Preparation method for polymer matrix micron/nanometer packing filling modification compound premix particles

A composite premix and nanofiller technology, applied in the field of composite raw materials or premix particles, can solve the problems of high surface energy, filling and modification can not achieve the expected effect, and the performance of composite materials is degraded, and the molecular structure can be achieved. Improved regularity, uniform and controllable dimensions, and improved interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Weigh 60g of polyethersulfone (PES) particles and add them into N,N-dimethylformamide, stir them mechanically to fully dissolve them, and prepare 300ml of polyethersulfone homogeneous solution with a concentration of 0.2g / ml;

[0040] 2) Weigh 1g graphene oxide (GO), and make it dispersed in 100ml N,N-dimethylformamide, the preparation concentration is the graphene oxide dispersion liquid of 0.01g / ml, drop 0.05g (equivalent to 5wt% of the filler content) silane coupling agent KH550, in the dispersion process, magnetic stirring, ultrasonic pulverization each for 30 minutes, because the dispersion effect is not good, then add 0.05g (equivalent to 5wt% of the filler content) ten Sodium dialkyl sulfate is used as a surfactant, continue to stir for 30 minutes to disperse the dispersion evenly, then add it to the prepared PES solution, and stir for 30 minutes;

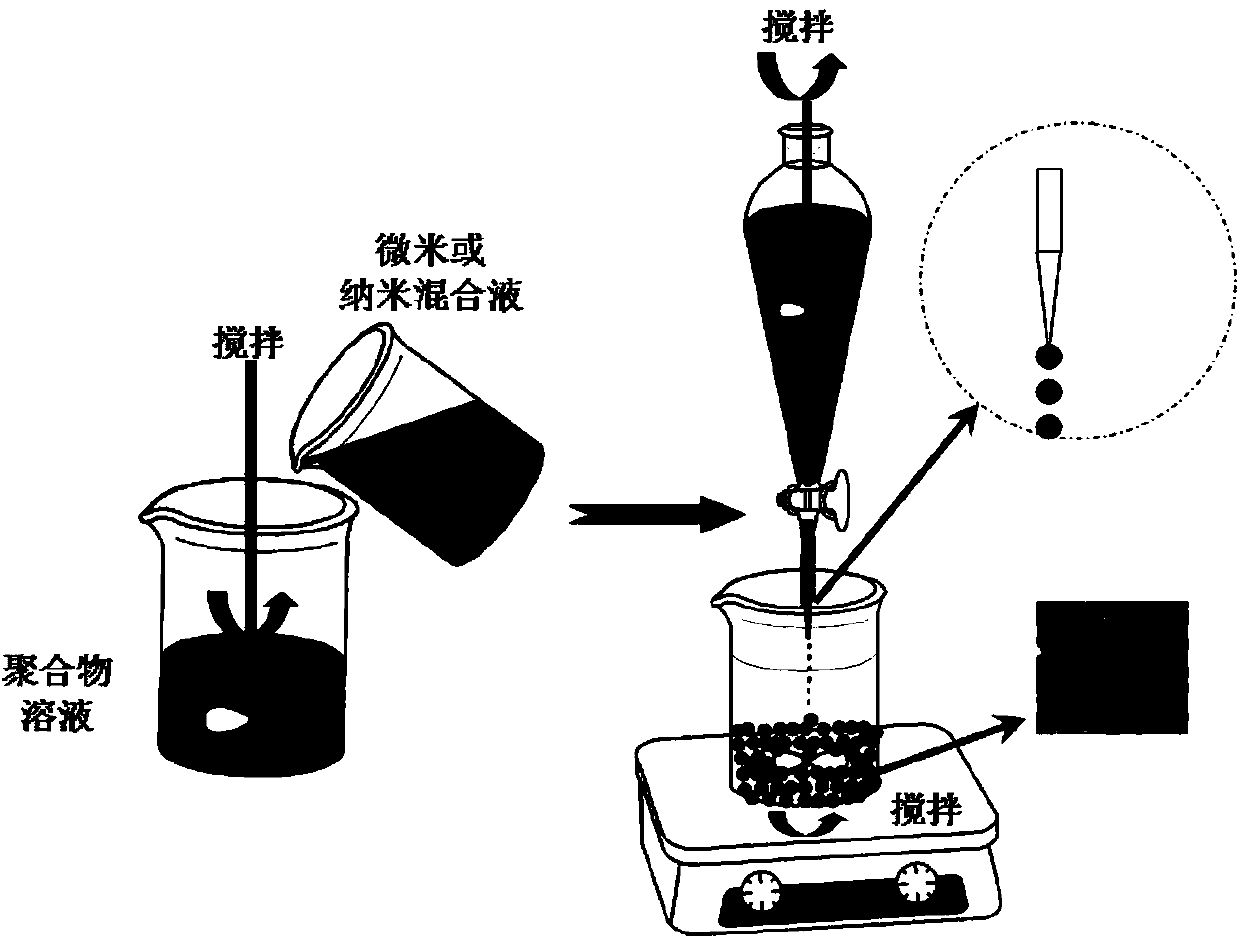

[0041] 3) Transfer the homogeneous mixed solution to figure 1 Continue to stir for 10 minutes in the device wit...

