One-machine double-wire self-heat-preservation wallboard production system and operating method

A production system and self-insulation technology, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of time-consuming and laborious construction, inability to prevent fire prevention, difficulty in large-scale industrial production, etc., and achieve scientific layout and design Reasonable, improve the utilization rate, the effect of fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

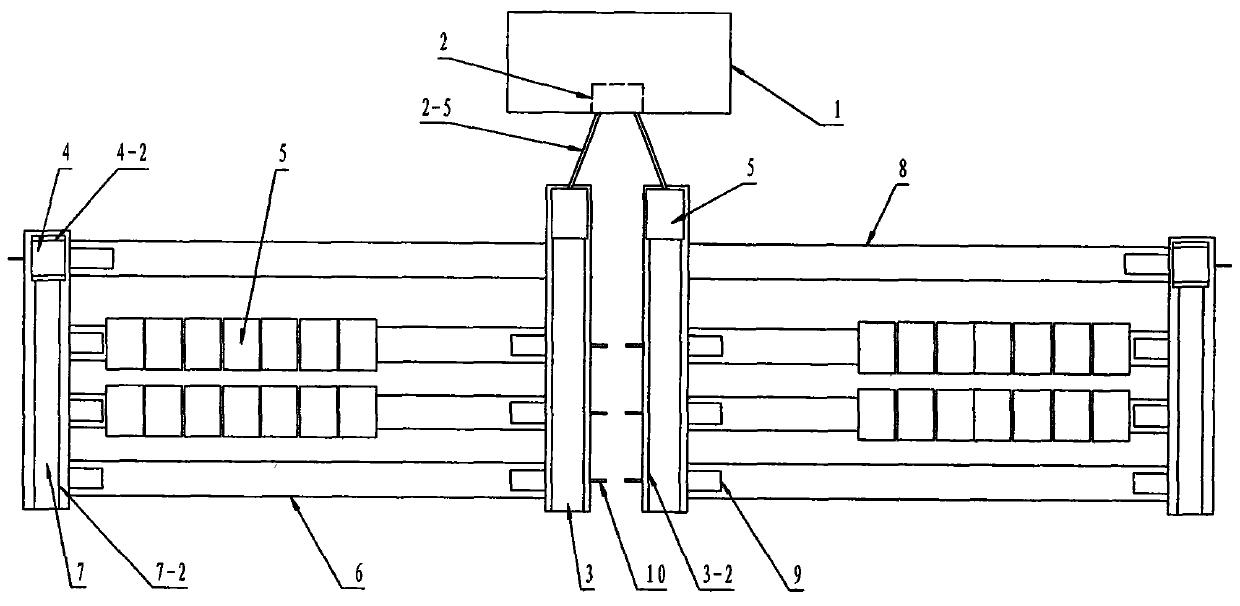

[0026]One side of the light particle processing system 1 is equipped with a material distribution device 2, and the two outlets of the material distribution device 2 are respectively equipped with a feeding pipe 2-5, and one side of the light particle processing system 1 corresponds to two feeding pipes 2-5 Two sets of rectangular material circulation cycle production systems are set up, each set of rectangular material circulation cycle production system is composed of mold connecting track 3-2, mold feeding track 7-2, static track 6 and mold disassembly and closing track 8, two parallel mold connecting Tunnel 3 is set correspondingly to two material conveying pipes 2-5, a pair of joint mold rails 3-2 is set in the mold joint tunnel 3, a ferry car 4 is arranged above the pair of mold joint tracks 3-2, and two sides of the mold joint tunnel 3 Two parallel mold delivery tunnels 7 are arranged correspondingly, a pair of mold delivery rails 7-2 are arranged in the mold delivery tu...

