Refining method of titanium tetrachloride

A titanium tetrachloride and refining method technology, applied in the direction of titanium halide, etc., can solve the problems of vanadium content and unsatisfactory effect, and achieve the effect of easy cleaning, good vanadium removal effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

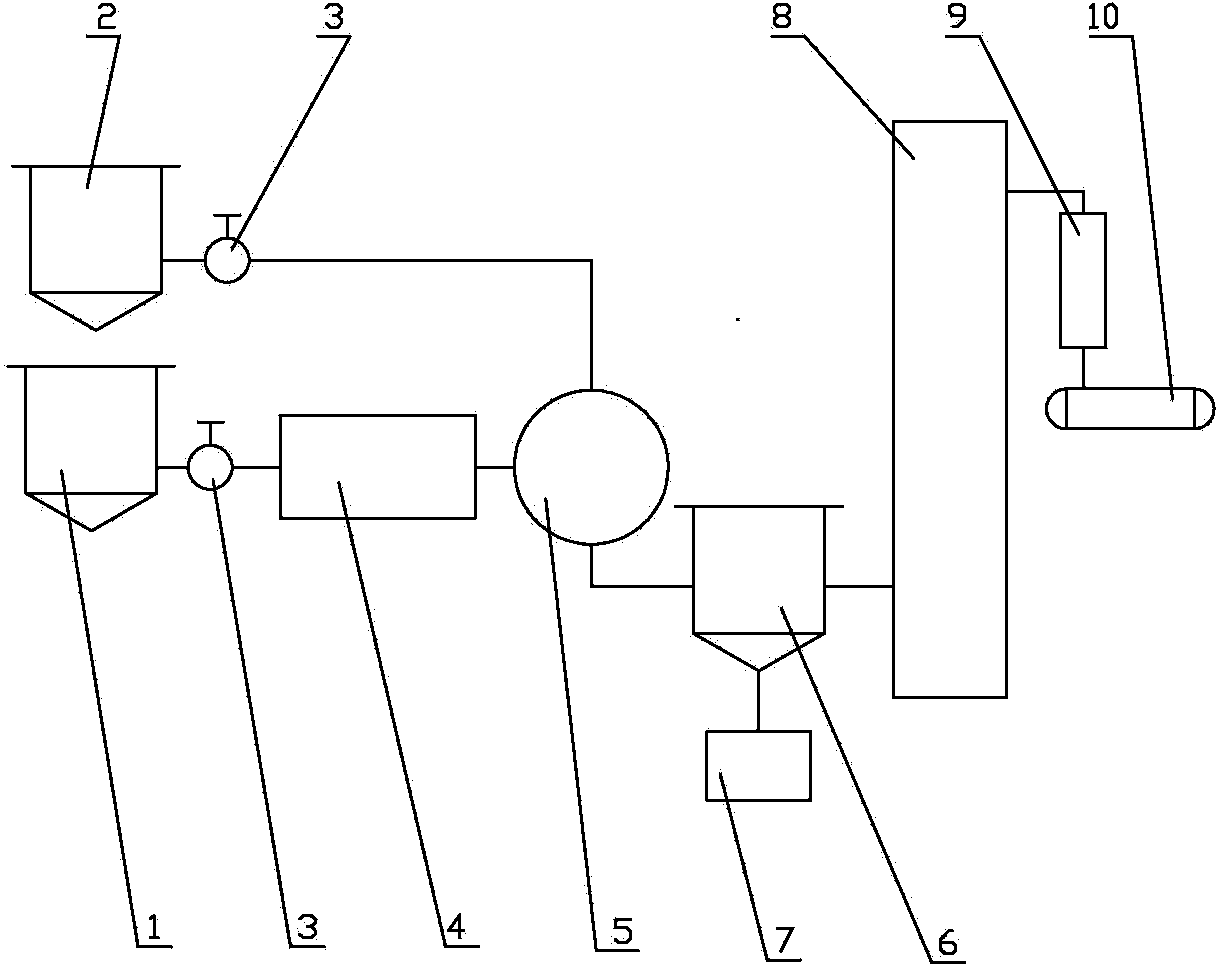

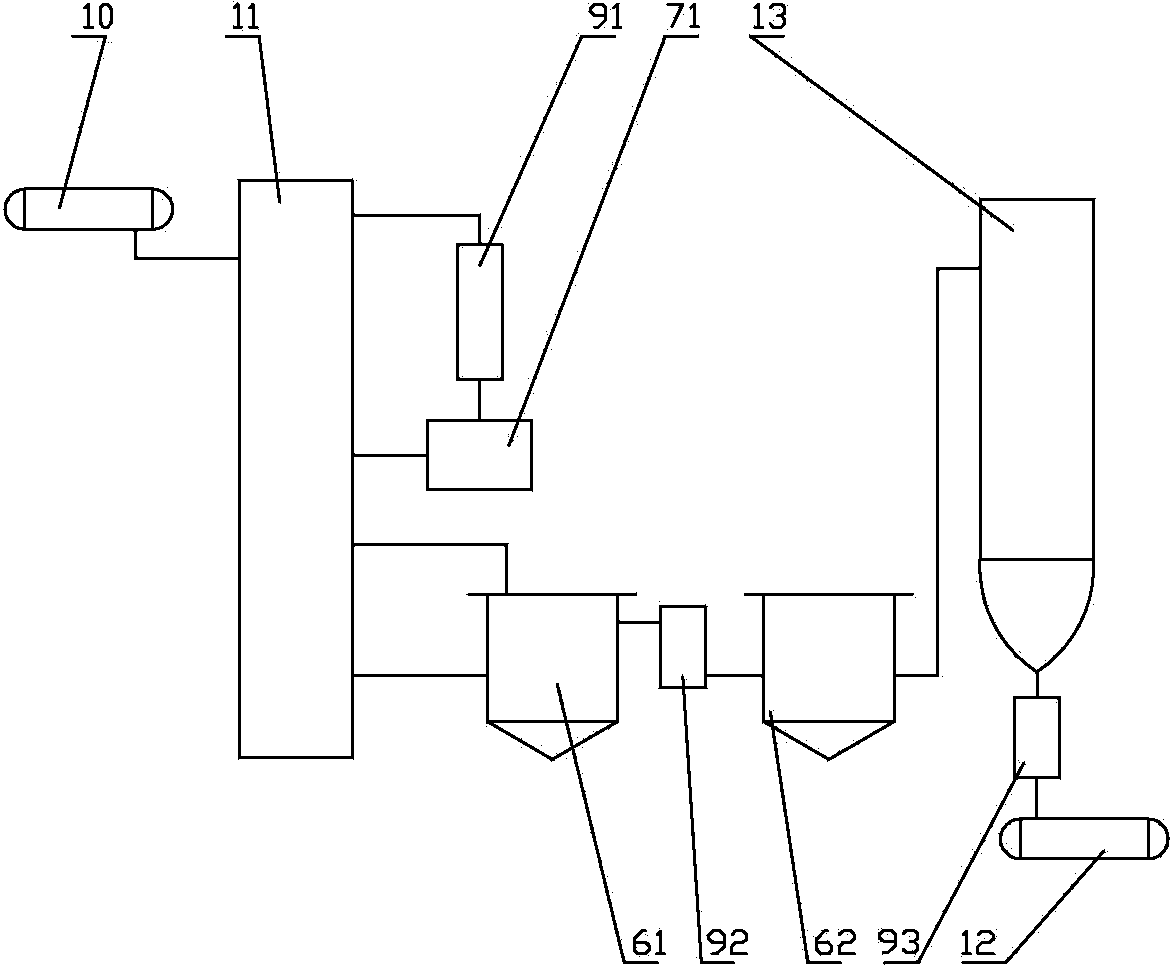

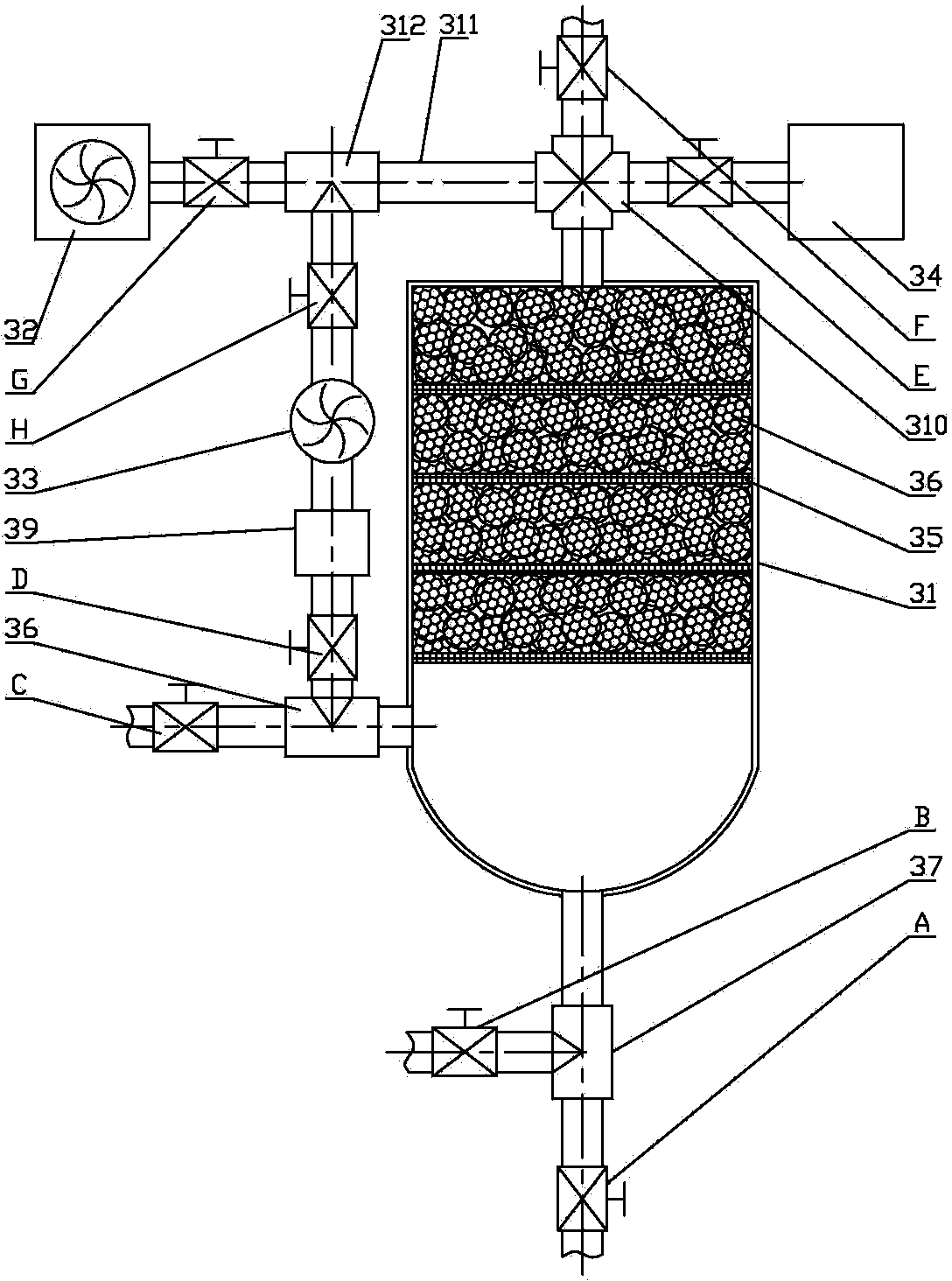

[0025] Example 1: Crude TiCl 4 The crude titanium head tank 1 is sent into the heater 4 through the flow valve 3, and the heater 4 makes the crude TiCl 4 heated to 120 °C, followed by crude TiCl 4 Sent to the mixer 5, 100 parts of paraffin oil, 80 parts of saturated fatty acid, 2 parts of p-phenylenediamine, 0.3 part of 2,2,4-trimethyl 1,2-dihydroquinoline polymer were mixed The organic solution is sent into the mixer 5, and the organic solution and the hot TiCl are mixed in the mixer 5. 4 The mixing ratio is 1:1, paraffin oil and saturated fatty acid will be carbonized to form activated carbon to convert VOCl 3 Reduction and adsorption of other impurities, p-phenylenediamine, 2,2,4-trimethyl 