Embodiment 2

[0044] 1) Weigh 90g of polyethersulfone (PES) particles and add them to N,N-dimethylformamide, stir them mechanically to fully dissolve them, and prepare 900ml of polyethersulfone homogeneous solution with a concentration of 0.1g / ml;

[0045] 2) During the dissolution process of PES solution, weigh 30g CaCO 3 Disperse in N,N-dimethylformamide, stir mechanically, prepare 150ml concentration and be the calcium carbonate homogeneous dispersion liquid of 0.2g / ml, in the process of stirring and dispersing, drop 0.06g (equivalent to 0.2wt of filler content %) phthalate coupling agent;

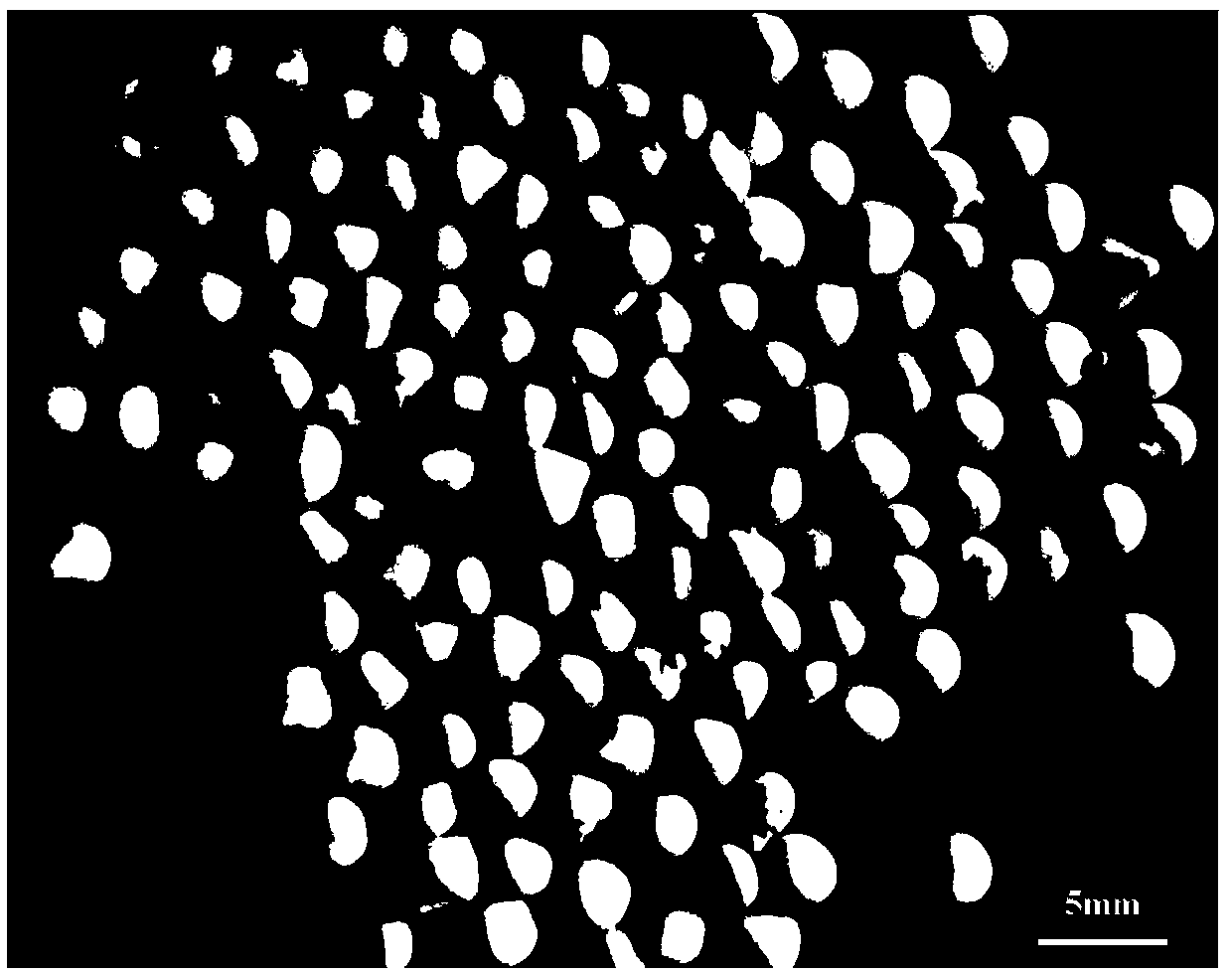

[0046] 3) Disperse evenly CaCO 3 Add the dispersion liquid into the dissolved PES solution and stir for 20 minutes; then transfer the mixed solution to the pellet preparation device with a pore diameter of 1000 μm below, and continue stirring after fixing it. After 10 minutes, slowly open the valve below the device to make The solution was continuously dripped into the deionized water at a distance...

Embodiment 3

[0049] 1) Weigh 90 g of bisphenol A polysulfone (PSF) and add it to N,N-dimethylacetamide solvent, mix and stir mechanically to prepare 900 ml of PSF homogeneous solution with a concentration of 0.1 g / ml;

[0050] 2) Weigh 2g of carbon nanotube (CNT) powder and disperse in 100ml of N,N-dimethylacetamide to prepare a carbon nanotube dispersion with a concentration of 0.02g / ml, first stir for 30 minutes, and then ultrasonically pulverize for 30 minutes Add it to the previously prepared PSF solution, stir continuously for 10 minutes, and then sonicate for 20 minutes to prepare a uniformly dispersed mixed solution;

[0051] 3) Transfer the mixed solution to a device with a pore diameter of 200 μm below and continue to stir, then slowly open the valve below the device so that the solution can be evenly dripped into the collector with deionized water at a distance of 5 cm below in the form of droplets ; Stir the deionized water evenly with a magnetic stirrer;

[0052] 4) After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com