Embodiment 2

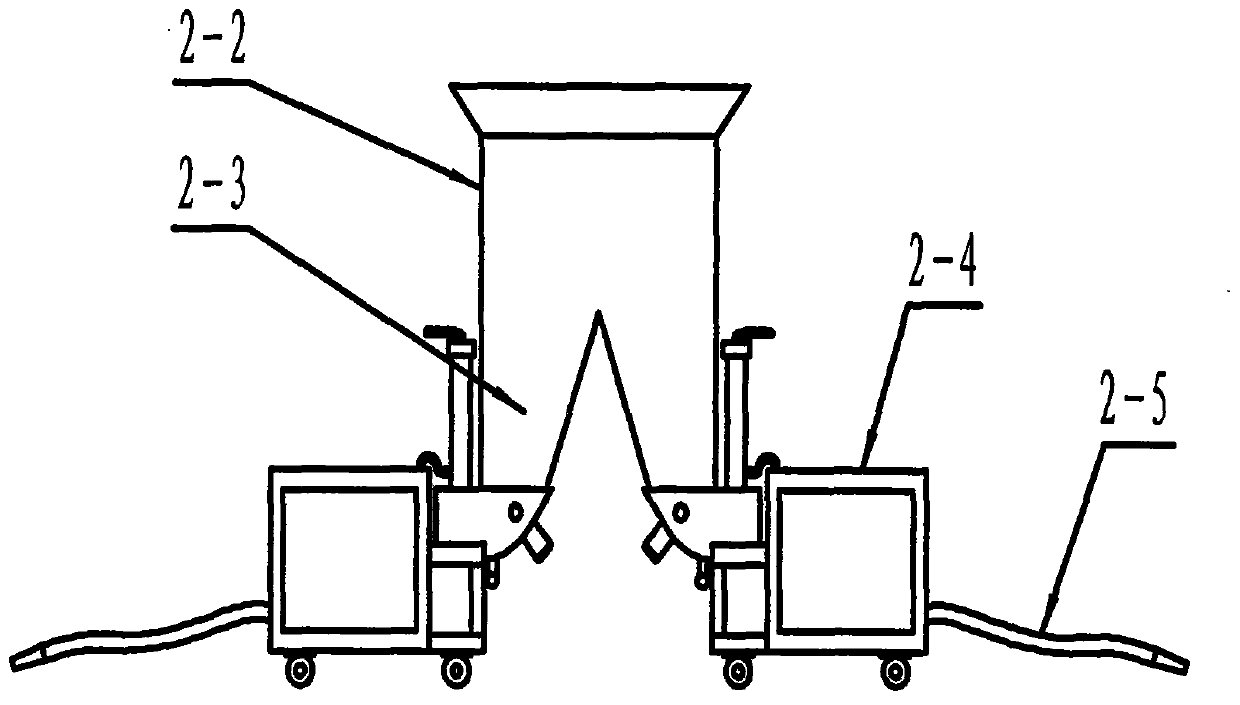

[0028] Described material distributing device 2 is, two sides below the distribution hopper 2-2 are provided with discharge cylinder 2-3, and two discharge cylinders 2-3 are set correspondingly with two conveying pumps 2-4, and the discharge cylinder 2-2 of distribution hopper 2-2 The feed end is set corresponding to the discharge end of the light particle processing system 1, and the feed port of the delivery pump 2-4 is provided with a feed pipe 2-5.

Embodiment 3

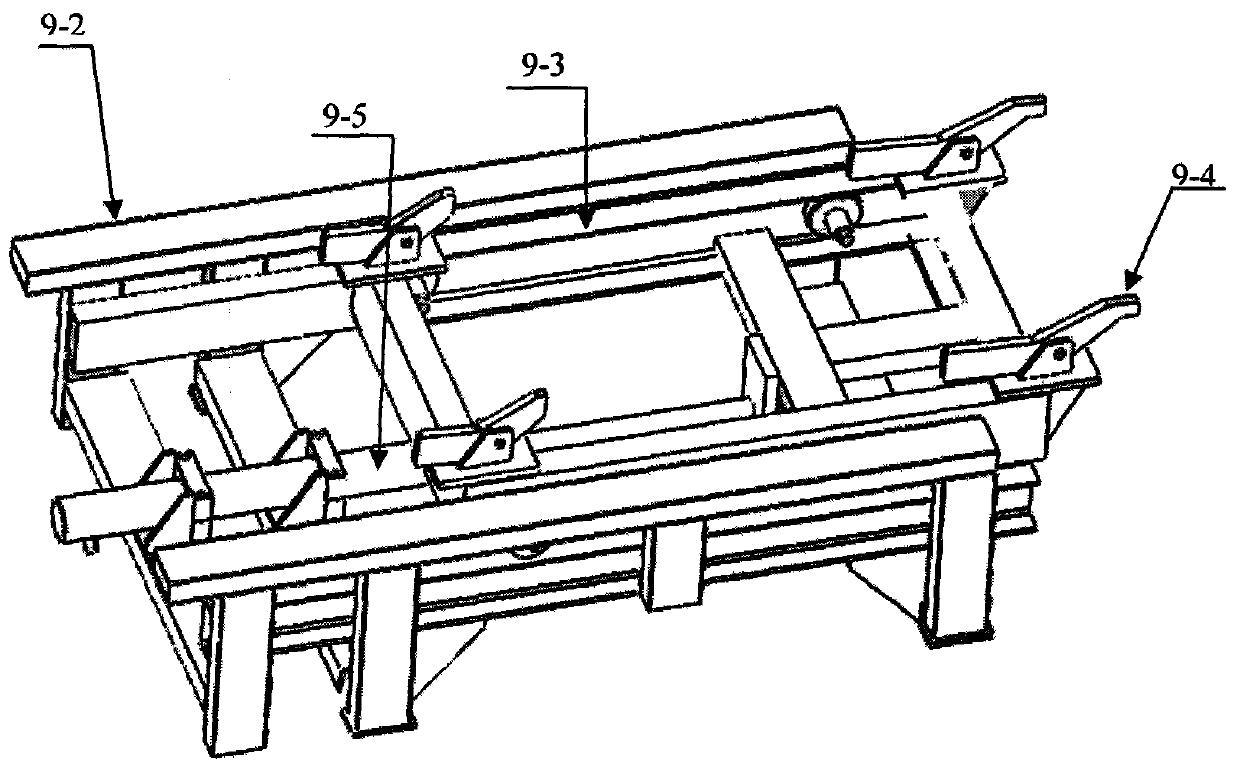

[0030] A trolley bracket 9-2 is set in the transition zone 9, a trolley 9-3 is slidingly set in the trolley bracket 9-2, and a hydraulic cylinder 9-3 is set between the middle part of the trolley bracket 9-2 and the trolley 9-3. 5. Movable push heads 9-4 are set at the four corners of the cart 9-3. The movable push heads 9-4 are composed of a short push head and a long push head, and the included angle between the short push head and the long push head is 100-130°. degree, the movable push head 9-4 swings left and right with the central point of the angle between the short push head and the long push head as the support point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com