1,2-dihydroquinoline polymers can control the reaction rate and help crude TiCl 4 The impurities in the mixture are separated out, and then the material is sent to the first still 6 for distillation, and most of the vanadium-containing impurities are discharged into the vanadium mud ta...

Embodiment 2

[0028] Example 2: Crude TiCl 4 The crude titanium head tank 1 is sent into the heater 4 through the flow valve 3, and the heater 4 makes the crude TiCl 4 heated to 130 °C, followed by crude TiCl 4 It is sent to the mixer 5; 100 parts of paraffin oil, 90 parts of saturated fatty acid, 3 parts of p-phenylenediamine, 0.4 part of 2,2,4-trimethyl 1,2-dihydroquinoline polymer are mixed The organic solution is sent into the mixer 5, and the organic solution and the hot TiCl are mixed in the mixer 5. 4 The mixing ratio is 1:1, paraffin oil and saturated fatty acid will be carbonized to form activated carbon to convert VOCl 3 Reduction and adsorption of other impurities, p-phenylenediamine, 2,2,4-trimethyl 1,2-dihydroquinoline polymers can control the reaction rate and help crude TiCl 4 The impurities in the mixture are separated out, and then the material is sent to the first still 6 for distillation, and most of the vanadium-containing impurities are discharged into the vanadium m...

Embodiment 3

[0031] Example 3: Crude TiCl 4 The crude titanium head tank 1 is sent into the heater 4 through the flow valve 3, and the heater 4 makes the crude TiCl 4 heated to 140 °C, followed by crude TiCl 4 It is sent to the mixer 5; 100 parts of paraffin oil, 100 parts of saturated fatty acid, 4 parts of p-phenylenediamine, 0.5 part of 2,2,4-trimethyl 1,2-dihydroquinoline polymer are mixed The organic solution is sent into the mixer 5, and the organic solution and the hot TiCl are mixed in the mixer 5. 4 The mixing ratio is 1:1, paraffin oil and saturated fatty acid will be carbonized to form activated carbon to convert VOCl 3 Reduction and adsorption of other impurities, p-phenylenediamine, 2,2,4-trimethyl 1,2-dihydroquinoline polymers can control the reaction rate and help crude TiCl 4 The impurities in the mixture are separated out, and then the material is sent to the first still 6 for distillation, and most of the vanadium-containing impurities are discharged into the vanadium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com