Nanometer blocking agent for oil-based drilling fluid and preparation method of nanometer blocking agent

A nano-plugging agent and oil-based drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of easy collapse of the well wall of shale gas wells, and achieve the reduction of API filtration loss and operation. The process is simple and the effect of solving the collapse of the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

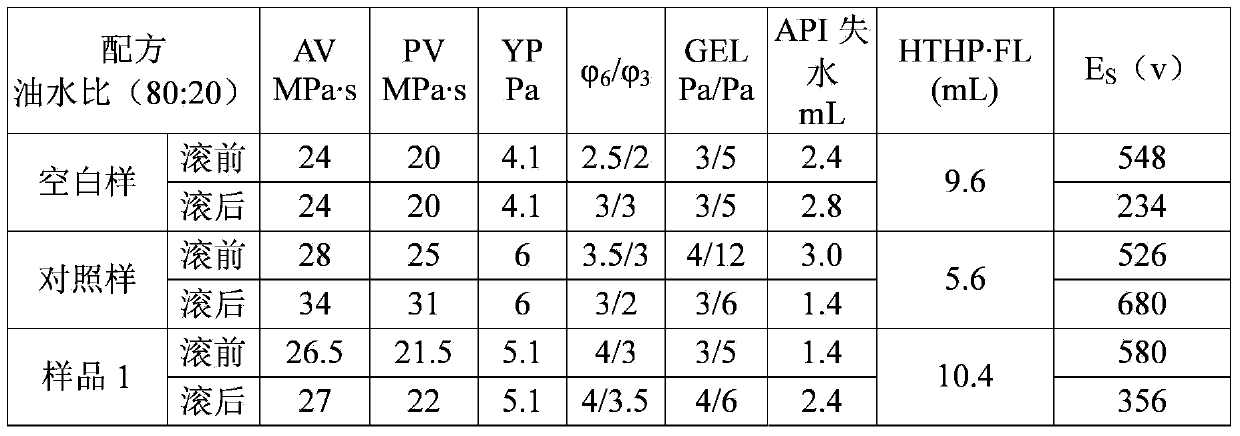

[0028] This embodiment provides a nano-plugging agent for oil-based drilling fluid, the nano-plugging agent includes: 40 g of styrene, 20 g of methyl methacrylate, 0.6 g of emulsifier sodium lauryl sulfate, deionized 140 g of water, 1.8 g of N,N'-methylenebisacrylamide, 0.069 g of sodium bisulfite, and 0.06 g of potassium persulfate.

[0029] The preparation method of the above-mentioned nanometer plugging agent for oil-based drilling fluid specifically comprises the following steps:

[0030] Step 1: Mix the emulsifier, N,N'-methylenebisacrylamide and deionized water, and stir evenly to obtain a mixture;

[0031] Step 2: add styrene and methyl methacrylate to the mixture, and emulsify for 20-30min at a stirring speed of 3000r / min to obtain a pre-emulsion;

[0032] Step 3: Add sodium bisulfite and potassium persulfate to the reaction kettle containing 20wt% pre-emulsion, heat up to 60°C and react for 20-30min, drop the remaining pre-emulsion, and react at 60°C for 3h to obtain...

Embodiment 2

[0035] This embodiment provides a nanometer plugging agent for oil-based drilling fluid, the nanometer plugging agent includes: 30 g of styrene, 30 g of methyl methacrylate, 0.6 g of sodium lauryl sulfate, and 140 g of deionized water , N,N'-methylenebisacrylamide 1.8g, sodium bisulfite 0.069g and potassium persulfate 0.06g.

[0036] The preparation method of the above-mentioned nanometer plugging agent for oil-based drilling fluid specifically comprises the following steps:

[0037] Step 1: with embodiment 1;

[0038] Step 2: the same as in Example 1, the difference is that the stirring rate is 4000r / min;

[0039] Step 3: Similar to Example 1, except that after dripping the remaining pre-emulsion, react at 70° C. for 4 hours to obtain a nano-plugging agent for oil-based drilling fluid with an average particle size of 80 nm.

Embodiment 3

[0041] This embodiment provides a nano-plugging agent for oil-based drilling fluid, the nano-plugging agent includes: 20 g of styrene, 40 g of methyl methacrylate, 0.6 g of sodium lauryl sulfate, and 140 g of deionized water , N,N'-methylenebisacrylamide 1.8g, sodium bisulfite 0.069g and potassium persulfate 0.06g.

[0042] The preparation method of the above-mentioned nanometer plugging agent for oil-based drilling fluid specifically comprises the following steps:

[0043] Step 1: with embodiment 1;

[0044] Step 2: the same as in Example 1, the difference is that the stirring rate is 5000r / min;

[0045] Step 3: Similar to Example 1, except that after dripping the remaining pre-emulsion, react at 80° C. for 5 hours to obtain a nano-plugging agent for oil-based drilling fluid with an average particle size of 60 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com