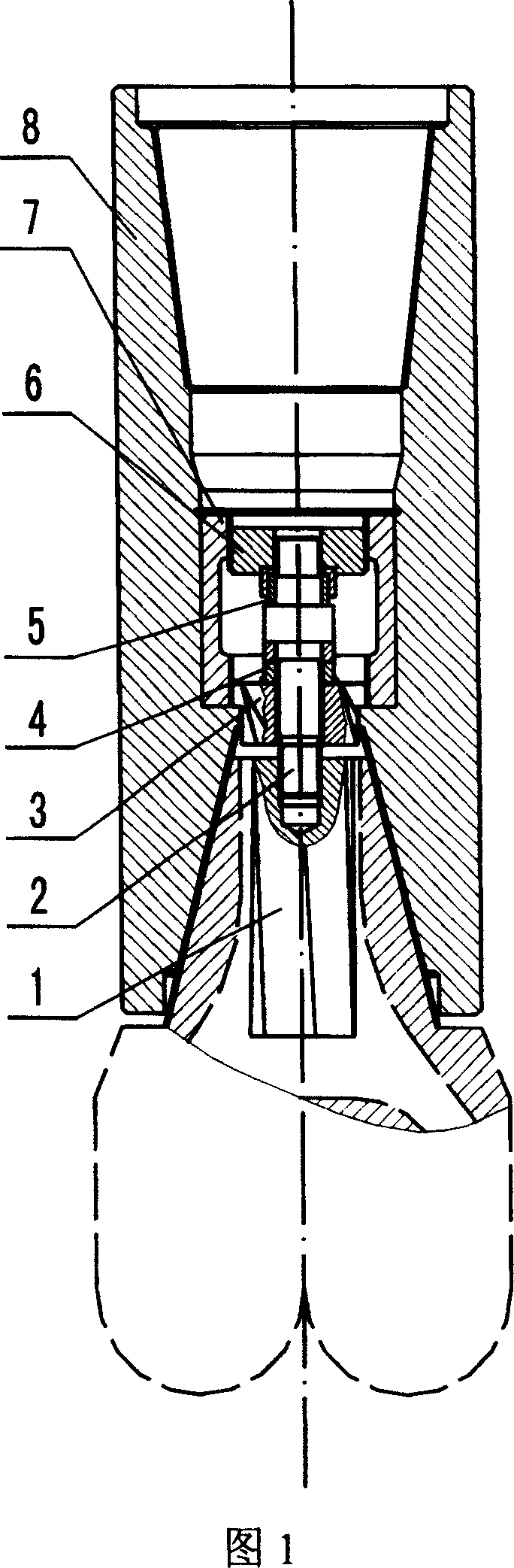

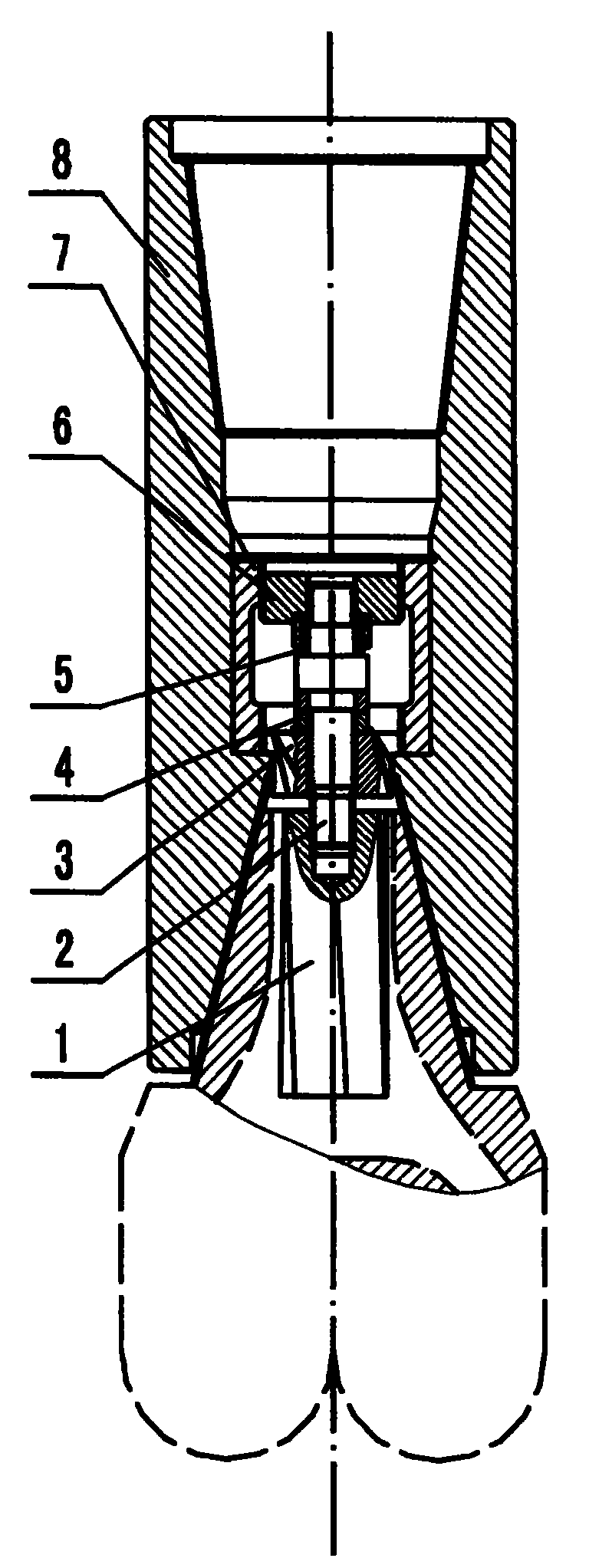

[0008] Now in conjunction with further description of the present invention.

[0009] When adopting the present invention to break formation rocks, the rotor is installed on the lower end of the connecting shaft by screw connection. The stator is sleeved on the connecting shaft and installed on the upper part of the rotor. There is a gap between the inner diameter of the stator and the outer diameter of the connecting shaft. The stator and the connecting sleeve are connected by threads. A thrust bearing is installed between the stator and the shoulder of the connecting shaft. A compression nut is arranged on the upper end of the connecting shaft, a centralizing bearing is arranged between the compression nut and the shaft shoulder of the connecting shaft, and a threaded connection is adopted between the compression nut and the connecting sleeve. The connection sleeve is fixed inside the pup joint housing. The hydraulic pulsation drill bit nipple is connected with the drill b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com