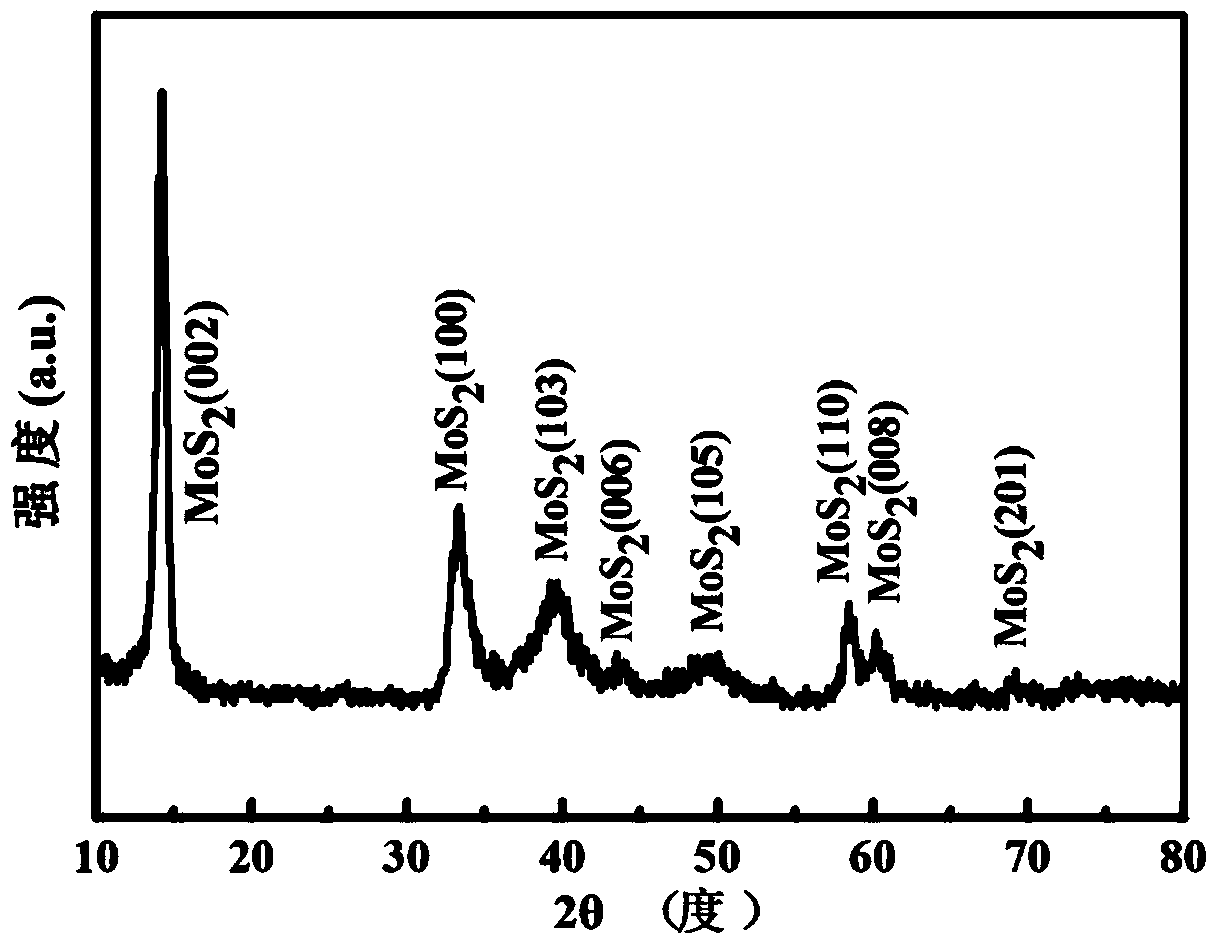

Nanosphere encapsulated MoS2 micron hollow sphere structure semiconductor material and preparation method thereof

A hollow sphere and nanosphere technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of harsh reaction conditions, high production cost, and unsuitable for large-scale industrial production. The method is simple, the cost is low, and the effect of reducing the requirements of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail in conjunction with the following specific examples and accompanying drawings, and the protection content of the present invention is not limited to the following examples. Without departing from the spirit and scope of the inventive concept, changes and advantages conceivable by those skilled in the art are all included in the present invention, and the appended claims are the protection scope. The process, conditions, reagents, experimental methods, etc. for implementing the present invention are general knowledge and common knowledge in the art except for the content specifically mentioned below, and the present invention has no special limitation content.

[0034] Example Preparation of MoS surrounded by nanospheres 2 Semiconductor materials with micron hollow sphere structure

[0035] The specific steps of preparation are as follows:

[0036] (1) Dissolve 0.2 g of sodium molybdate, 0.4 g of thioacetamide, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com