Preparation method of photo-cured durable liquid-crystal thermochromic garment material

A thermochromic and light-curing technology, applied in microsphere preparation, microcapsule preparation, fiber treatment, etc., can solve the problems of liquid crystal pollution, increase the burden on enterprises, consume a lot of energy, etc., and achieve good washing fastness and wear resistance. , good social benefits, the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 30mL of 10g / L gelatin and 10g / L gum arabic at 40°C, add 20mL of 5g / L core material to mix liquid crystal dichloromethane solution, and shear at 10000r / min for 5 minutes to obtain a dispersed emulsion; Move the phase into a three-neck flask, adjust the pH to 4 with 10% acetic acid solution, stir for 30 minutes, cool the ice water to below 5°C, add 37% formaldehyde solution equal to the amount of gelatin, and continue stirring for 30 minutes to make the microcapsules The wall solidified and hardened, and 10% sodium hydroxide solution was added to adjust the pH value to 9, and the stirring was continued for 2 hours to slowly raise the solution to room temperature; finally, suction filtration was performed to obtain liquid crystal microcapsules. (The mixed liquid crystal is cholesteryl pelargonate (CPE) and cholesteryl oleyl carbonate (COC), the ratio of which is 40:60).

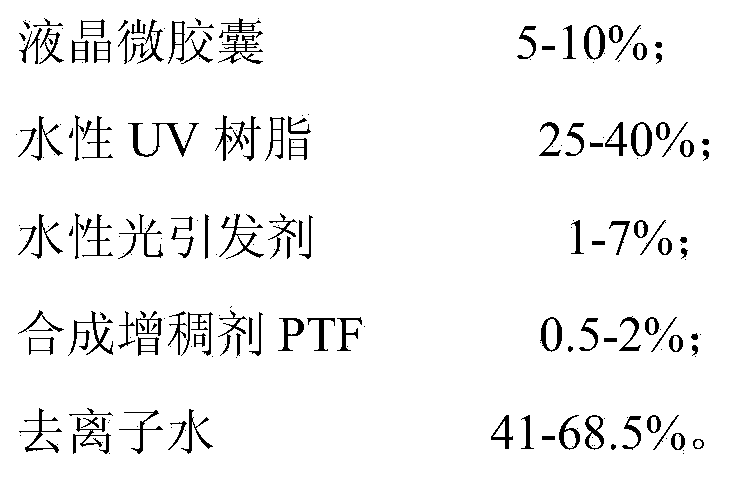

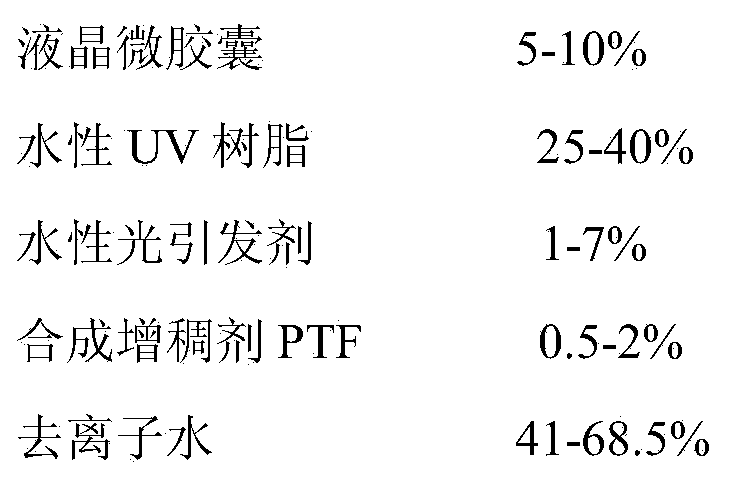

[0026] Prepare coating paste. The raw material components are: 10g of liquid crystal microcapsule...

Embodiment 2

[0030] Mix 30mL of 10g / L gelatin and 10g / L gum arabic at 40°C, add 20mL of 5g / L core material to mix liquid crystal dichloromethane solution, and shear at 20000r / min for 10 minutes to obtain a dispersed emulsion; Move the phase into a three-neck flask, adjust the pH to 4 with 10% acetic acid solution, stir for 30 minutes, cool the ice water to below 5°C, add 37% formaldehyde solution equal to the amount of gelatin, and continue stirring for 30 minutes to make the microcapsules The wall solidified and hardened, and 10% sodium hydroxide solution was added to adjust the pH value to 9, and the stirring was continued for 2 hours to slowly raise the solution to room temperature; finally, suction filtration was performed to obtain liquid crystal microcapsules. (wherein said mixed liquid crystal is cholesteryl pelargonate (CPE), cholesteryl chloride (CC), cholesterol carbonate (DCC), cholestenyl p-nonylphenyl carbonate (CNPC), and its ratio is 45: 10:15:30).

[0031] Prepare coating ...

Embodiment 3

[0035] Mix 30mL of 10g / L gelatin and 10g / L gum arabic at 40°C, add 20mL of 5g / L core material to mix liquid crystal dichloromethane solution, and shear at 15000r / min for 7 minutes to obtain a dispersed emulsion; Move the phase into a three-neck flask, adjust the pH to 4 with 10% acetic acid solution, stir for 30 minutes, cool the ice water to below 5°C, add 37% formaldehyde solution equal to the amount of gelatin, and continue stirring for 30 minutes to make the microcapsules The wall solidified and hardened, and 10% sodium hydroxide solution was added to adjust the pH value to 9, and the stirring was continued for 2 hours to slowly raise the solution to room temperature; finally, suction filtration was performed to obtain liquid crystal microcapsules. (wherein the mixed liquid crystal is cholesteryl pelargonate (CPE), cholesteryl benzoate (CBZ), cholesteryl carbonate (DCC), cholestenyl p-nonylphenyl carbonate (CNPC), and its ratio is 36.8:15.1:19.2:28.9).

[0036]Prepare coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com